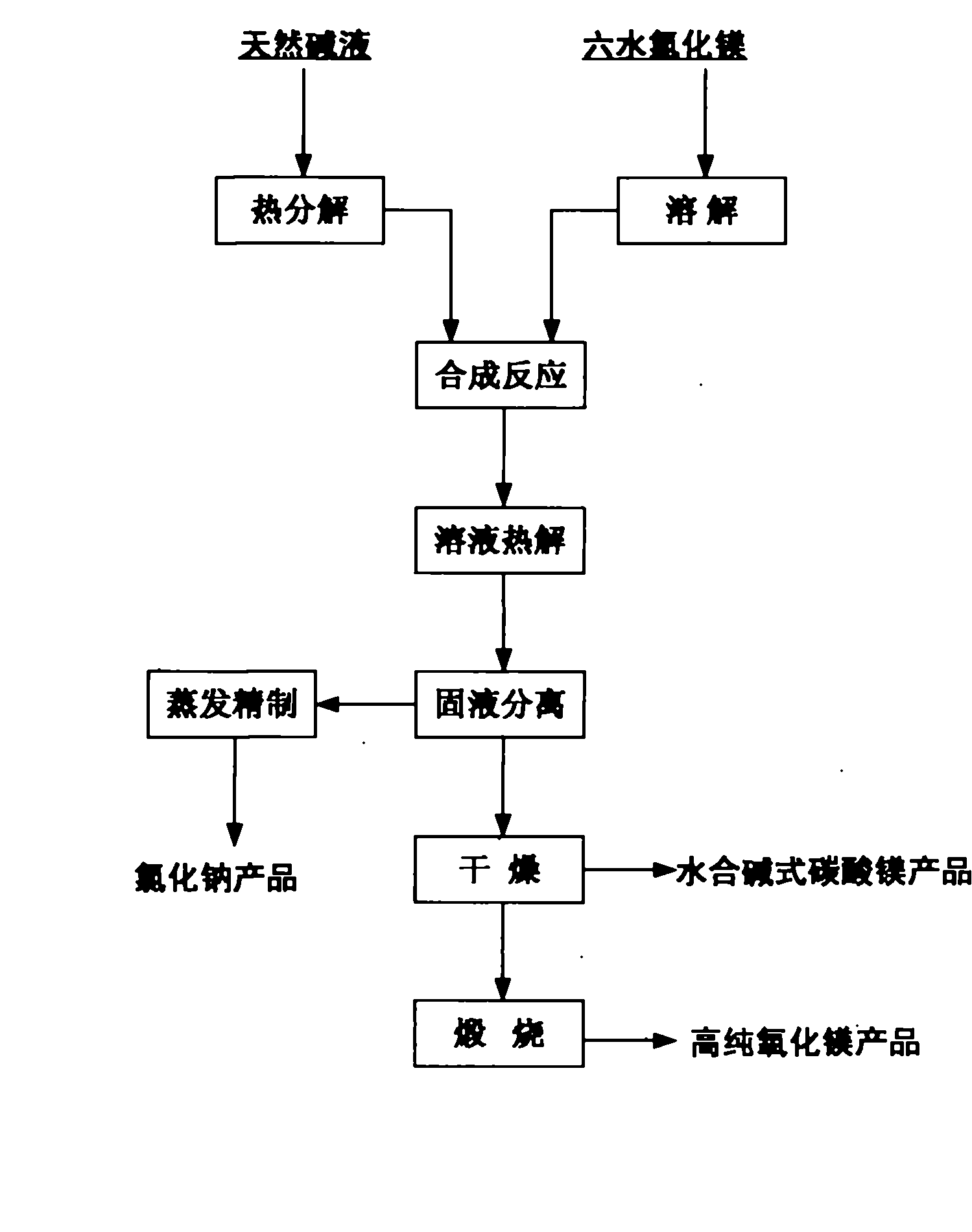

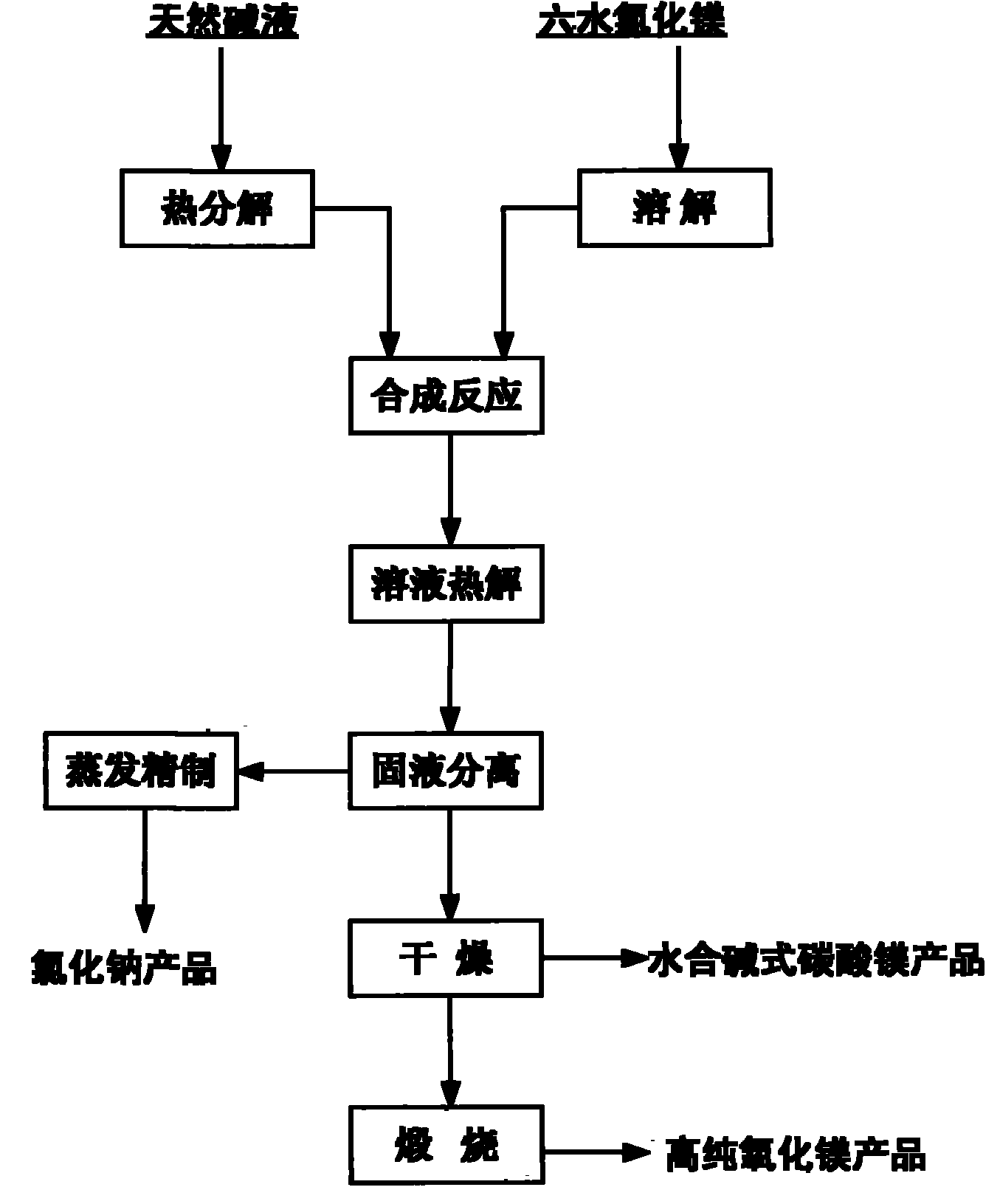

Method for preparing basic magnesium carbonate and high purity magnesium oxide with trona

A trona and magnesium carbonate technology, applied in the direction of magnesium carbonate, magnesium oxide, etc., can solve the problems of weak alkalinity, low conversion rate of magnesium oxide, harsh operating environment, etc., and achieve low impurity content, low mining cost, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049] Weigh 400kg MgCl 2 ·6H 2Add O into the stirring tank, put it into 800L hot water at 60°C, stir fully, then add the magnesium chloride solution into the sand filter, filter the solid particles in it, add it into the 3000L enamel reaction kettle, and heat to 80℃~105℃. The natural lye is decomposed by thermal decomposition at 80-110°C in a thermal decomposition tower, wherein the temperature at the bottom of the tower is 130°C, the temperature at the top of the tower is 100°C, the total alkali of the solution after reaction is above 180g / L, and the content of sodium bicarbonate is 50g / L, into the metering tank, which takes a volume of 1000L, puts it into the reaction kettle, heats the solution, boils, pyrolyzes the magnesium bicarbonate in it to generate magnesium carbonate, keeps the temperature, and the total reaction time is 1 to 2 hours , and then enter the box filter to filter, and then use 40-60 times the amount of solids to wash water at a temperature of 60-80°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com