Solar-driven coal gasification methanol synthesis and zero-emission power generation combined system

A technology for methanol synthesis and solar energy, which is used in the purification of combustible gas, the production of bulk chemicals, the preparation of hydroxyl compounds, etc., to achieve the effect of improving conversion rate, improving energy utilization efficiency, and realizing clean utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

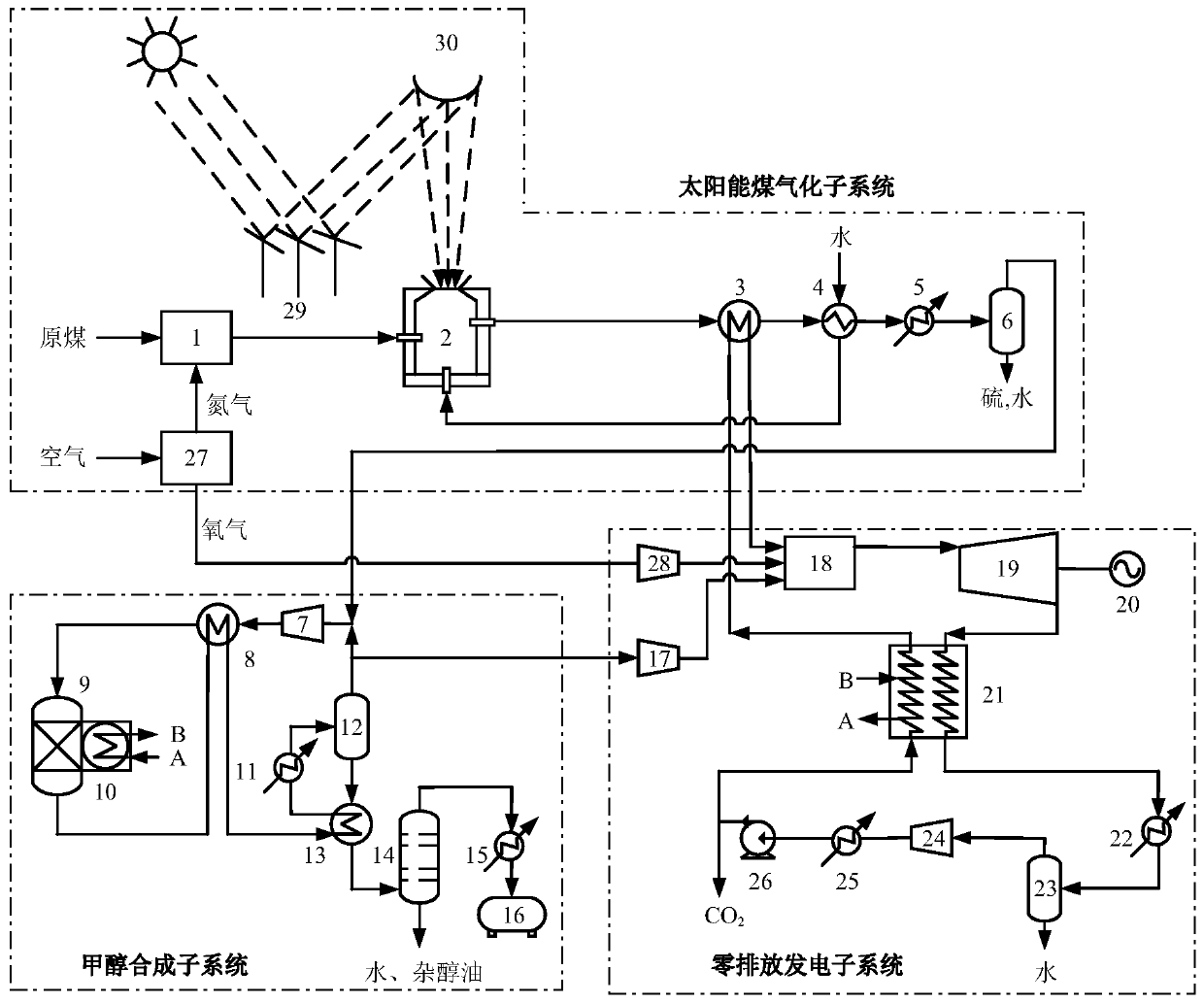

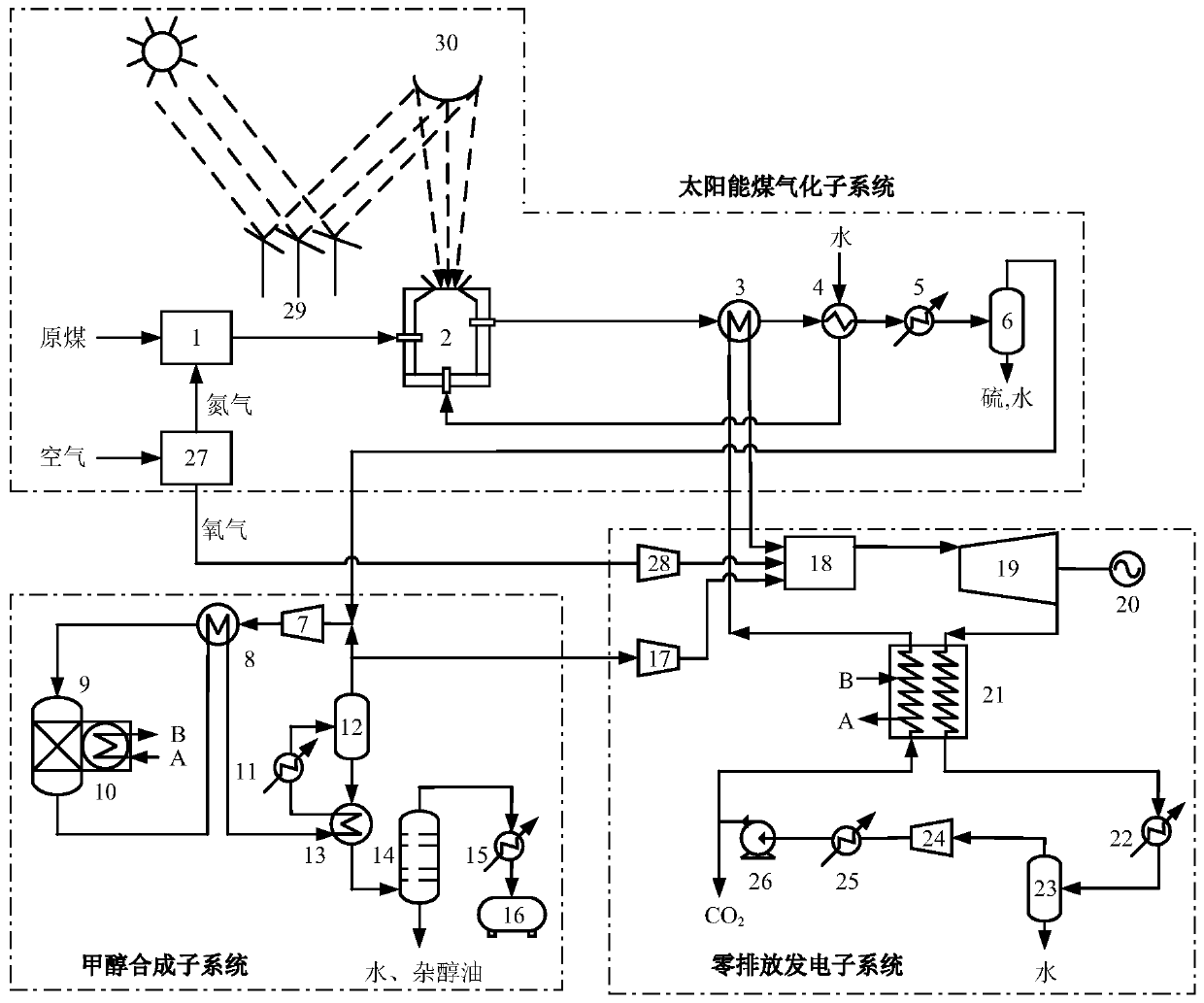

[0026] The present invention proposes a solar-driven coal gasification methanol synthesis and zero-emission power generation cogeneration system, which will be described below in conjunction with the accompanying drawings.

[0027] Such as figure 1 The shown solar-driven coal gasification methanol synthesis and zero-emission power generation cogeneration system includes three subsystems such as solar coal gasification, methanol synthesis, and zero-emission power generation; wherein, the solar coal gasification subsystem consists of a pre-drying device 1 and solar gas Gasification furnace 2, carbon dioxide heater 3, steam generator 4, syngas cooler 5 and purification and separation device 6 are connected in series; steam generator 4 is connected to solar gasification furnace 2; air separation unit 27 is connected to pre-drying device 1; The heliostat 29 projects onto the reflection tower 30, and then concentrates the light onto the solar gasification furnace 2 to form a solar c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com