Trona sodium bicarbonate mother liquor resource utilization system and treatment method thereof

A baking soda and trona technology, which is applied in the resources utilization system of trona mother liquor and its treatment field, can solve the problems of reduced output, lower trona grade, pollution, etc., and achieve easy operation, simple process and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

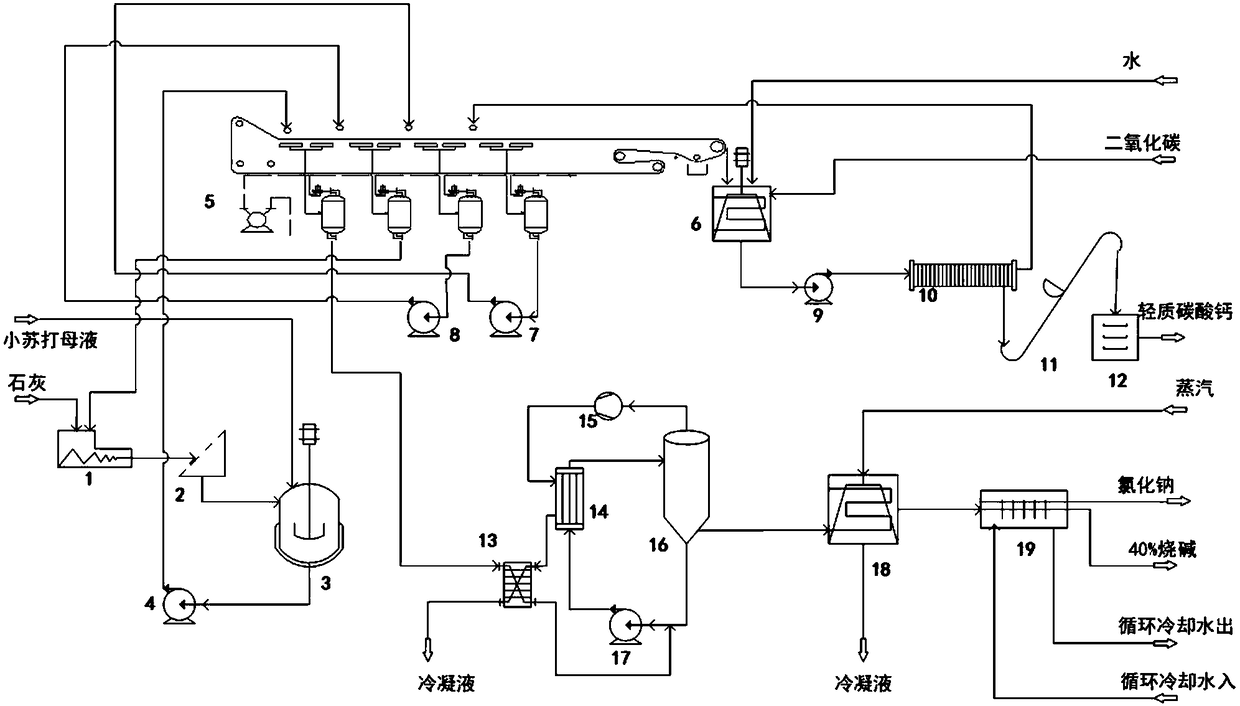

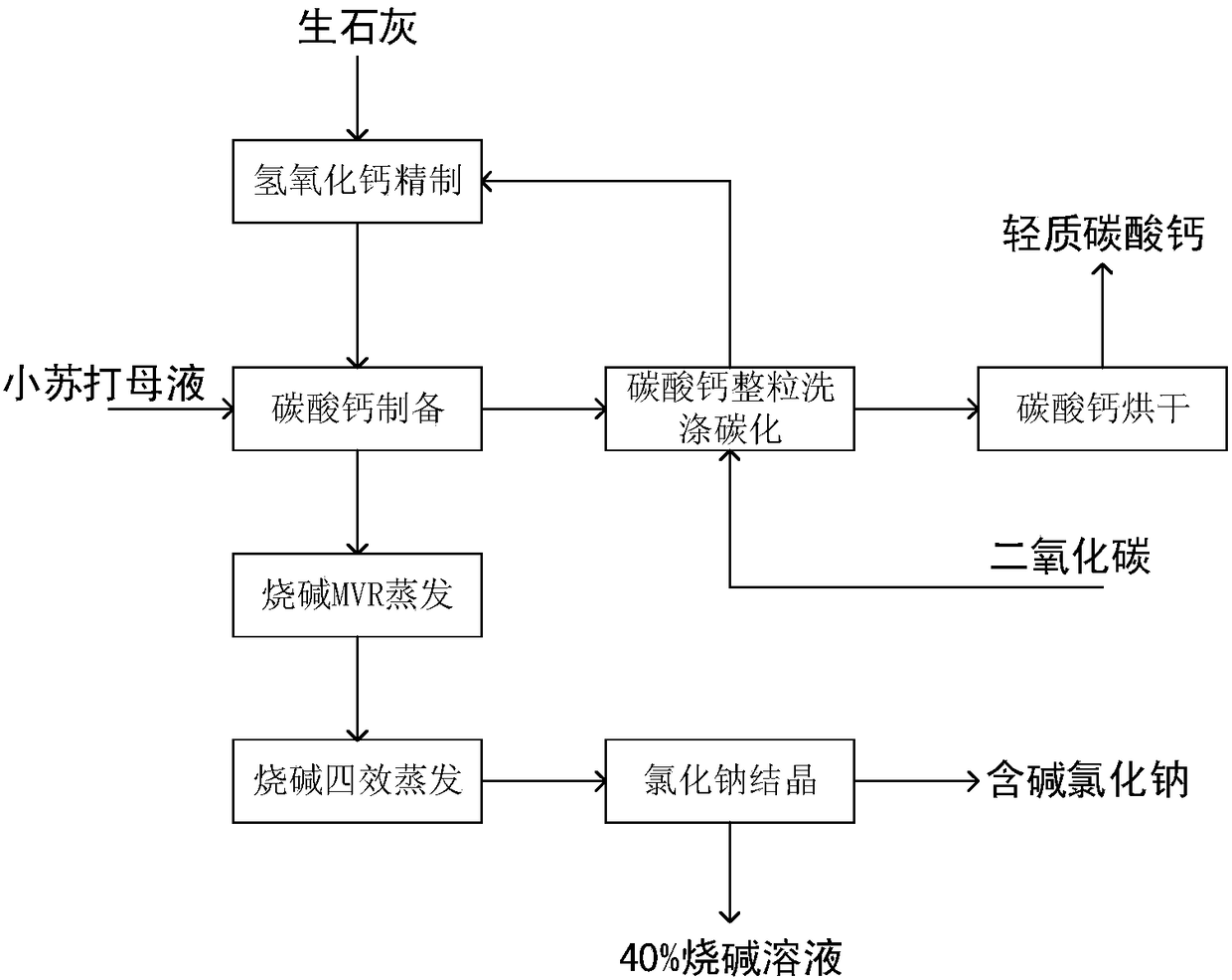

[0118] A resource utilization system of trona baking soda mother liquor, the schematic diagram of the system is as follows figure 1 As shown, the system includes a lime digestion unit, a causticizing reaction unit, a slurry separation unit, a calcium carbonate whole particle carbonation unit, a calcium carbonate separation and drying unit, a caustic soda evaporation unit and a crystallization separation unit.

[0119] The lime digestion unit comprises a quicklime digester 1 and a milk of lime vibrating screen 2, the inlet of the quicklime digester 1 is connected with the quicklime feed pipeline, and the outlet of the quicklime digester 1 is connected with the inlet of the milk of lime vibrating screen 2 , the outlet of the lime milk vibrating screen 2 is connected with the causticizing reaction unit.

[0120] The causticizing reaction unit includes a causticizer 3, the inlet of the causticizer 3 is connected to the outlet of the lime milk vibrating screen 2, the outlet of the ...

Embodiment 2

[0136] The resource utilization system of the trona baking soda mother liquor of this implementation is the same as that of Example 1.

[0137] The treatment method of the trona baking soda mother liquor resource utilization system provided in this embodiment is:

[0138] (1) First add 48Kg of quicklime with a mass percentage of 93wt% into the quicklime digester, add 145Kg of primary washing liquid, digest for 1.8h, then pass the digested material through a lime milk vibrating sieve to remove undigested impurities and obtain pure milk of lime;

[0139] (2) Add trona baking soda mother liquor 1m in the causticizer 3 , where NaHCO 3 The mass concentration is 50g / L, Na 2 CO 3 The mass concentration is 25g / L, and the NaCl mass concentration is 75g / L; the milk of lime is slowly added into the causticizer and stirred under stirring, and the causticizing reaction occurs, and the causticizing temperature is 50°C;

[0140] (3) The material after causticization is subjected to thre...

Embodiment 3

[0145] The resource utilization system of the trona baking soda mother liquor of this implementation is the same as that of Example 1.

[0146] The treatment method of the trona baking soda mother liquor resource utilization system provided in this embodiment is:

[0147] (1) First add 50Kg of quicklime with a mass percentage of 95wt% into the quicklime digester, add 150Kg of primary washing liquid, digest for 2 hours, then pass the digested material through a lime milk vibrating screen to remove undigested impurities and obtain pure lime milk;

[0148] (2) Add trona baking soda mother liquor 1m in the causticizer 3 , where NaHCO 3 The mass concentration is 60g / L, Na 2 CO 3 The mass concentration is 30g / L, and the NaCl mass concentration is 90g / L; the milk of lime is slowly added into the causticizer and stirred under stirring, and the causticizing reaction occurs, and the causticizing temperature is 60°C;

[0149] (3) The material after causticization is subjected to thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com