Preparation method of high-temperature oil-coal slurry

A technology of oil-coal slurry and high-temperature oil, applied in the field of preparation of high-temperature oil-coal slurry, to achieve the effects of easy implementation, normal use, and reduced mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

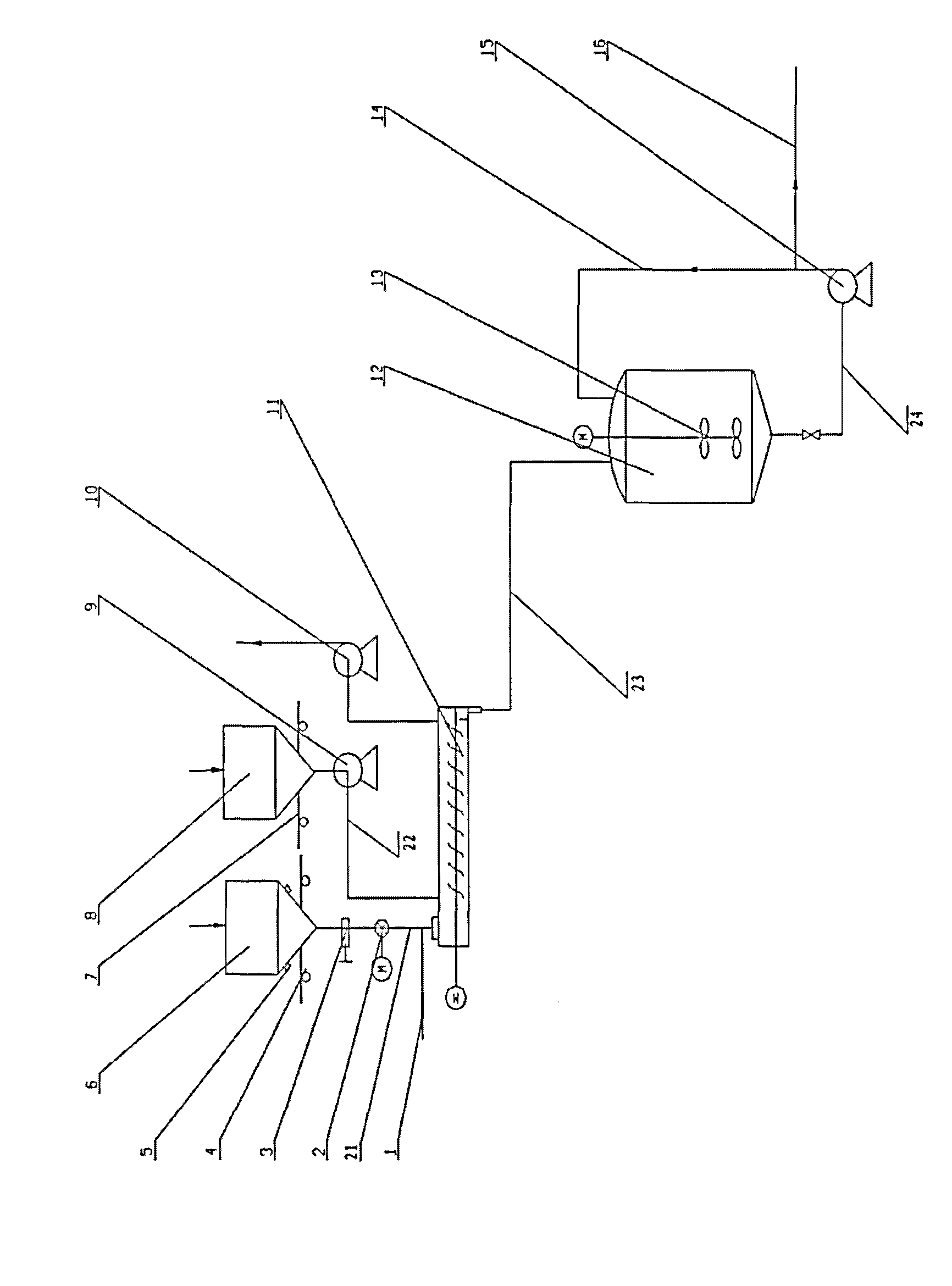

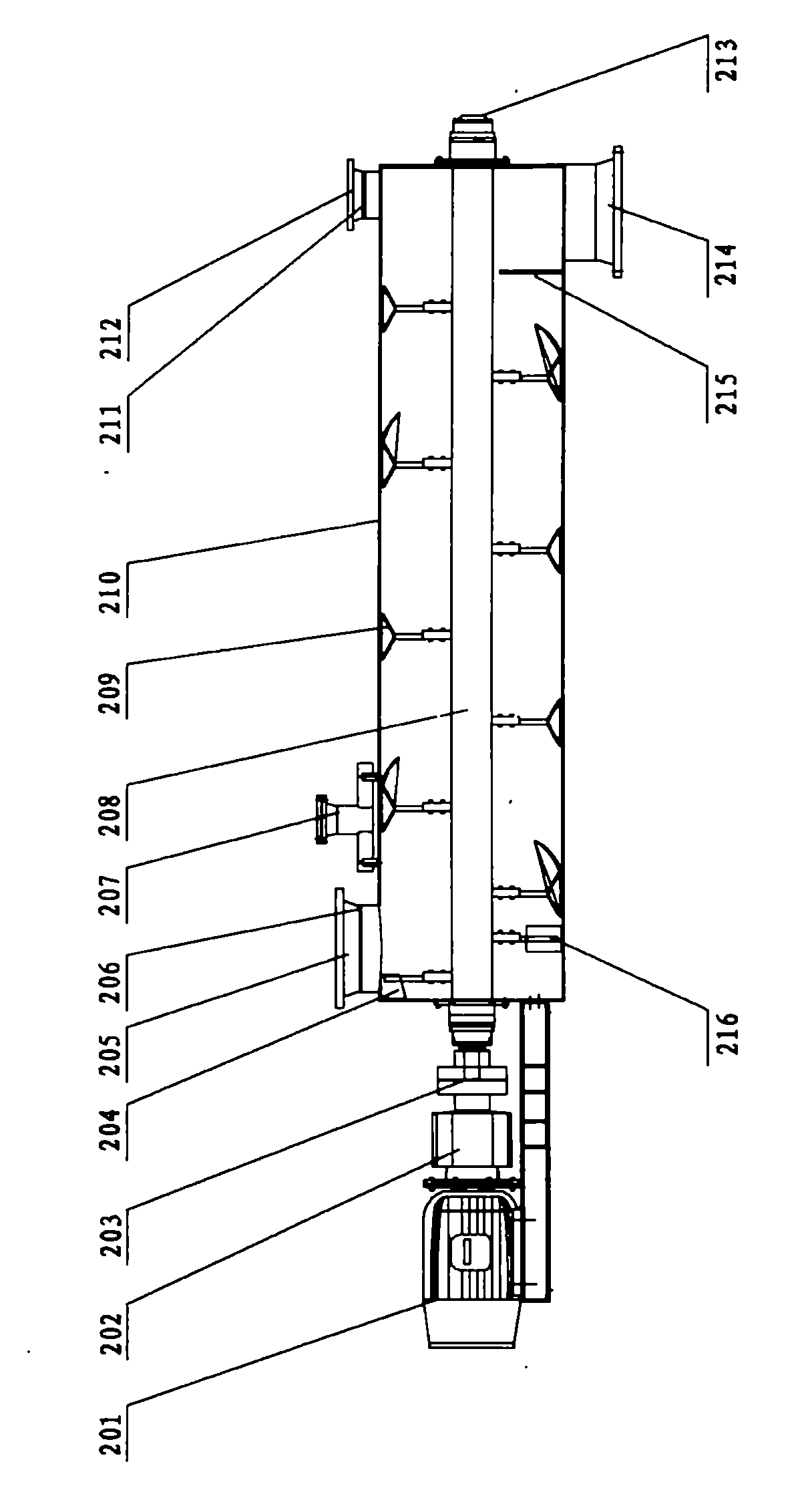

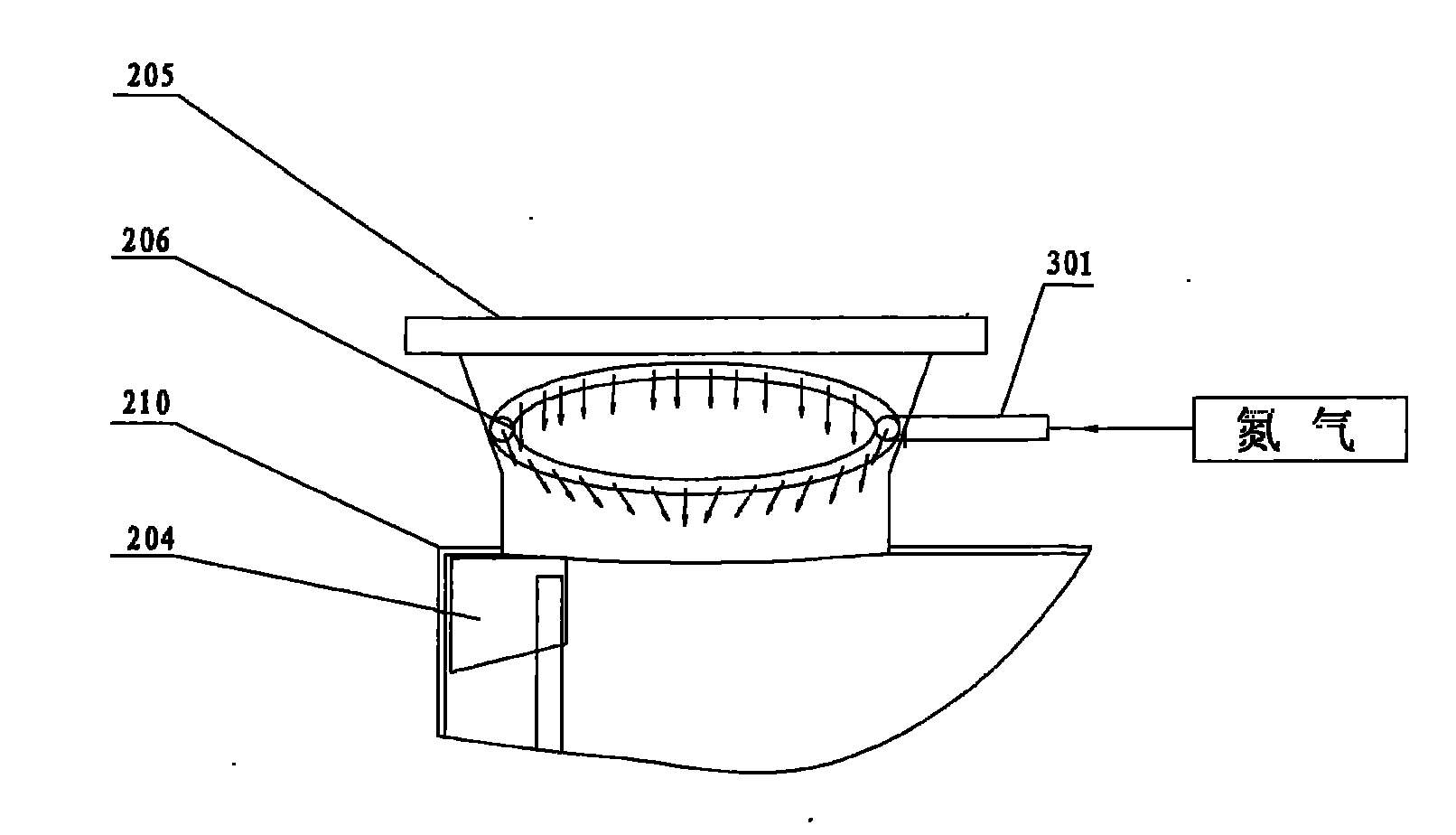

Method used

Image

Examples

Embodiment 1

[0043] Store the prepared pulverized coal particles less than or equal to 200 mesh (that is, less than or equal to 70 microns) in the pulverized coal storage tank. Control; according to the required configuration of 45% coal slurry concentration, continuously add coal powder in the horizontal solid-liquid mixer preferably used in the present invention in an amount of 94.66t / h, and control the addition of high-temperature solvent oil by a solvent weighing instrument , transported to the solid-liquid mixer by the solvent oil feeding pump in an amount of 100t / h under pressure. The amount of pulverized coal added is adjusted by controlling the rotation speed of the unloading valve through the DCS system, and it is added in proportion to the solvent at the same time. The vibrator on the pulverized coal feeding tank operates once every 2 minutes, and the nitrogen purge pipe in the pulverized coal feeding port is regularly opened every 3 minutes. Turn on the motor of the solid-liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com