Electro-conductive glass substrate cleaning agent and preparation method thereof

A technology of conductive glass and cleaning agent, which is applied in the directions of detergent compounding agent, detergent composition, chemical instrument and method, etc., can solve the problems of high energy consumption, equipment corrosion, high price, etc., and achieves low energy consumption and processing operation. Simple and clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

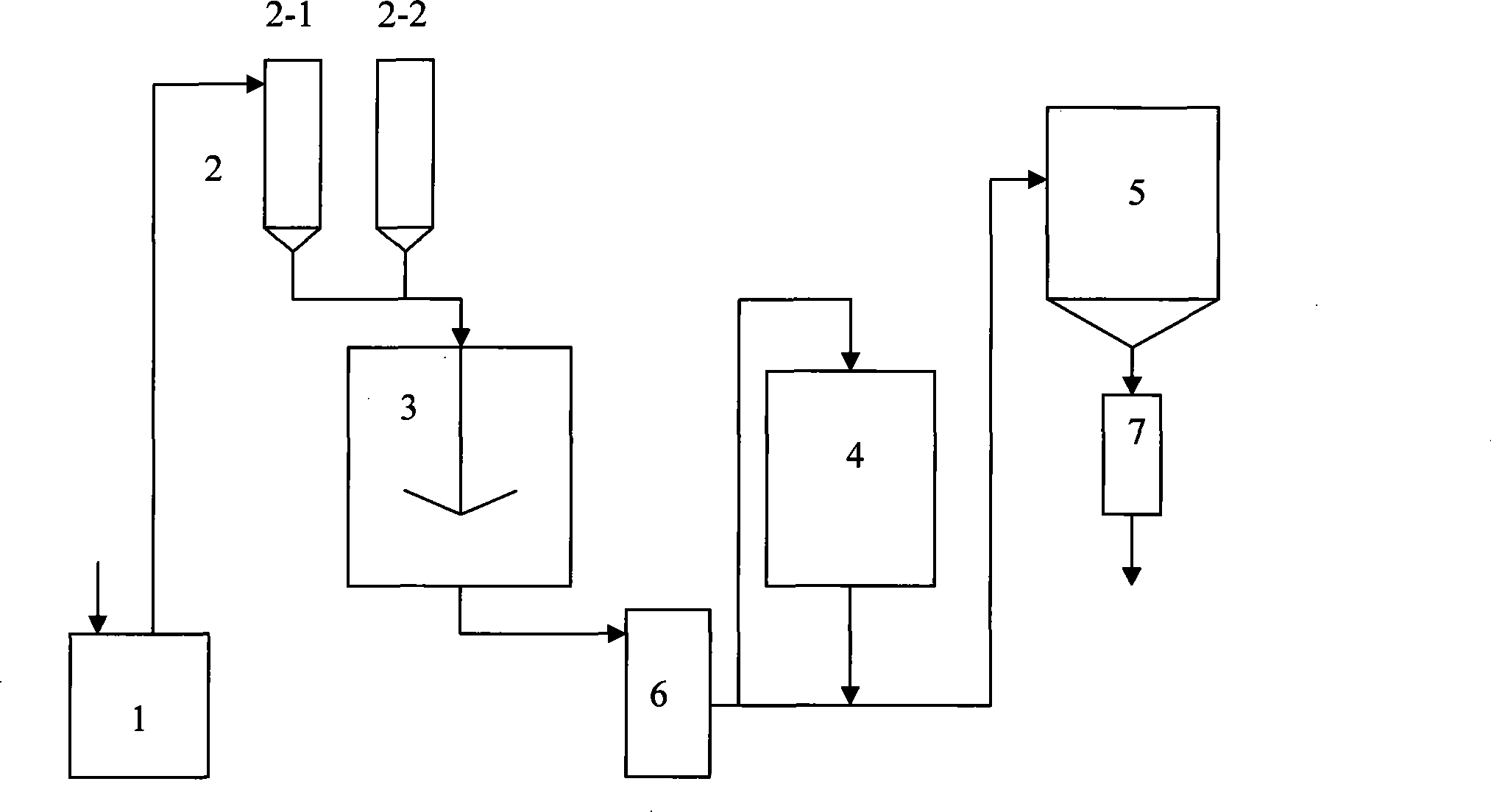

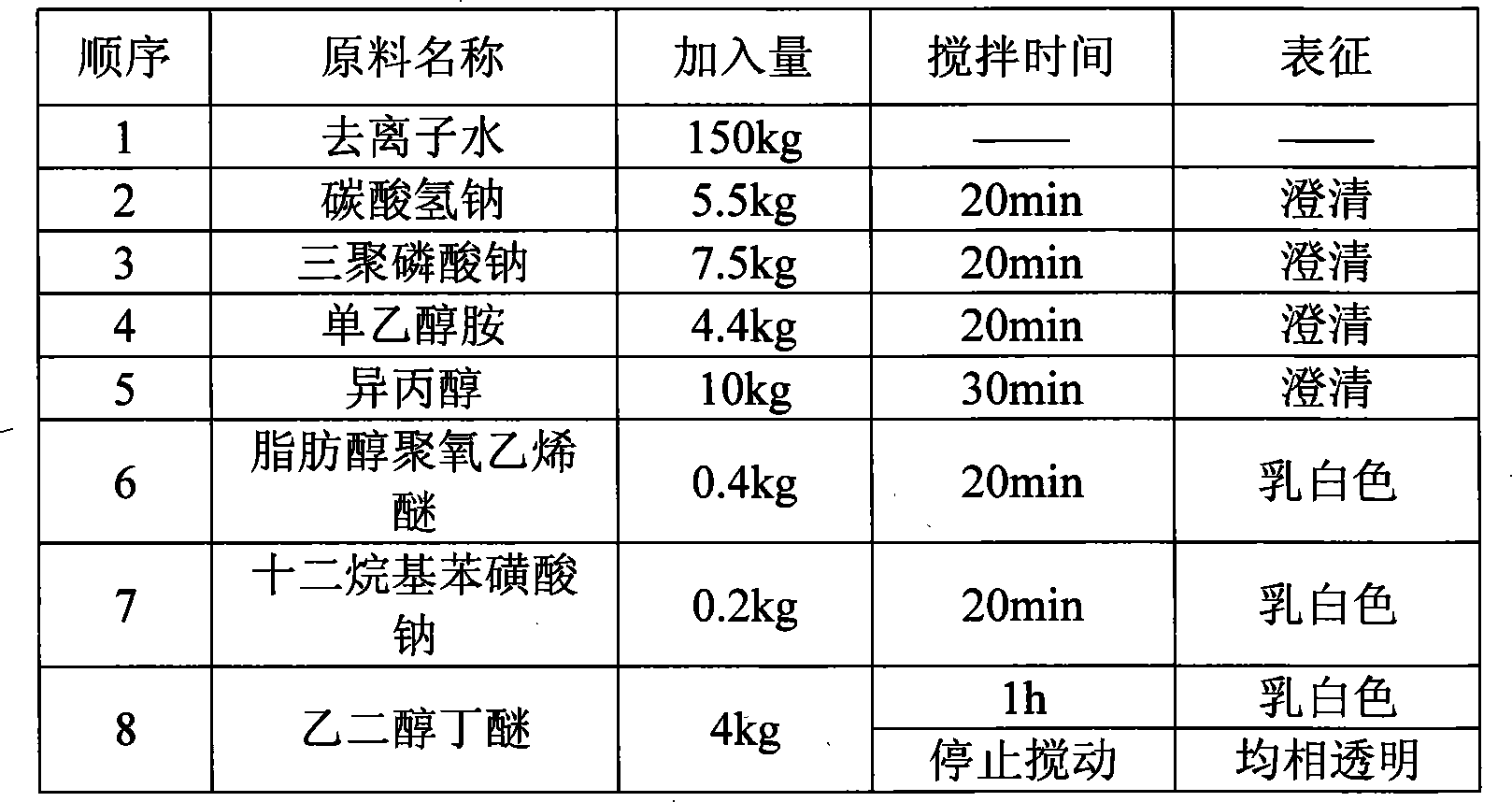

[0019] Add deionized water into the emulsification tank, then add sodium bicarbonate and sodium tripolyphosphate, stir until the solution is clear and transparent, take the monoethanolamine in the metering tank 2-1 and add it into the emulsification tank, and stir; take the monoethanolamine in the metering tank 2-2 Add isopropanol to the emulsification tank and stir; take the fatty alcohol polyoxyethylene ether in the metering tank 2-3 and add it to the emulsification tank and stir; add sodium dodecylbenzenesulfonate to the emulsification tank and stir; then take the metering tank 2-3 Add the ethylene glycol butyl ether in 4 into the emulsification tank and stir to make a homogeneous and transparent mixed solution. Then enter the homogenizer, after homogenization treatment, the particles of the dispersed phase in the emulsion will be finer and more uniform, and a highly stable product will be obtained. Put the homogeneous liquid into the cooling tank to cool, exhaust, discharg...

Embodiment 2

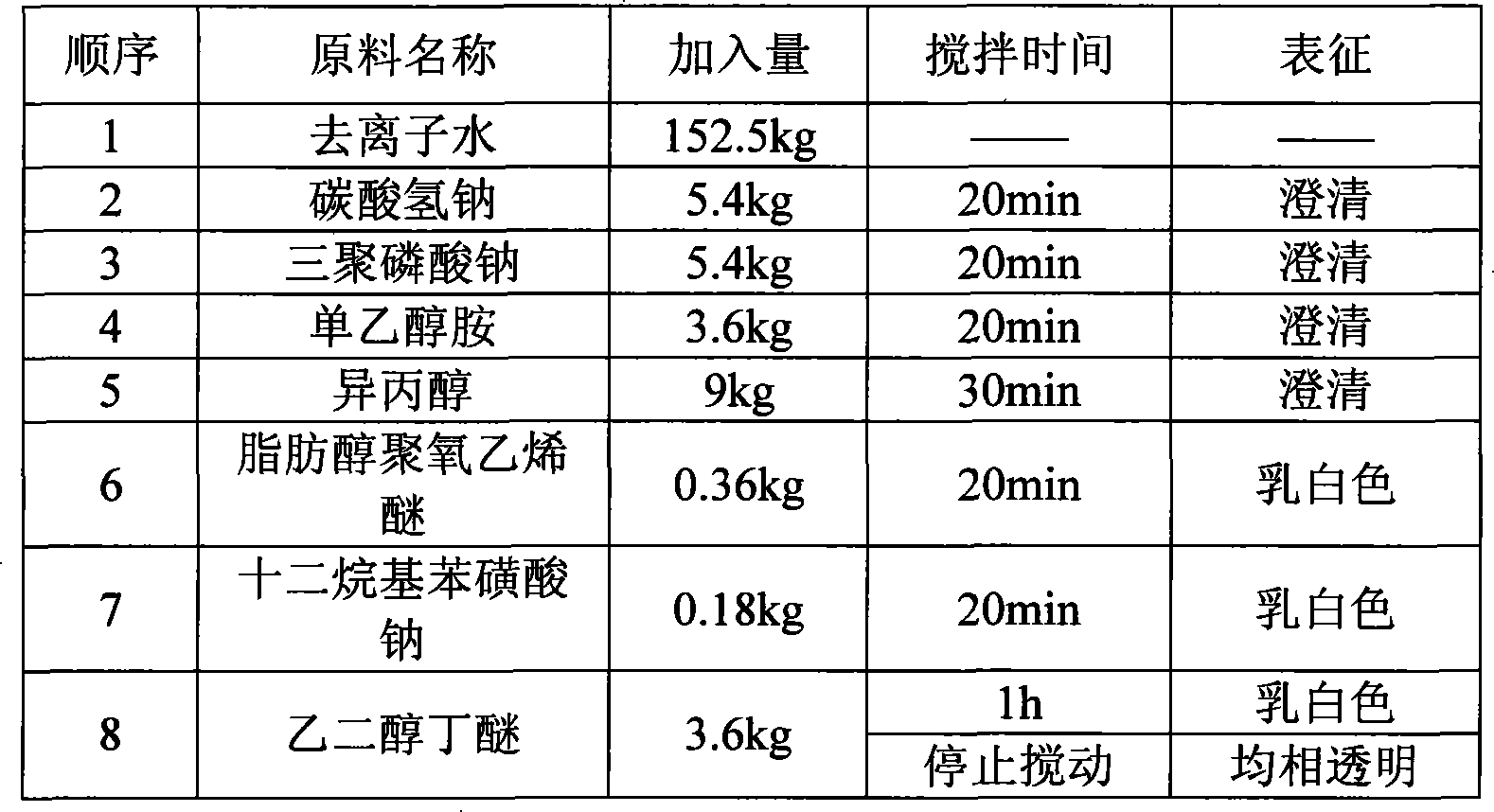

[0024] The operation method is the same as in Example 1, except that the contents of each component are different, see Table 2 for details.

[0025] List of raw materials in table 2 embodiment 2

[0026]

Embodiment 3

[0028] The operation method is the same as in Example 1, except that the contents of each component are different, see Table 3 for details.

[0029] List of raw materials in table 3 embodiment 3

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com