Method for preparing methane-rich gas by utilizing wastes

A waste and methane-enriched technology, which is applied in the direction of gas fuel, special carbonization, petroleum industry, etc., can solve the problem that waste semi-coke has no application market, etc., and achieve the effect of convenient subsequent utilization, mild preparation conditions and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

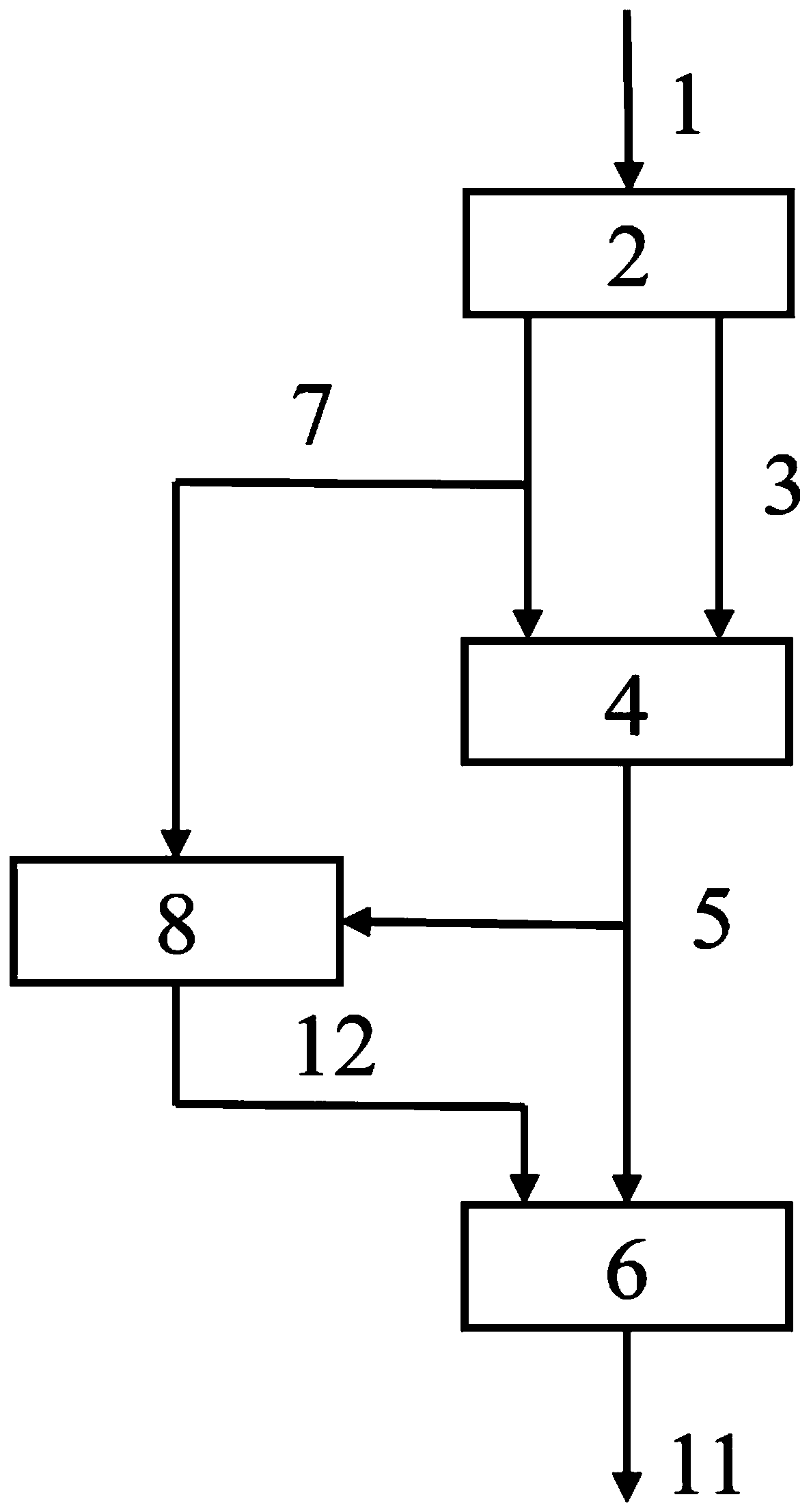

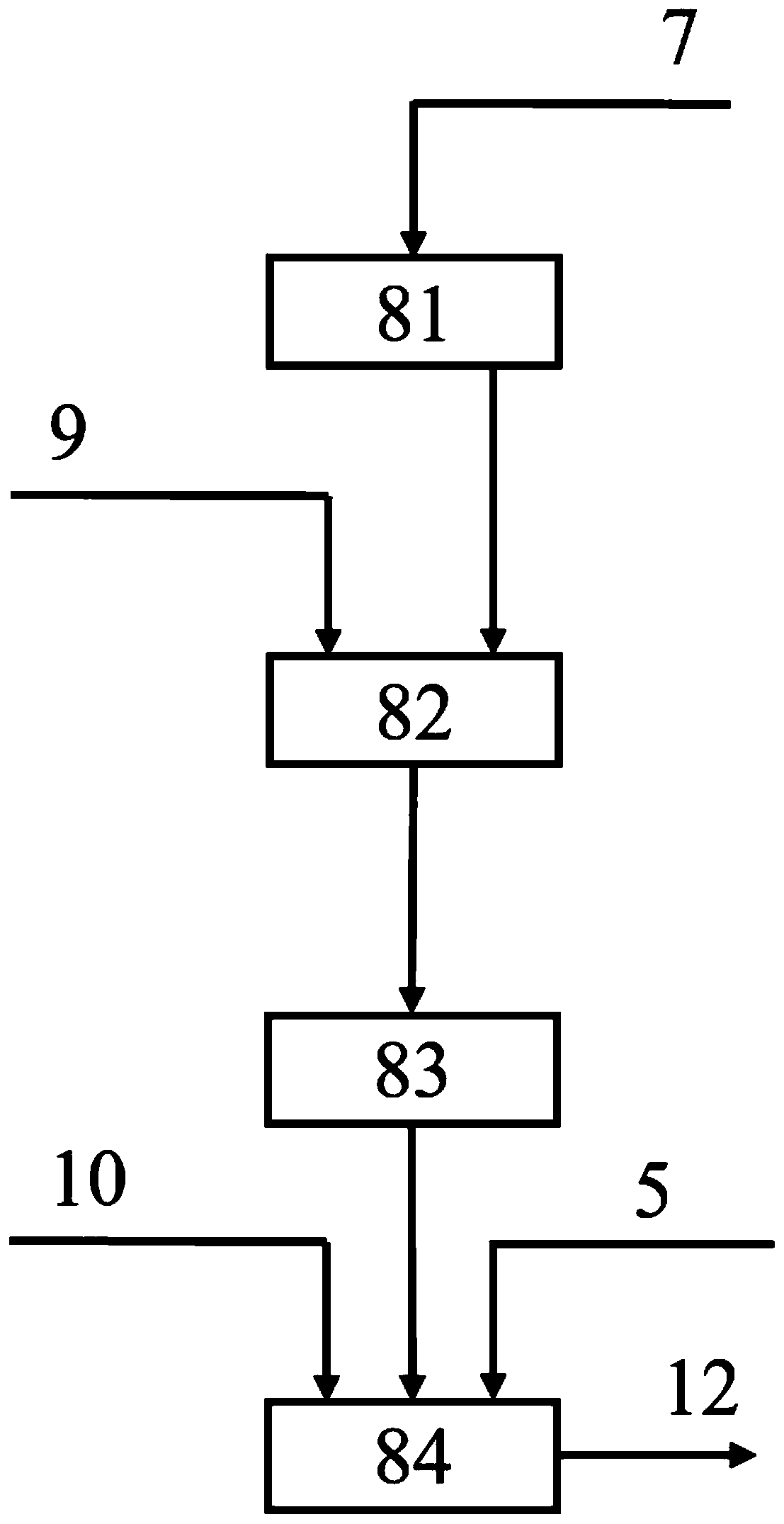

[0045] Such as figure 2 As shown, in the present invention, the preparation method of catalyst 12 specifically includes the following sub-steps:

[0046] Step 2-1, place semi-coke 7 in the saline solution containing active component 81 for full impregnation, in the present invention, before impregnating the saline solution with active component, semi-coke is first ground; then filtered; A small amount of chitosan or flour 9 is added as a binding agent and molded in a molding machine 82 to obtain semi-coke-based catalyst particles.

[0047] In the present invention, the molding machine 82 may be selected from an extrusion molding machine, a disc granulator, and the like.

[0048] In the present invention, the salt solution is one of nitrate saturated solution, nitrite saturated solution, sulfate solution, carbonate solution, basic carbonate solution and acetate solution; and perform molding operation, preferably , so that the particle size of the shaped particles is 4-60 mes...

Embodiment 1

[0060] In step 1, 50 t / d of domestic waste oversize with a moisture content of 42% is placed in a rotary kiln reactor, and continuously pyrolyzed at 700° C. to obtain semi-coke 7 and volatile components 3 .

[0061] Step 2, catalytic reforming of volatiles 3 with 75% semi-coke 7 in reforming reactor 4 to obtain hydrogen-rich and CO / CO 2 Syngas 5 whose composition is H2 :60%, CO: 25%, CO 2 : 13%, other ingredients 2%, also contains tar and a small amount of C 2 、C 3 At the same time, 25% of the mass of semi-coke 7 is used to remove stones and other sundries through sieving, grind to a particle size of about 150 mesh, and then impregnate a saturated solution of nickel nitrate. The active component 81 is nickel, then filter, and then add A small amount of chitosan 9 is kneaded and extruded in a molding machine 82 to make particles with a particle size of 4 to 10 meshes, then dried in a reactor 83, fed with nitrogen and roasted to 500 ° C for a period of time, and then It is th...

Embodiment 2

[0065] In step 1, 50 t / d of sewage sludge with a water content of 22% is placed in a rotary kiln reactor and continuously pyrolyzed at 550° C. to obtain semi-coke 7 and volatile components 3 .

[0066] Step 2, catalytic reforming of volatiles 3 with 70% semi-coke 7 in reforming reactor 4 to obtain hydrogen-rich and CO / CO 2 of syngas whose composition is H 2 :62%, CO: 20%, CO 2 : 15%, other ingredients 3%, also contains tar and a small amount of C 2 、C 3 At the same time, use 30% of the quality of semi-coke 7 to remove stones and other sundries through sieving, grind to 200 mesh, send it into a saturated solution of cobalt nitrate for impregnation, the active component 81 is cobalt, then filter, and then add a small amount of Chitosan and lanthanum oxide with 0.5% semi-coke mass are kneaded and extruded in a molding machine 82 to make particles with a particle size of 5 to 8 meshes, then first dried in a reactor 83, and then fed with nitrogen to raise the temperature to 400 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com