An intelligent coal yard monitoring method and a monitoring system

A coal yard and coal transportation technology, applied in the field of intelligent monitoring and management of coal yards, can solve the problems of manpower consumption, increased production costs, and complicated coal incoming situations, and achieve the effects of reducing manual intervention, prolonging service life, and reducing labor input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

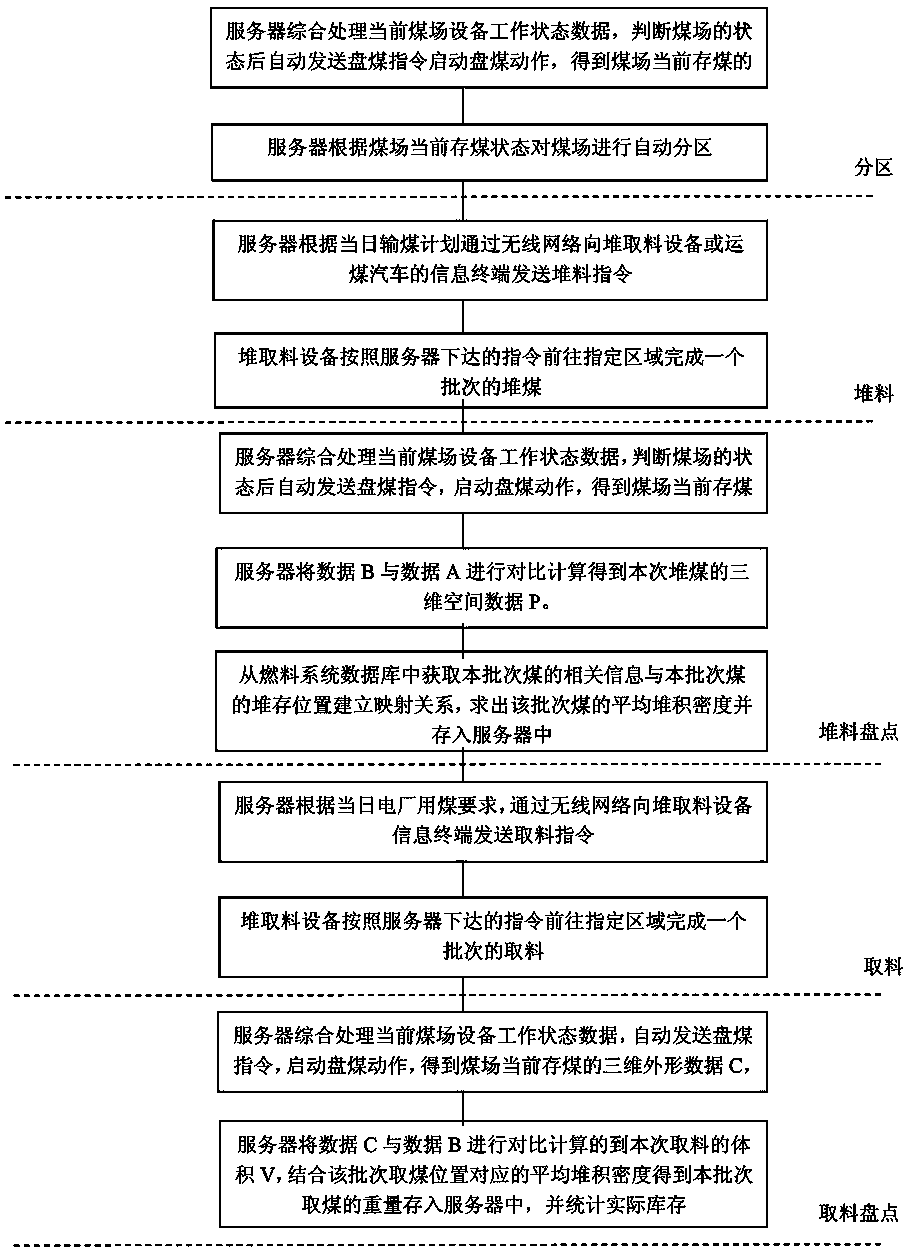

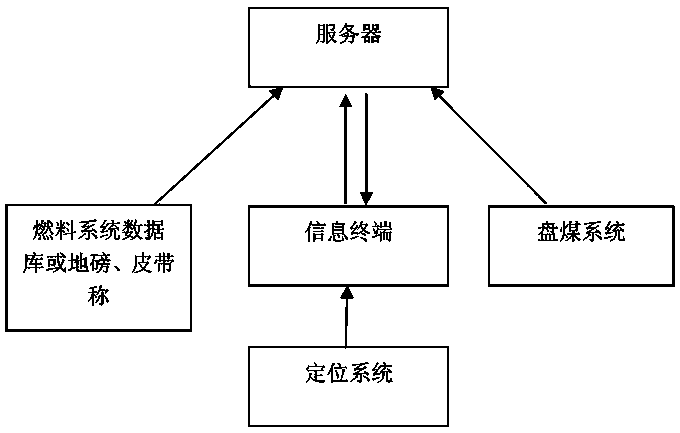

[0061] like figure 1 As shown, a kind of intelligent coal yard monitoring method of the present invention comprises:

[0062] S1. Zoning: divide the coal yard into areas;

[0063] Coal yard zoning is to divide the coal yard plane longitudinally into several areas, the purpose of which is to stack fuel according to the quality, the same type of coal is stacked in the same area, and the quality of coal stacked in adjacent areas is similar. When the smart coal yard is running for the first time, an initial manual partition is performed according to the current coal storage status of the coal yard, and the coal yard partition will be automatically adjusted after the system runs.

[0064] In the specific operation, the partition adjustment is based on the coal transportation plan and the coal yard partition capacity. When the remaining c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com