Preparation method of copper sulphide nano-powder with different stoichiometric ratios

A stoichiometric ratio and nano-powder technology, applied in the field of nanomaterials, can solve the problems of difficult separation of products, expensive raw materials, complicated processes, etc., and achieve the effects of controllable stoichiometric ratio, easy availability of raw materials, and short process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

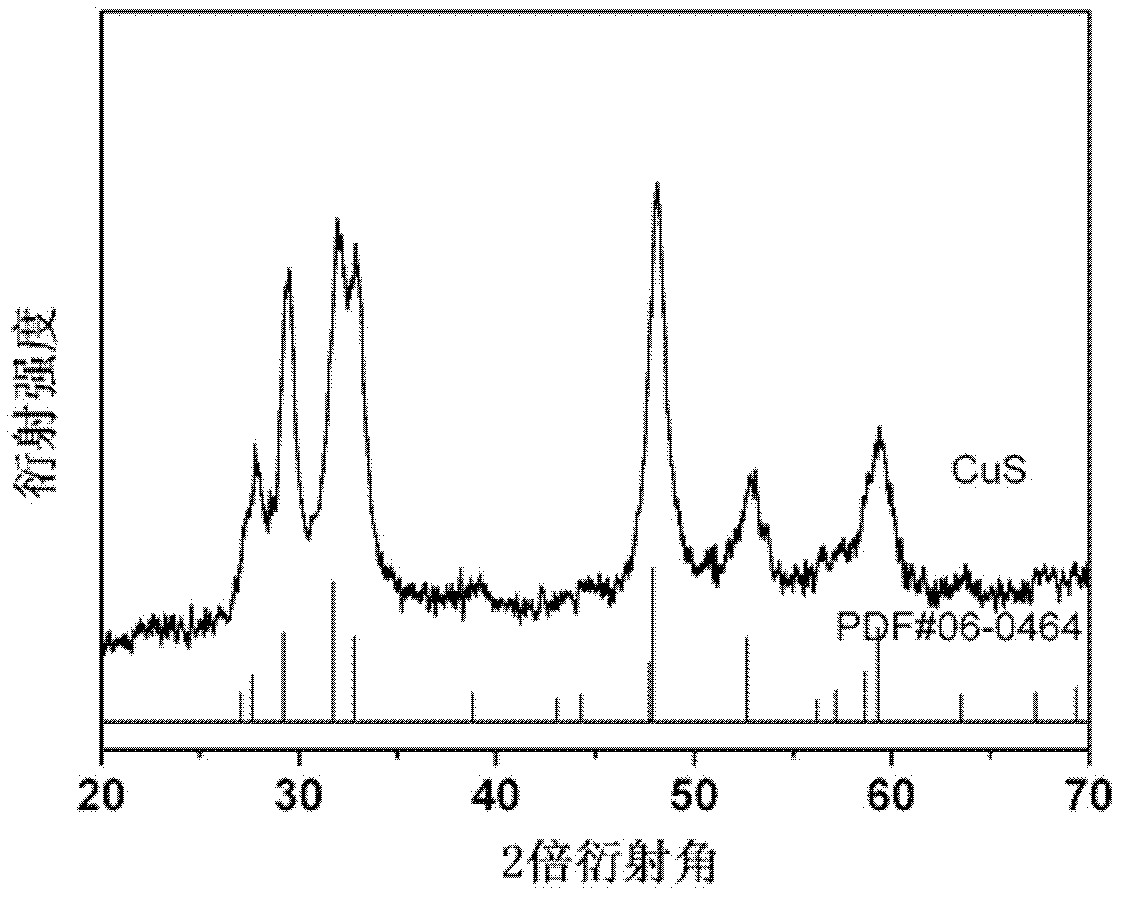

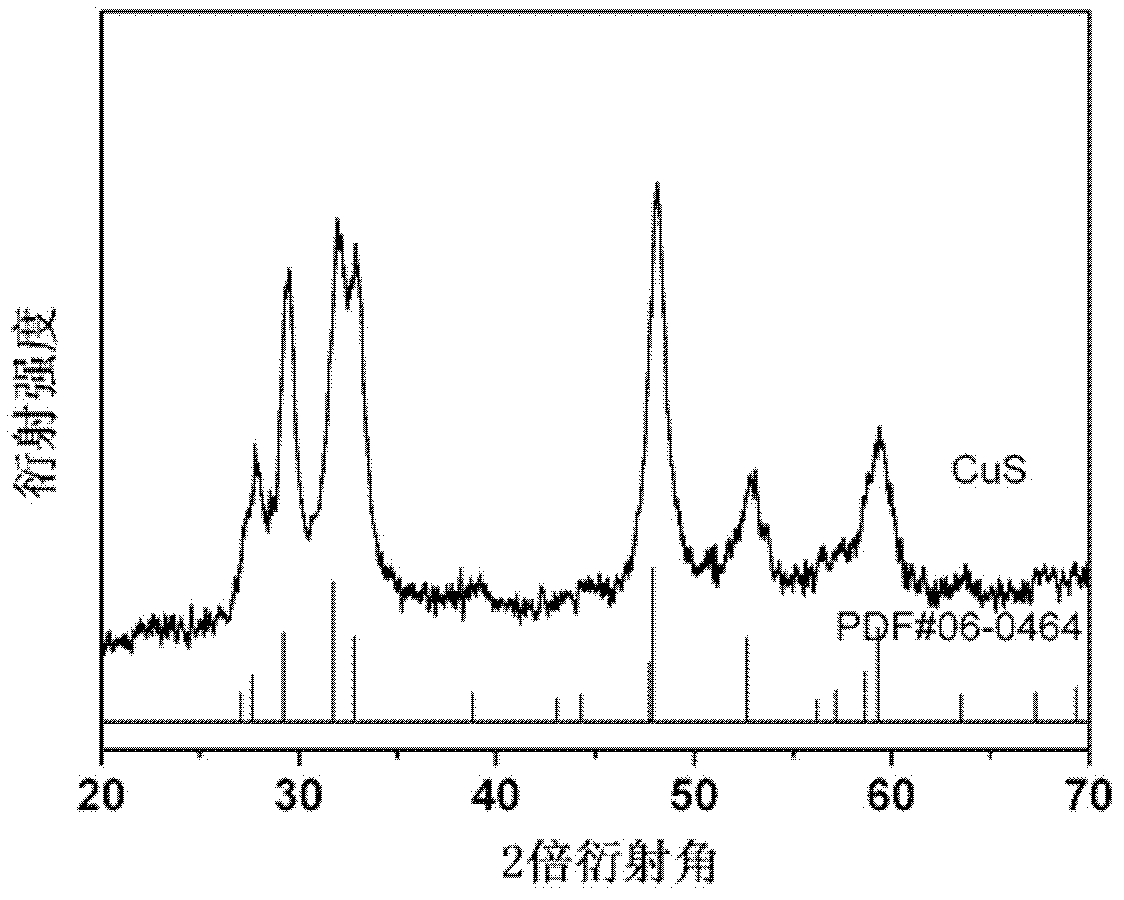

Image

Examples

example 1

[0011] According to the molar ratio: elemental copper: elemental sulfur = 2.5:1 configuration, weigh the copper powder and sulfur powder of the corresponding mass, put them in a ball mill jar, put stainless steel balls with a ball-to-material ratio of 20:1, seal, and vacuumize. After being filled with argon protective gas, the copper sulfide (Cu 2.5 S) Nanopowder.

example 2

[0013] According to the molar ratio: elemental copper: elemental sulfur = 2.2:1 configuration, weigh the copper powder and sulfur powder of the corresponding mass, put them in a ball mill jar, put in a stainless steel ball with a ball-to-material ratio of 20:1, seal it, and vacuumize it. After being filled with argon protective gas, the copper sulfide (Cu 2.2 S) Nanopowder.

example 3

[0015] According to the molar ratio: elemental copper: elemental sulfur = 2:1 configuration, weigh the copper powder and sulfur powder of the corresponding mass, put them in a ball mill jar, put in a stainless steel ball with a ball-to-material ratio of 20:1, seal it, and vacuumize it. After being filled with argon protective gas, the copper sulfide (Cu 2 S) Nanopowder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com