A Method for Improving the Stability of Coalbed Methane Surface Drilling

A technology for ground drilling and coalbed methane, which is applied in drilling equipment and methods, drilling with liquid/gas jets, drilling equipment, etc., can solve problems such as closed-hole and wellbore deformation, and achieves low cost, strong impact absorption ability, good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

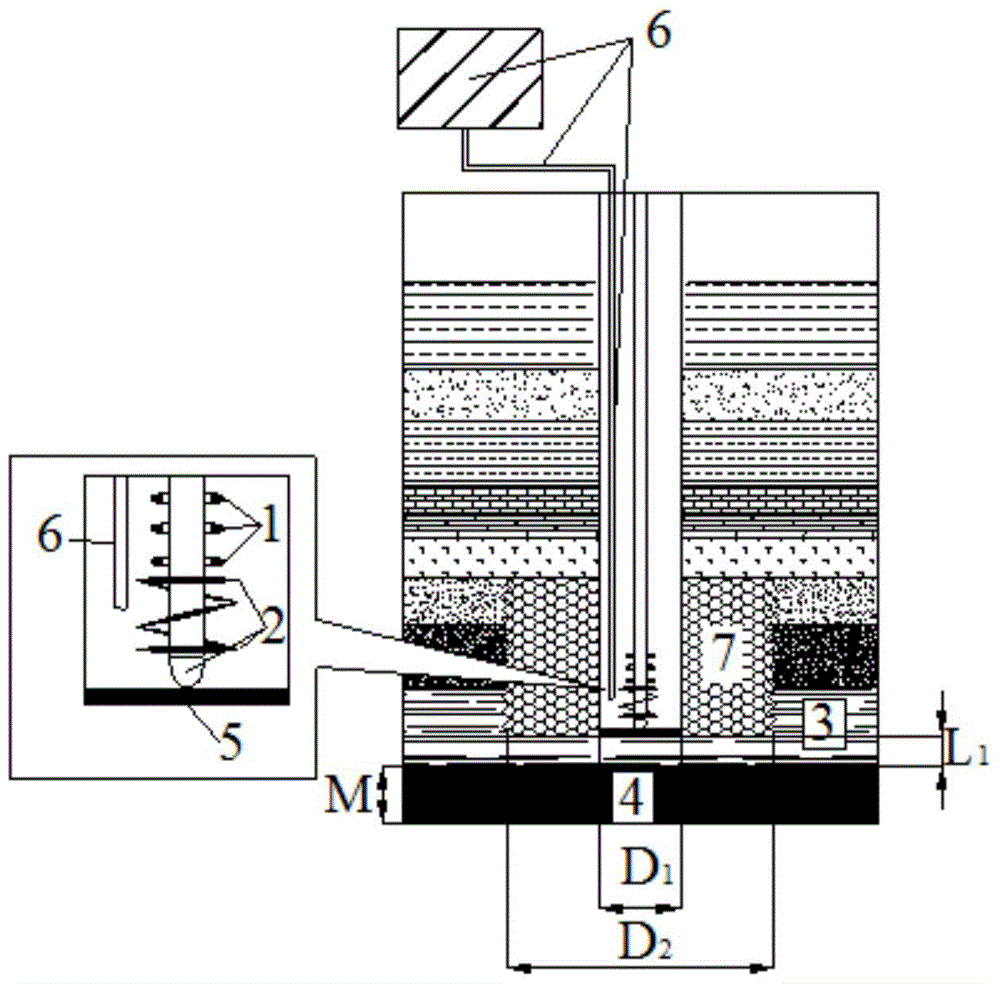

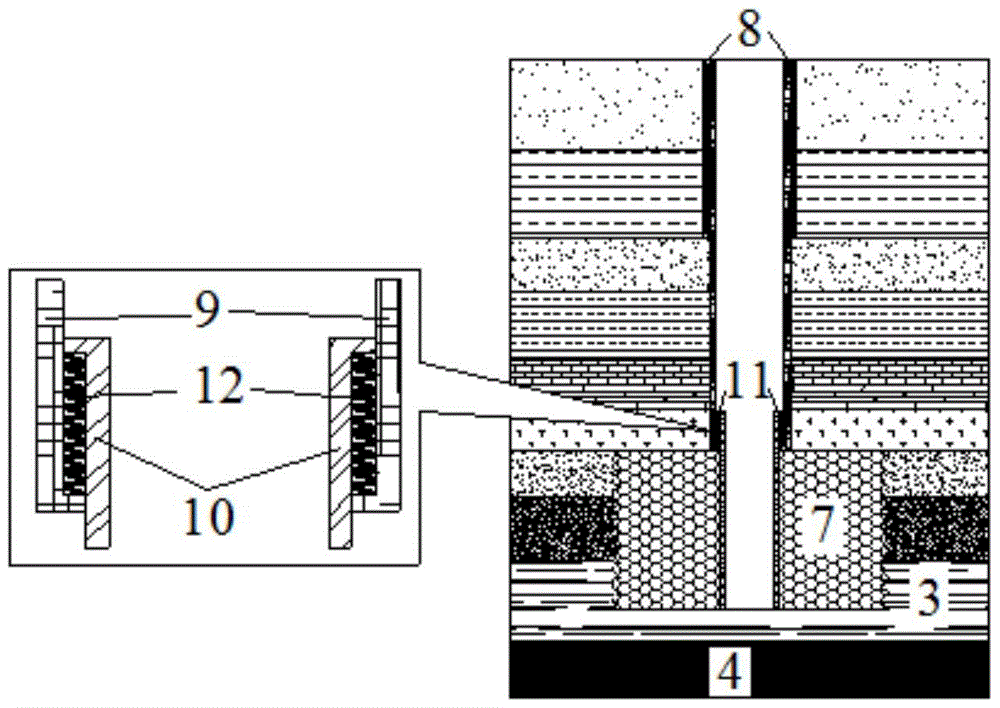

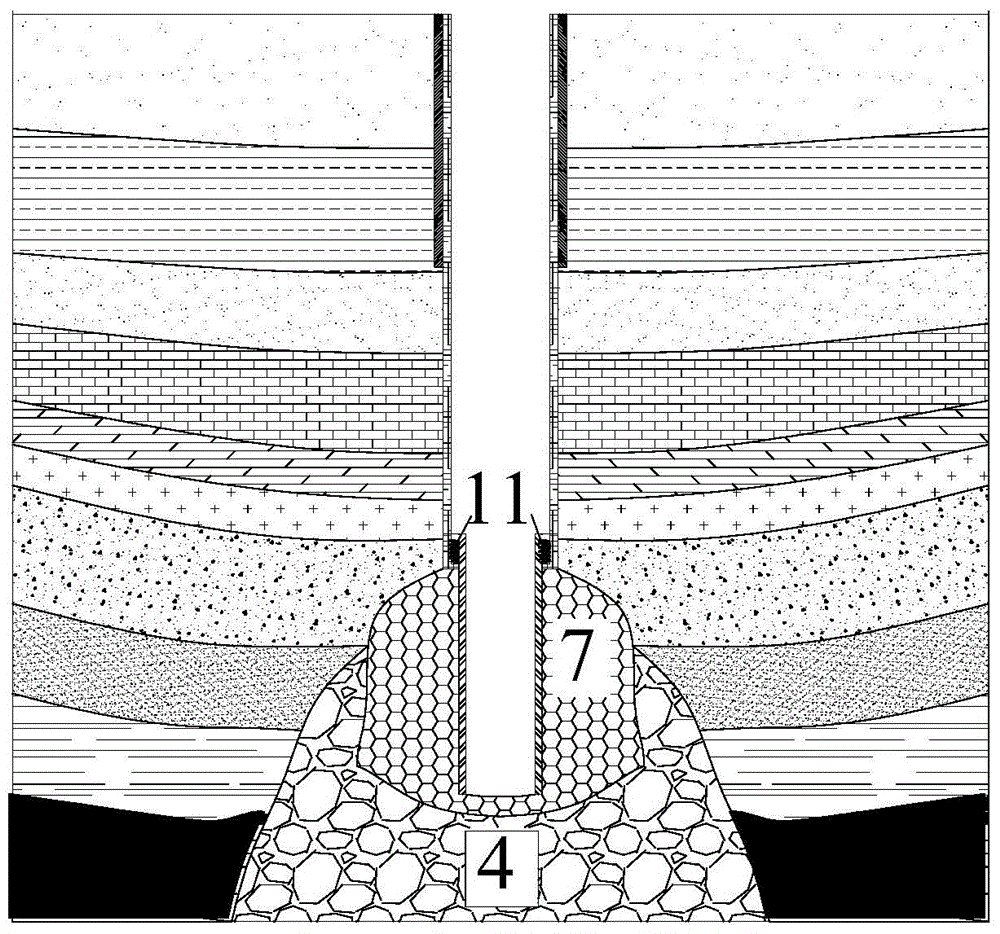

[0034] (1) if figure 1 As shown, based on the mature drilling equipment in the field of coalbed methane development, the drill bit 2 with the hydraulic jet drilling equipment 1 is used to drill from the surface, and the drilling diameter is D 1 ,D 1 is 2 meters, the drilling head 5 is located in the direct roof 3, and the distance from the roof of the coal seam 4 is L 1 , L 1 It is 4m.

[0035] (2) Use the empirical formula for the height of the caving zone in coal mines to determine the height of the caving zone after mining the coal seam, and then determine the height of the expansion section according to the height of the caving zone.

[0036] (3) The inclination angle of the coal seam is less than 54°, the compressive strength of direct top 3 is σ﹤20MPa, and the height of the caving zone is H 1 =2M, M is the mining height, and its value is 2 meters; Utilize hydraulic jet drilling equipment 1 to start expanding the well from 5 places of the drilling well head, the expan...

Embodiment 2

[0043] Steps (1), (2), (4) to (7) are the same as in Example 1, except for step (3), the specific operation is as follows: the inclination angle of the coal seam is less than 54°, and the compressive strength of the direct top 3 is 20MPa≤ σ≤40MPa, height of caving zone H 2 =4M, M is the mining height, and its value is 2 meters; Utilize hydraulic jet drilling equipment 1 to start expanding the well from 5 places of the drilling well head, the expanding well height is 4M or 8 meters, and the expanding well diameter is D 2 , take the borehole diameter D 1 10 times the value, that is, the expansion diameter is 20 meters.

Embodiment 3

[0045] Steps (1), (2), (4) to (7) are the same as in Example 1, except for step (3), the specific operation is as follows: the inclination angle of the coal seam is less than 54°, and the compressive strength of the direct top 3 is 40MPa≤ σ≤60MPa, height of caving zone H 3 =5M, M is the mining height, and its value is 2 meters; Utilize hydraulic jet drilling equipment 1 to start expanding the well from 5 places of the drilling well head, the expanding well height is 2M or 10 meters, and the expanding well diameter is D 2 , take the borehole diameter D 1 10 times the value, that is, the expansion diameter is 20 meters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com