Method for extracting copper from mixed copper ores

A technology of mixed type and copper ore, which is applied in the field of extracting copper from low-grade mixed type copper ore, can solve the problems of high cost, difficulty in application, and serious pollution of the environment by flue gas, and achieve less investment, reduced investment in large-scale production, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

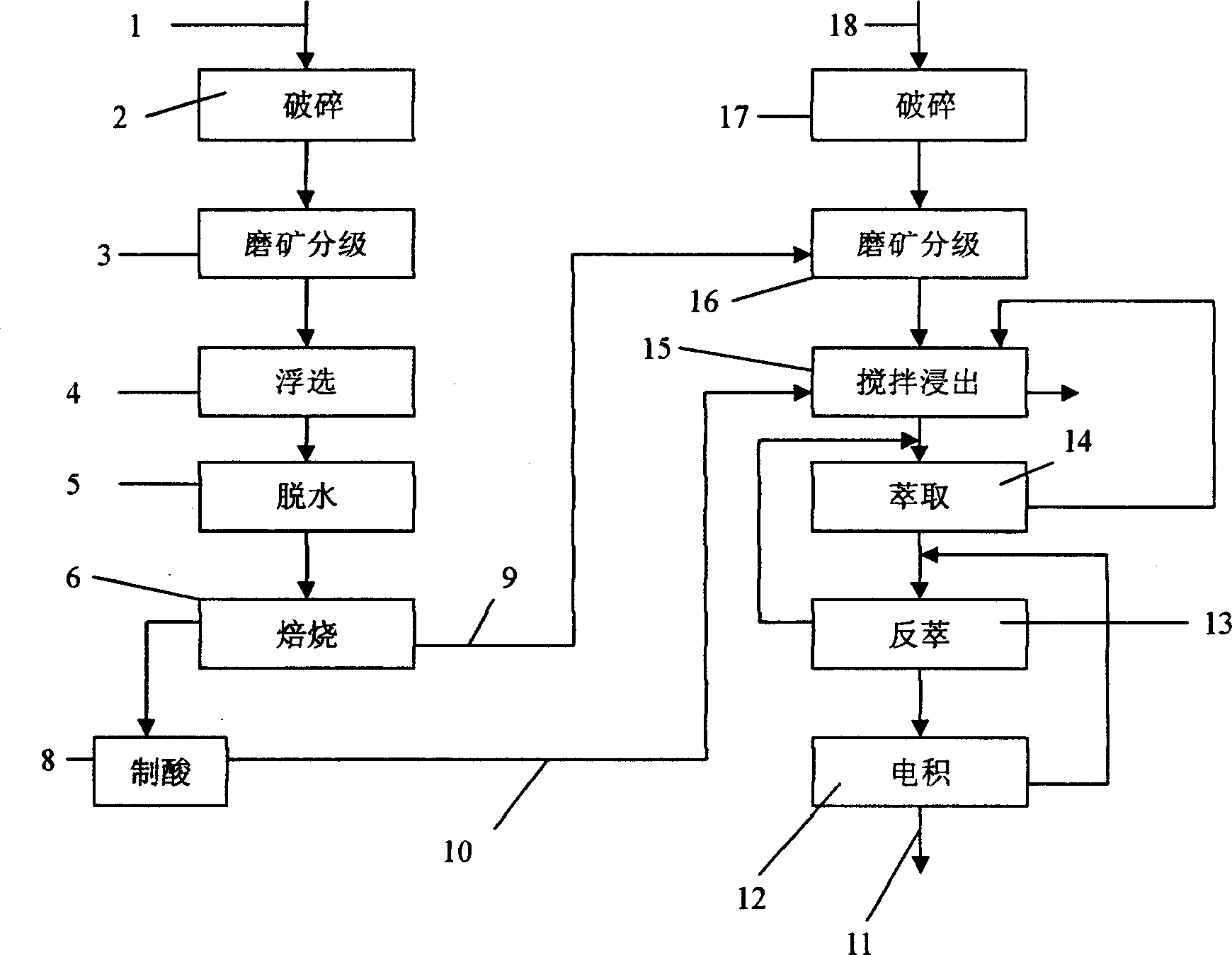

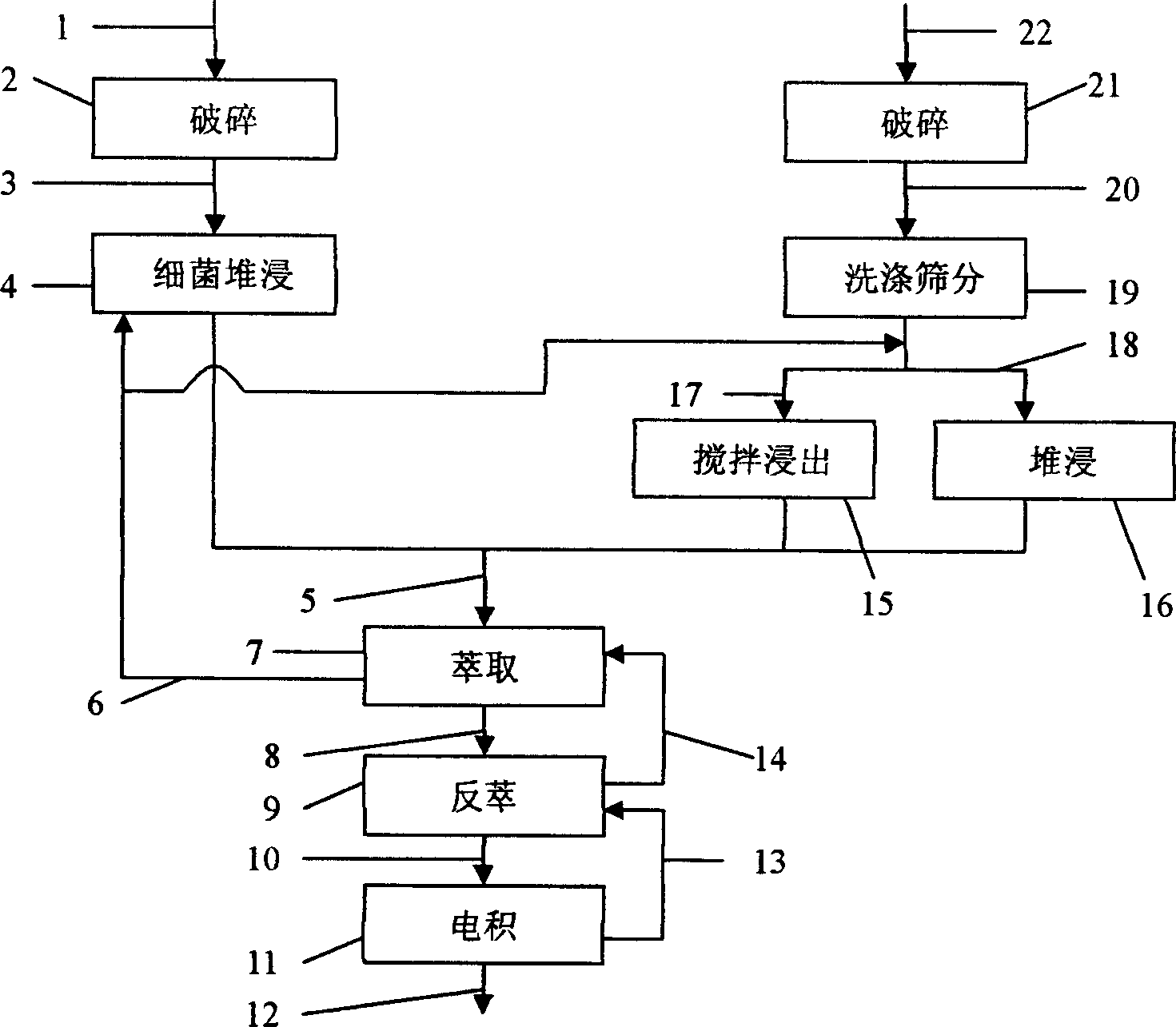

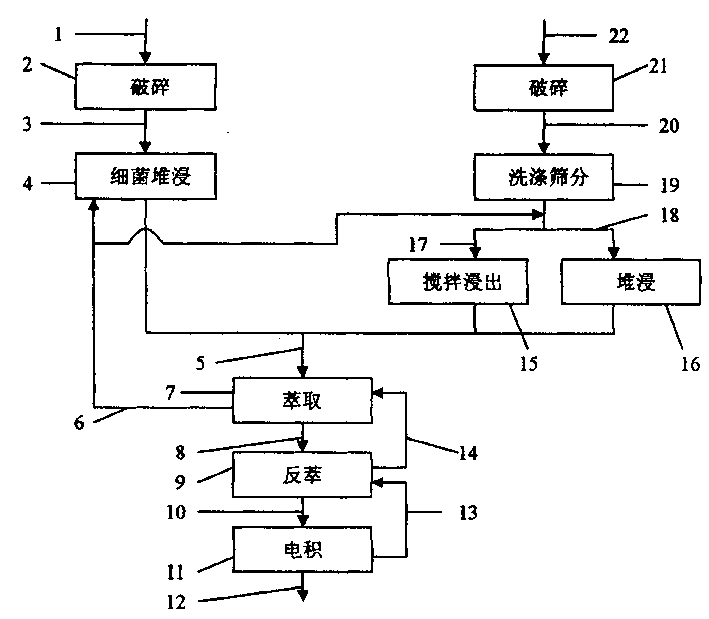

Method used

Image

Examples

Embodiment 1

[0020] The leached copper sulfide mineral composition (%): Cu 0.66, Fe 3.88, S 3.83, copper oxide mineral composition (%): Cu 9.29, Fe 17.68, S 0.85.

[0021]

[0022] At this time, the pH of the extraction liquid is significantly lower than the pH value of the spray liquid required by the bacterial leaching process, which is 2. Therefore, water is added to a part of the extraction liquid every day to adjust the pH to about 2.0 to supplement the bacterial heap leaching of sulfide ore.

[0023]

[0024] The stirring and leaching conditions of copper oxide slime are as follows: the ore particle size is -1mm, take 500 grams of ore samples, strengthen stirring and leaching at room temperature, mix and leaching with the residual extraction liquid, the pulp concentration is 25%, the leaching time is 3 hours, and the copper leaching rate is 89%.

Embodiment 2

[0026] The leached copper sulfide mineral composition (%): Cu 0.51, Fe 3.59, S 3.43, copper oxide mineral composition (%): Cu 6.06, Fe 15.60, S 20.00.

[0027]

[0028] At this time, the pH of the extraction residue is significantly lower than the PH value of the spray solution required by the bacterial leaching process, which affects bacterial activity. Therefore, a part of the extraction residue is adjusted to about 2.0 by adding water every day to supplement the bacterial heap leaching of sulfide ore.

[0029]

[0030]The stirring and leaching conditions of copper oxide slime are as follows: the particle size of the slime is -1mm, take 500 grams of ore samples, strengthen the stirring and leaching at room temperature, and use the remaining extraction liquid to adjust the slurry for leaching. The slurry concentration is 30%, leaching for 2 hours, and the copper leaching rate is 86%.

Embodiment 3

[0032] The leached copper sulfide mineral composition (%) Cu 0.71, Fe 4.04, S 3.93, the copper oxide mineral composition (%) Cu 7.47, Fe 18.12, S 0.28.

[0033]

[0034] At this time, the pH of the extraction liquid is significantly lower than the pH value of the spray liquid required by the bacterial leaching process, which affects the activity of bacteria. Therefore, a part of the extraction liquid is adjusted to about 2.0 by adding water every day, and used as a sulfide mineral agent.

[0035]

[0036] Copper oxide slime heap leaching conditions are as follows: slime size -1mm, take 500 grams of ore sample, intensify stirring and leaching at room temperature, mix and leaching with extraction residue, pulp concentration 40%, leaching for 3 hours, copper leaching rate 91.45%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com