Method for processing fly ash

A treatment method, fly ash technology, applied in the field of acid-base combined method, can solve problems such as difficult to produce economic benefits, low resource utilization rate, secondary pollution, etc., and achieve high added value of products, no three waste pollution, and low technical risk Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

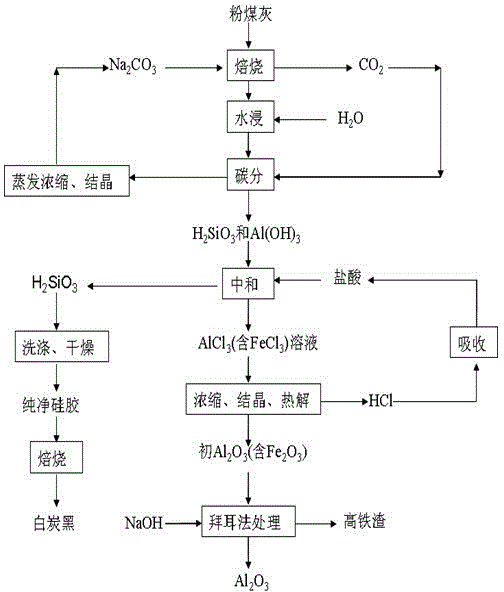

Method used

Image

Examples

Embodiment 1

[0036] 1) Grind the high-alumina fly ash of a circulating fluidized bed in a certain place (see Table 1 for the chemical composition) to 200 mesh, and mix the ground fly ash and sodium carbonate by weight percentage fly ash: sodium carbonate = 1:2 Proportions were mixed and fired at 800°C for 1 hour. The sintered product is leached with water (the weight percentage of the sintered product and water is 1:100, and the water is ordinary tap water) at 80°C for 3 hours and then filtered, and the leaching solution is carbon dioxide at 90°C for 3 hours and then filtered to obtain Silica gel and aluminum hydroxide, and the filtrate is sodium carbonate solution, which is returned to the process for recycling after evaporation and concentration.

[0037]2) Neutralize the silica gel and aluminum hydroxide obtained in step (1) with 36% hydrochloric acid (5 tons of hydrochloric acid per ton of silica gel and aluminum hydroxide) at 80°C for 1 hour, then filter to obtain silica gel, and wash...

Embodiment 2

[0041] 1) Grind the high-alumina fly ash of a circulating fluidized bed in a certain place whose chemical composition is shown in Table 1 to 400 mesh, and mix the ground fly ash and sodium carbonate by weight percentage fly ash: sodium carbonate = 1:3 The ratio was mixed and baked at 1000°C for 3 hours. The sintered product is leached with water (the weight percentage of sintered product and water is 1:150, and the water is ordinary tap water) at 100°C for 5 hours and then filtered, and the leaching solution is carbon dioxide at 90°C for 5 hours and then filtered to obtain Silica gel and aluminum hydroxide, and the filtrate is sodium carbonate solution, which is returned to the process for recycling after evaporation and concentration.

[0042] 2) Neutralize the silica gel and aluminum hydroxide obtained in step 1) with 36% hydrochloric acid (6 tons of hydrochloric acid per ton of silica gel and aluminum hydroxide) at 100°C for 2 hours and then filter to obtain silica gel. Aft...

Embodiment 3

[0047] 1) Grind the high-aluminum fly ash (see Table 2 for the chemical composition) of a pulverized coal furnace in a certain place to 300 mesh, and mix the ground fly ash and sodium carbonate in a ratio of fly ash: sodium carbonate = 1:1 by weight Mixing was carried out and firing was carried out at 500° C. for 0.5 hours. The sintered product is leached with water (the weight percentage of sintered product and water is 1:50, and the water is ordinary tap water) at 60°C for 1 hour and then filtered, and the leaching solution is carbon dioxide at 80°C for 1 hour and then filtered to obtain Silica gel and aluminum hydroxide, and the filtrate is sodium carbonate solution, which is returned to the process for recycling after evaporation and concentration.

[0048] 2) Neutralize the silica gel and aluminum hydroxide obtained in step 1) with 25% hydrochloric acid (4 tons of hydrochloric acid per ton of silica gel and aluminum hydroxide) at 50°C for 0.5 hours and then filter to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com