Nano catalyst of multi-corner-angle gradient structure and preparation method thereof

A nano-catalyst and gradient structure technology, applied in chemical instruments and methods, physical/chemical process catalysts, structural parts, etc., to achieve good electrochemical catalytic oxidation performance, simple preparation method, and improved roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

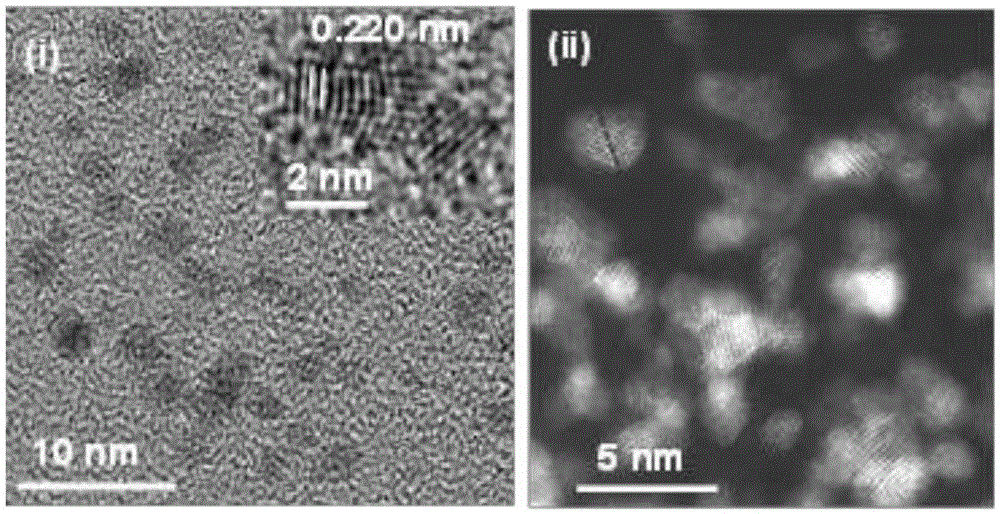

[0036] Below with (Fe-Pt)(Fe 1-x Pt x )O(OH) as an example to illustrate its preparation process and its electrochemical catalytic oxidation performance and CO poisoning resistance.

[0037] Step 1: configure salt solution, described salt solution is to use 0.28g (1.4mmol) FeCl 2 4H 2 O, 0.36g (0.7mmol) H 2 PtCl 6 ·6H 2 O, a solution formed by dissolving 0.53g (Mw=10000) of PVP in 50mL of N-methylpyrrolidone (NMP);

[0038] Step 2: configuring a reducing agent solution, the reducing agent solution is a colorless and transparent solution obtained by dissolving 0.35g (9.4mmol) NaBH in 50mL NMP;

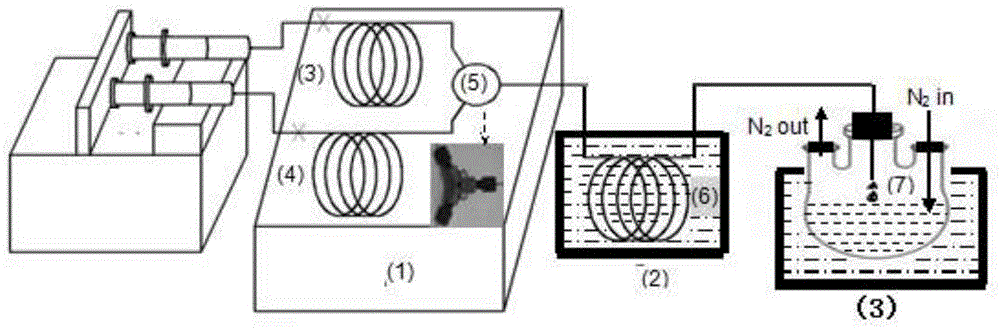

[0039] Step 3: Use a syringe to extract 40ml of the solution configured in step 1 and step 2 respectively, place it on the syringe pump, adjust the flow rate V to 5-10ml / min, and let the reactants react in the microfluidic reaction device, as shown in the figure ( 3) and (4) are preheating devices to preheat the reducing agent and salt solution, and the preheated reducing agent a...

Embodiment 2

[0044] Step 1: configure salt solution, described salt solution is to use 0.28g (1.4mmol) FeCl 2 4H 2 O, 0.36g (0.7mmol) H 2 PtCl 6 ·6H 2 O, the solution that 0.53g (Mw=10000) PVP is dissolved in 50mLNMP forms;

[0045] Step 2: configure the reducing agent solution, the reducing agent solution is 0.35g (9.4mmol) NaBH 4 A colorless transparent solution obtained by dissolving in 50mL NMP;

[0046] Step 3: Use a syringe to draw 40ml of the solution prepared in Step 1 and Step 2 respectively, and place it on the syringe pump, and adjust the flow rate V to 5-10ml / min. The reducing agent and salt solution are preheated, and the preheated reducing agent and salt solution are mixed in the Y-shaped mixer at (5) to complete the process of nucleation-growth-termination, and in the figure (7) Collect the product. The preheating temperature is set to 120°C, the temperature of the thermostat 2 is set to 30°C, and the receiving temperature is set to 0°C;

[0047] Step 4: centrifuge t...

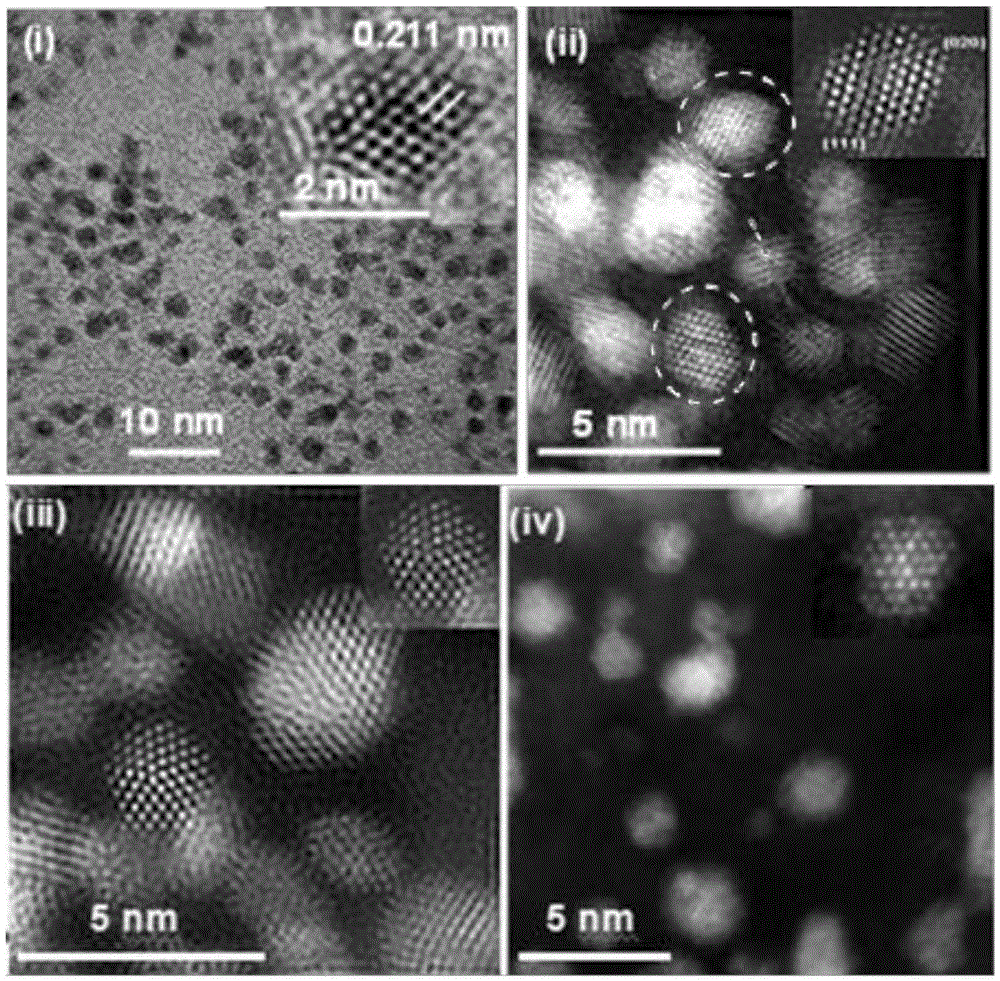

Embodiment 3

[0051] Step 1: configure salt solution, described salt solution is to use 0.28g (1.4mmol) FeCl 2 4H 2 O, 0.36g (0.7mmol) H 2 PtCl 6 ·6H 2 O, the solution that 0.53g (Mw=10000) PVP is dissolved in 50mLNMP forms;

[0052] Step 2: configure the reducing agent solution, the reducing agent solution is 0.35g (9.4mmol) NaBH 4 A colorless transparent solution obtained by dissolving in 50mL NMP;

[0053] Step 3: Use a syringe to draw 40ml of the solution prepared in Step 1 and Step 2 respectively, and place it on the syringe pump, and adjust the flow rate V to 5-10ml / min. The reducing agent and salt solution are preheated, and the preheated reducing agent and salt solution are mixed in the Y-shaped mixer at (5) to complete the process of nucleation-growth-termination, and in the figure (7) Collect the product, and dissolve the carbon black with 4 times the mass of the metal salt content in 10ml NMP and place it in the receiving device, so that the product obtained above is direct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com