Method for extracting ACE (Angiotensin Converting Enzyme) inhibitory peptide from urechis unicinctus and application

A single-ring thorn and inhibitory peptide technology, which is applied in the field of comprehensive utilization of biological resources, can solve problems such as separation and purification of active peptides, and achieves the effects of easy mass production, good activity and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Preparation of Monocyclic Cysts autolysase

[0027] 1.1 Preparation of the crude enzyme solution of monocyclic thorn autolyase:

[0028] (1) Take the discarded viscera of the single-ringed thorn and thaw at room temperature, which is stored in a freezer at -20--10 °C, and then wash it with sterile water to remove impurities after it is completely thawed. Add PBS (0.1 mol / l, pH 8.0) for homogenization, place at 4 °C overnight, centrifuge at 5000 r / min for 8 min, and collect the supernatant;

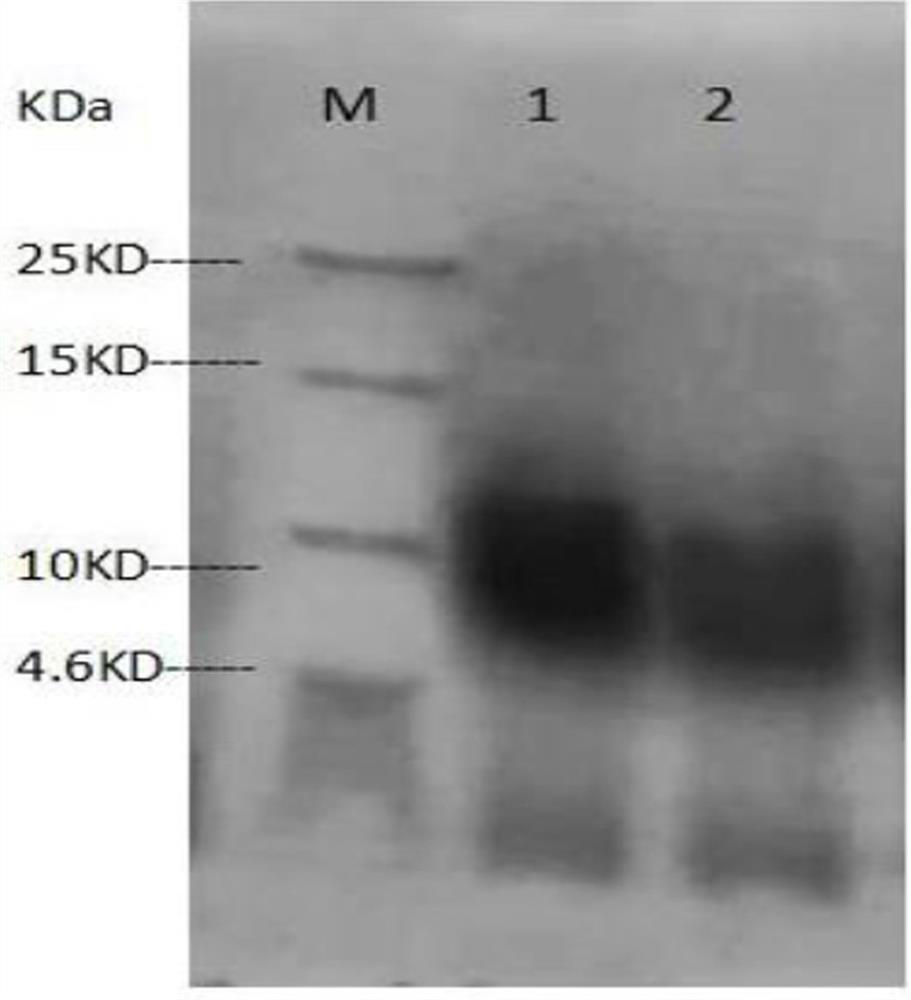

[0029] (2) Add ammonium sulfate to the above collected supernatant to 20% saturation, place at 4°C for 4 hours; centrifuge at 8000 r / min for 10 minutes, collect the supernatant, and add ammonium sulfate to the supernatant to 70% Saturation, placed at 4 °C for 4 h; centrifuged at 8000 r / min for 10 min, took the precipitate, added 10 times its volume of PBS buffer to the precipitate, and dialyzed with a dialysis bag with a molecular weight cut-off of 8KD-14KD to obtain aut...

Embodiment 2

[0035] Example 2: Screening of ACE-inhibited peptidolysis target protease

[0036] 2.1 Pretreatment of raw materials: Weigh 1kg of the frozen product of the single-ringed thorn beetle, thaw at 20°C for 3 hours, and then add 5 times the volume of the treatment solution to soak for 30min. The treatment solution consists of 4.5g of sodium chloride, chloramphenicol 0.25g, penicillin 0.25g, EDTA·2Na 0.25g, sterile water 4.09475kg. Homogenize.

[0037] 2.2 Centrifugation of raw materials: add 2% of its mass of enzyme to the homogenate, enzymolysis under optimum conditions, inactivate the enzyme at 100 °C for 15 min; after enzymatic hydrolysis, cool down to 20 °C, centrifuge at 8000 r / min for 20 min, and collect the supernatant by filtration .

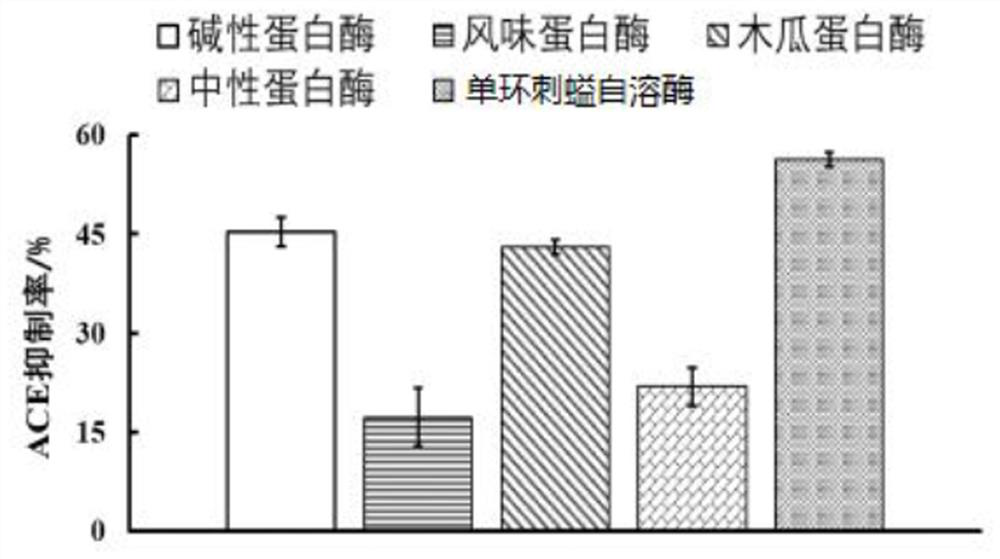

[0038] 2.3 Screening of protease: 5 kinds of proteases were added in the slurries respectively, and the ratio of material to liquid was 1:2, wherein, 2% autolysate of monocyclic thorn, pH 7.5, 2% Bacillus licheniformis protease, pH 7.0; 2% ...

Embodiment 3

[0050] Example 3: Optimization of ACE-inhibiting peptide enzymatic hydrolysis process.

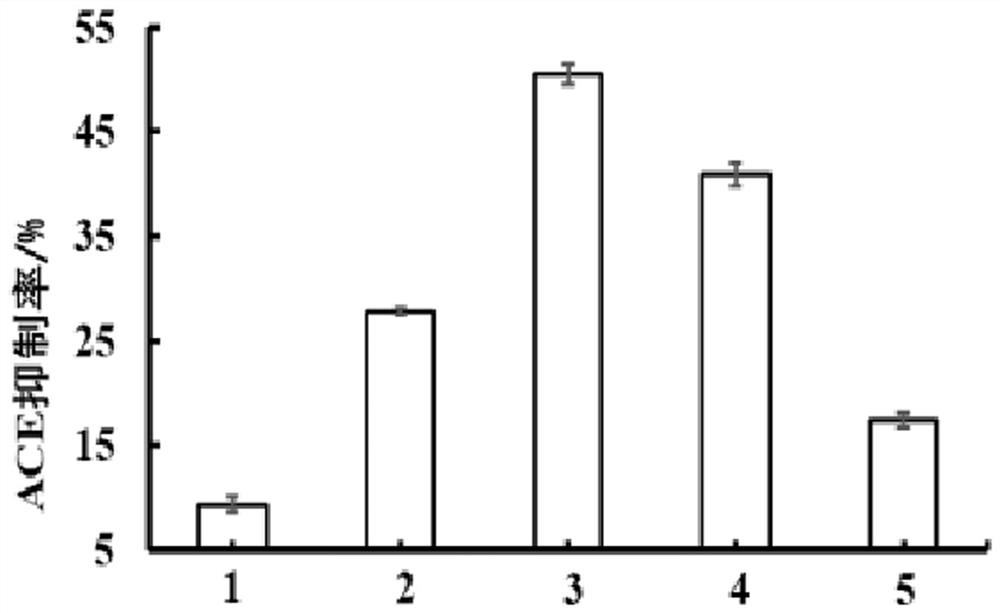

[0051] Single factor and response surface process optimization was carried out according to the single-ringed thorn autolysase selected in Example 2.

[0052] 3.1 Pretreatment of raw materials: Weigh 1kg of the frozen product of the single-ringed thorn beetle, thaw at 20°C for 3 hours, and then add 5 times the volume of the treatment solution to soak for 30 minutes. The treatment solution consists of 4.5g of sodium chloride, chloramphenicol 0.25g, penicillin 0.25g, EDTA·2Na 0.25g, sterile water 4.09475kg. Homogenize.

[0053] 3.2 Centrifugation of raw materials: add 2% of its mass enzyme to the homogenate, enzymolysis under optimal conditions, inactivate the enzyme at 100 °C for 15 min; after enzymatic hydrolysis, cool to 20 °C, centrifuge at 8000 r / min for 20 min, and filter to collect the supernatant .

[0054] 3.3 Single factor experiment: determine the ratio of solid to liquid (1:1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com