Perovskite solar cell based on Spiro-OMeTAD/CuxS composite hole transport layer and preparation method thereof

A technology of hole transport layer and solar cell, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of poor stability and low mobility of organic hole transport layer, and achieve improved water stability and effective It is beneficial to the application and promotion, and the effect of improving photoelectric conversion efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

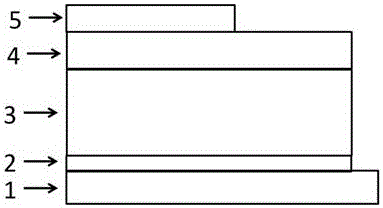

[0039] (1) Cleaning of transparent conductive substrate: In the experiment, the FTO conductive glass substrate should be cleaned and dried. Firstly, cut the conductive glass to the required size with a glass knife. After cutting, clean it with detergent, and then rinse it with deionized water. Then put it into an ultrasonic cleaner, clean it with acetone, ethanol, and ionized water in sequence, and finally dry it with nitrogen, so that the transparent conductive substrate with a clean surface required for the experiment can be obtained.

[0040] (2) Preparation of metal oxide electron transport layer: 0.1mol / L of SnCl 2 2H 2 O ethanol solution was stirred for 30 minutes to obtain the metal oxide precursor solution; the metal oxide precursor solution with different concentrations configured was evenly spin-coated on the conductive substrate with a glue machine, and then heated at 180 degrees Celsius after being shaken annealing for one hour to obtain a metal oxide electron tr...

Embodiment 2

[0046] (1) Cleaning of transparent conductive substrate: same as embodiment 1.

[0047] (2) Preparation of metal oxide electron transport layer: same as Example 1.

[0048] (3) Perovskite light-absorbing layer (CH 3 NH 3 PB 3 layer) preparation: with embodiment 1.

[0049] (4) Preparation of hole transport layer: the preparation steps of the organic hole transport layer (Spiro-OMeTAD layer) are the same as in Example 1, followed by vacuum evaporation of one layer of inorganic hole transport material Cu on the Spiro-OMeTAD layer. x S: Weigh 3mg of copper sulfide powder, and the background vacuum of the vacuum coating machine to be heated and evaporated is better than 10 -4 Pa, heating current 40A, evaporation time 30s.

[0050] (5) Preparation of the metal electrode layer: the prepared sample of the hole transport layer was placed in a vacuum evaporation device to evaporate a layer of gold thin film electrode through a thermal evaporation process.

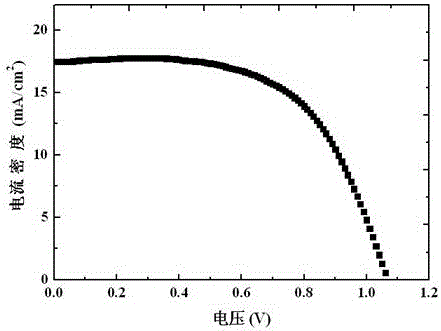

[0051] (6) Test: at AM...

Embodiment 3

[0053] (1) Cleaning of transparent conductive substrate: same as embodiment 1.

[0054] (2) Preparation of metal oxide electron transport layer: same as Example 1.

[0055] (3) Perovskite light-absorbing layer (CH 3 NH 3 PB 3 layer) preparation: with embodiment 1.

[0056] (4) Preparation of the hole transport layer: directly evaporate a layer of inorganic hole transport material Cu on the perovskite light-absorbing layer x S. Weigh 30mg of copper sulfide powder, and wait for the background vacuum of the vacuum coating machine to be thermally evaporated to be better than 10 -4 Pa, heating current 30A, evaporation time 3min.

[0057] (5) Preparation of the metal electrode layer: the prepared sample of the hole transport layer was placed in a vacuum evaporation device to evaporate a layer of gold thin film electrode through a thermal evaporation process.

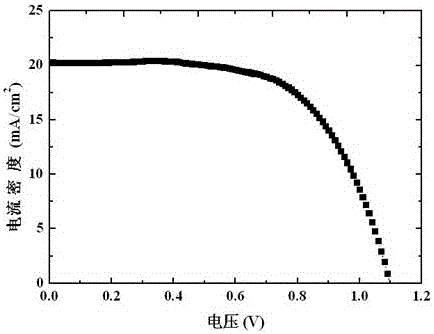

[0058] (6) Test: at AM 1.5, the effective area of the active layer is 0.09cm 2 The prepared perovskite solar cells...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Short circuit current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com