Coal gasification device and process capable of combusting organic effluent sewage

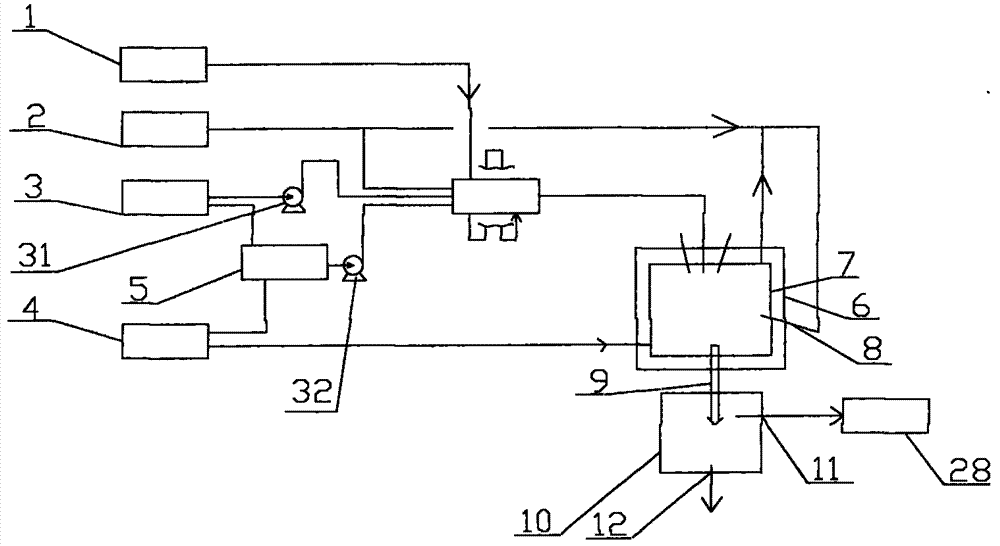

A technology for coal gasification and sewage, applied in the field of pressurized pulverized coal gasification, can solve the problems of unreasonable number and arrangement of nozzles, imperfect oxygen adding position, single feeding method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

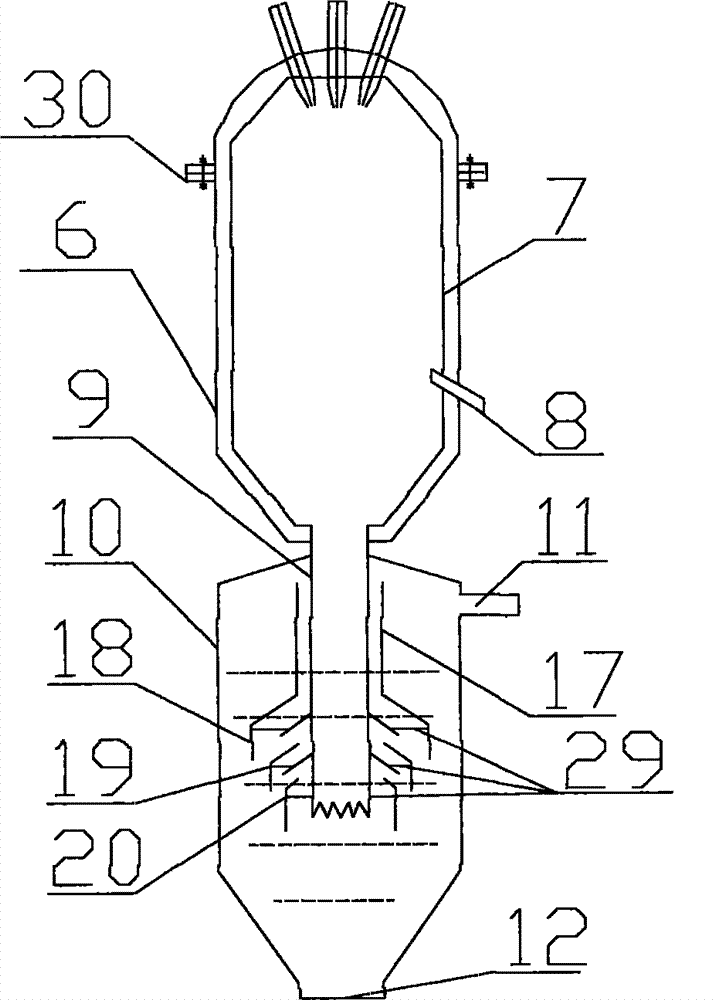

Method used

Image

Examples

Embodiment 1

[0092] A kind of technology of coal gasification device, this technology adopts dry coal powder organic waste water incineration method to produce synthetic gas, and its method steps are as follows:

[0093] a, close the fifth valve 25, open the first valve 21, the second valve 22, the third valve 23, the fourth valve 24, the sixth valve 26, and the seventh valve 27;

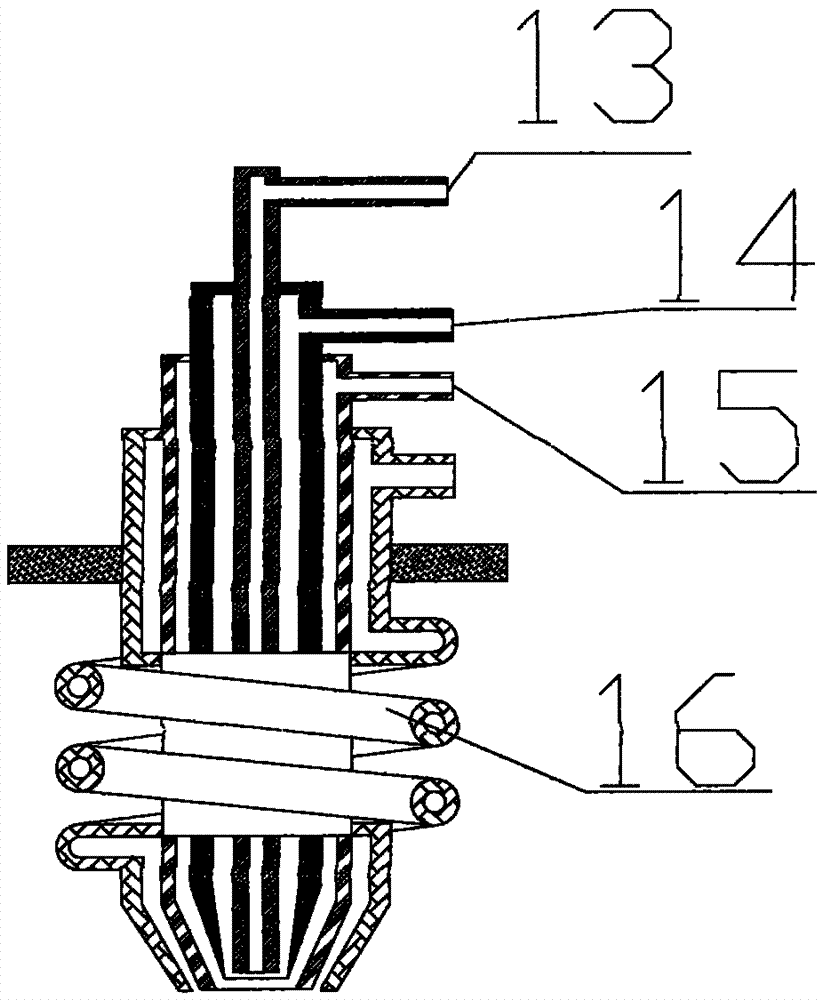

[0094] b. The flow rate in the dry pulverized coal storage tank 3 is 100t / h, and the dry pulverized coal with a particle size of 120-150 microns is pressurized by the first pressurizing pump 31 to 6.5-6.6MPa and then passes through the third valve 23 and the fourth valve 24 Delivered to the second passage 14 and the third passage 15 of the burner;

[0095] c. Oxygen in the oxygen storage tank 2 with a purity ≥ 99.6% and a pressure of 6.6-6.7 MPa enters the first channel 13 of the burner and the oxygen-increasing nozzle 8 respectively, wherein the flow rate is 45000 Nm 3 / h of oxygen through the first valve 21, ...

Embodiment 2

[0101] A kind of technology of coal gasification device, this technology adopts coal-water slurry organic waste water incineration method to produce synthetic gas, and its method steps are as follows:

[0102] a, close the third valve 23, open the first valve 21, the second valve 22, the fourth valve 24, the fifth valve 25, the sixth valve 26, and the seventh valve 27;

[0103]b. The flow rate in the dry pulverized coal storage tank 3 is 100t / h, and the dry pulverized coal with a particle size of 120-150 microns is sent to the coal-water slurry storage tank 5, and the water with a flow rate of 40t / h in the water storage tank 4 is sent to the water In the coal slurry storage tank 5, water and dry coal powder are mixed in the coal water slurry storage tank 5 to make a coal water slurry with a concentration of 63-65%, which is pressurized to 6.4-6.5MPa by the second booster pump 32 , sent to the third channel 15 and the second channel 14 of the burner respectively through the fif...

Embodiment 3

[0110] A process for a coal gasification device, the process uses dry and wet materials, organic waste water and sewage to burn with a burner to produce synthesis gas, and the method steps are as follows:

[0111] a, close the fourth valve 24, open the first valve 21, the second valve 22, the third valve 23, the fifth valve 25, the sixth valve 26, and the seventh valve 27;

[0112] b. Dry pulverized coal with a particle size of 120-150 microns in the dry pulverized coal storage tank 3 respectively enters the second channel 14 of the burner, the third channel 15 and the coal-water slurry storage tank 5, and the dry pulverized coal with a flow rate of 50t / h passes through After the first booster pump 31 pressurizes to 6.5-6.6MPa, it passes through the third valve 23, and the fourth valve 24 sends it to the second channel 14 and the third channel 15 of the burner; the dry pulverized coal with a flow rate of 50t / h is sent to In the coal water slurry storage tank 5;

[0113] c. Ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com