Method for extracting gas from coal seam roof complex branched well

A coal seam roof and gas drainage technology, which is applied in the field of gas drainage in complex branch wells on the coal seam roof, can solve the problems of high cost, contradiction between drainage and excavation, safety accidents, etc., to reduce the gas content of the coal seam and save the time of gas drainage , the effect of reducing the gas content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

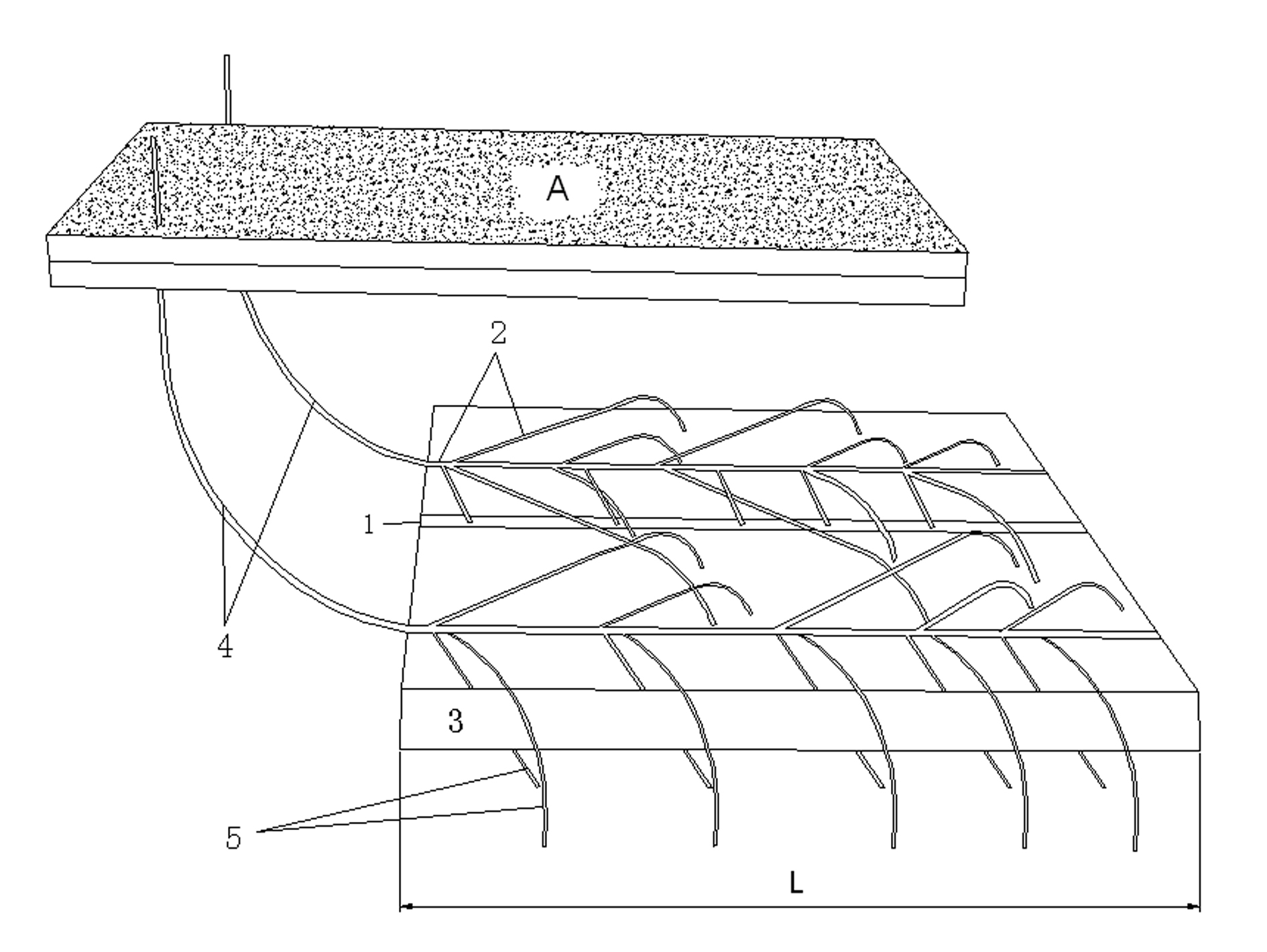

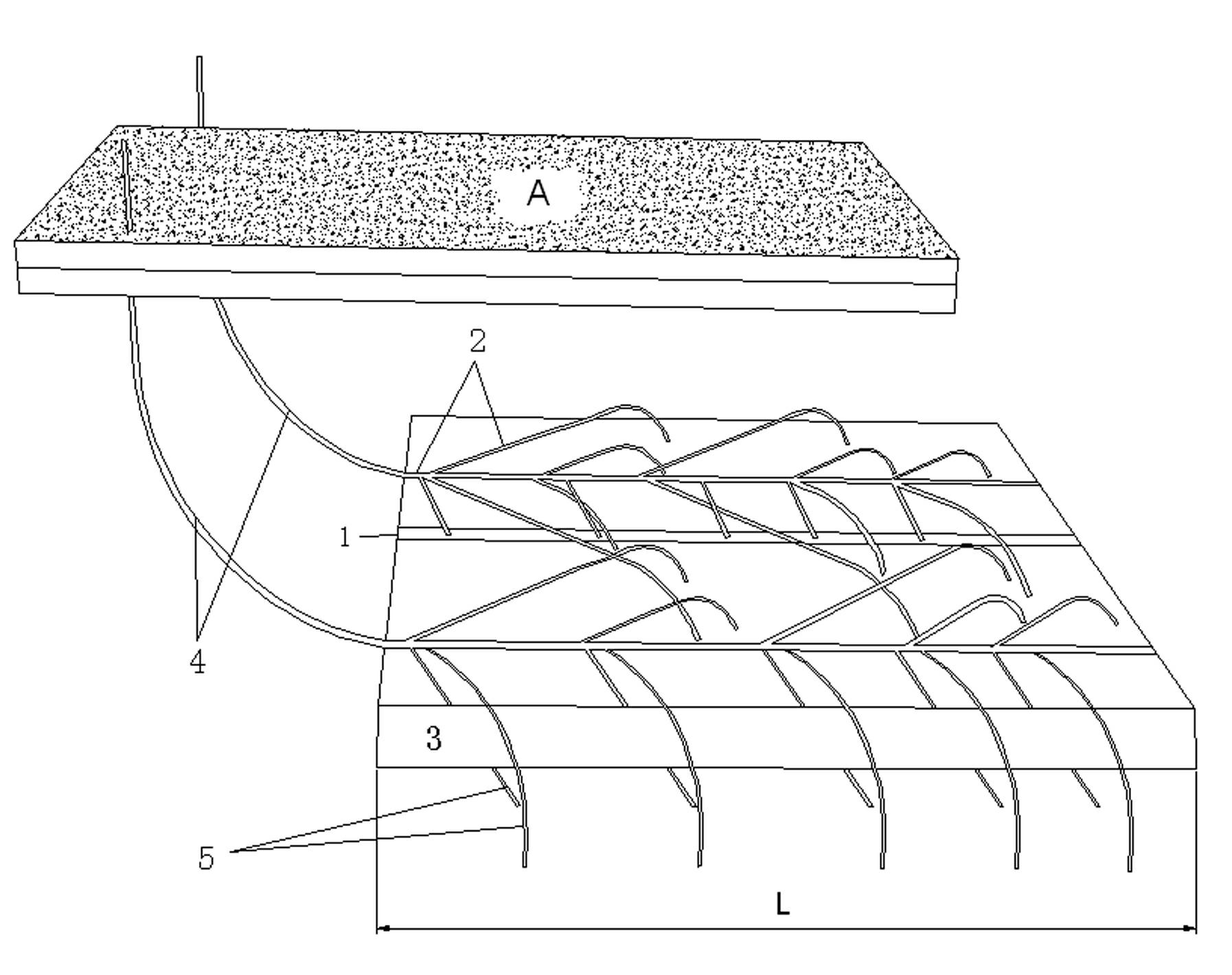

[0012] Example: such as figure 1 As shown, determine the position of the tail roadway 1 and the machine roadway 3 to be excavated in the working face, calculate the fracture zone layer through the coal thickness, goaf management, and roof and floor lithology, and select the right above the tail roadway 1 and the machine roadway 3 The fracture zone layer is used as the horizon of the main hole 2 of the horizontal well. The vertical well section, the deflection section 4 and the horizontal well section 2 are constructed on the ground, and then the lateral branch well 5 and the downward branch well 5 are constructed on the main hole 2 of the horizontal well. , and ensure that all the coal seams are drilled, and the lateral branch shaft 5 covers the entire working face, and the gas content in the tailgate 1, machine roadway 3 and working face range is reduced through ground drainage, replacing the traditional driving tailgate 1 and machine roadway 3 The special rock roadway for ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com