Diffused gas utilizing system and method

A technology for releasing gas and air, applied in combustion methods, gas fuel burners, manufacturing converters, etc., can solve problems such as unreasonable ignition and release, waste of fuel, loss of carbon enrichment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

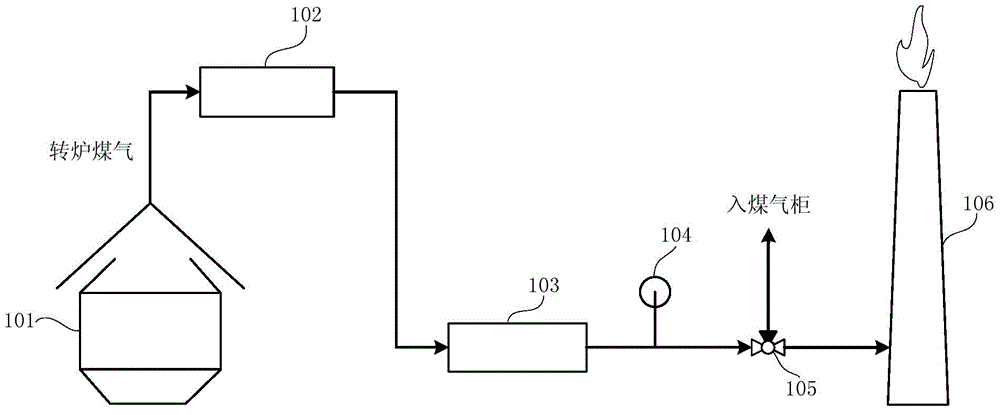

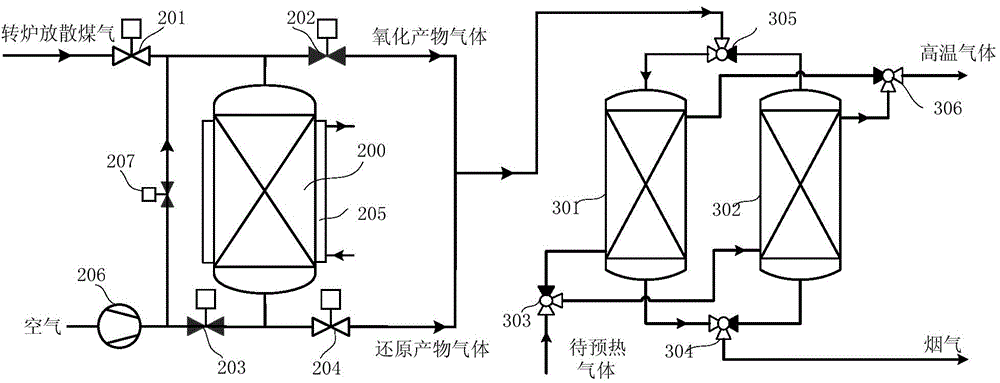

[0046] Taking the converter gas release as an example, the present invention will be further described in detail in conjunction with the accompanying drawings and embodiments. Other forms of release gas or combustion tail gas can replace the converter gas release in the following embodiments.

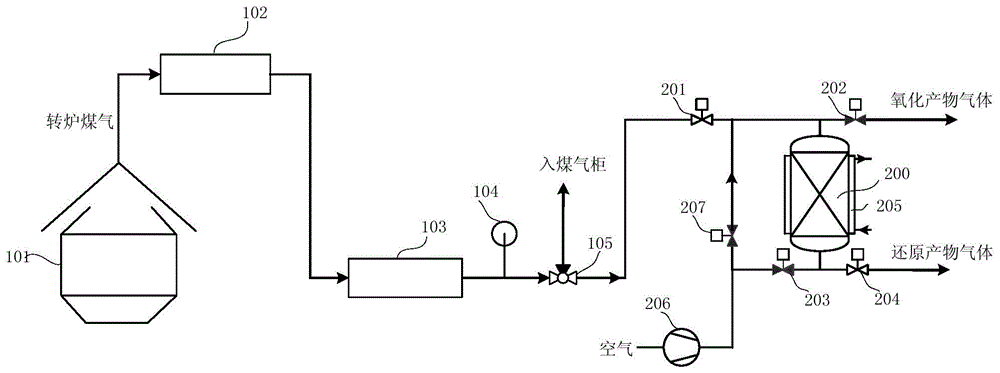

[0047] like figure 2 Shown is a schematic diagram of a converter gas utilization system provided by an embodiment of the present invention. According to the utilization system of the converter gas released by the present invention, it is connected to the release side of the three-way valve 105 to process and utilize the converter gas that was originally directly ignited and released. The system for utilizing the blown gas from the converter includes a chemical looping combustion reactor 200, and the chemical looping combustion reactor is filled with an oxygen carrier. The chemical looping combustion reactor is connected with a first input pipeline, a first output pipeline, a second in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com