Safety sealing and air flow conveying method for fine coal gasification process

A technology of airflow conveying and coal gasification, which is applied to the gasification of granular/powdered fuels, the petroleum industry, and the manufacture of combustible gases. , increase the cost, the effect of high gas active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

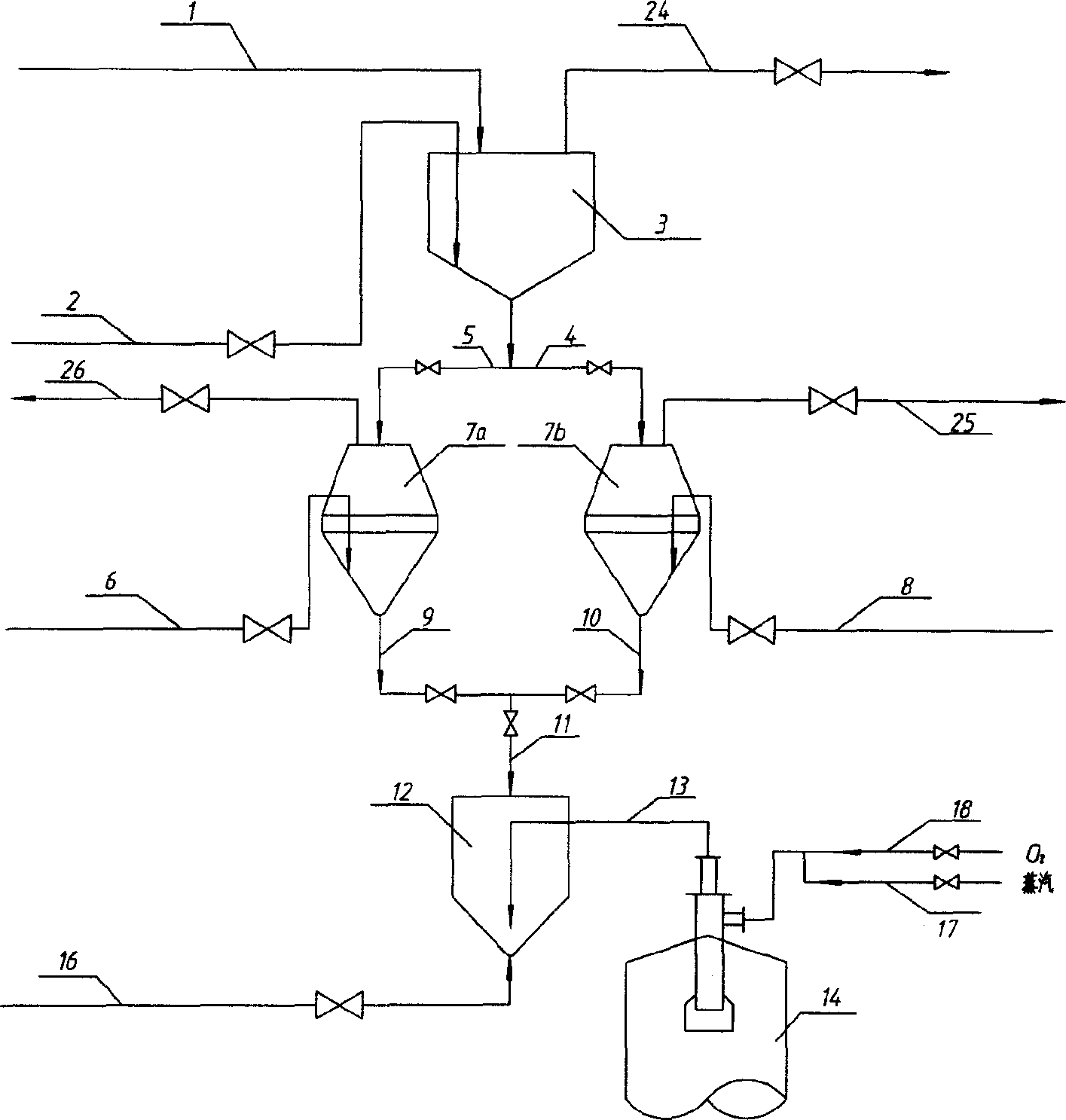

[0019] refer to figure 1 , the pulverized coal sent by the screw conveyor enters the pulverized coal storage bin 3 through the pipeline 1, and passes into the pulverized coal storage bin 3 through the pipeline 2. Gas (or flue gas with low oxygen content) to maintain its slightly positive pressure operation, and regularly remove part of the exhaust gas through the pipeline 24. Then, the pulverized coal enters into two alternately switched pulverized coal lockers 7a, 7b through the pipelines 4 and 5 respectively, and the pulverized coal is controlled to enter the pulverized coal feeding bin 12 through the pipeline 9 or through the pipeline 10 intermittently through the pipeline 11. Carbon dioxide gas with a pressure of 0.1-6.9MPa and a temperature of room temperature to 100°C is intermittently filled into the pulverized coal lock hopper through pipeline 6 or pipeline 8 to maintain its positive pressure operation, and at the same time intermittently and alternately through pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com