Method for smelting low-sulfur copper concentrate

A smelting method and technology of copper concentrate, which is applied in the field of smelting low-sulfur copper concentrate, can solve the problems of hidden waste water pollution, high power consumption in electrowinning, and high production cost, and achieve short construction period, short process flow and low investment. little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

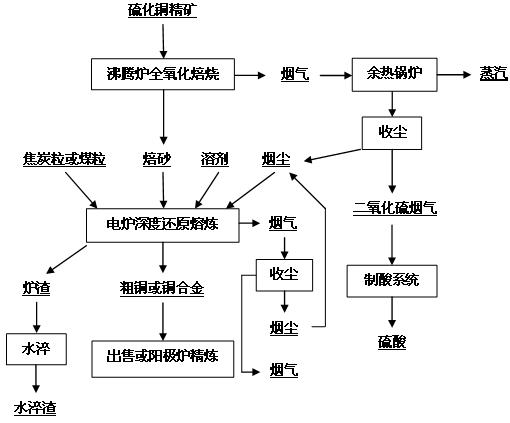

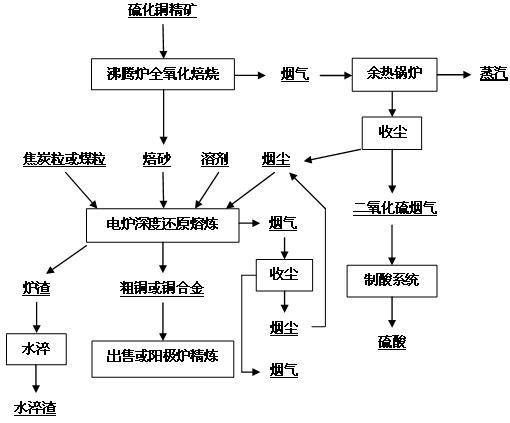

Method used

Image

Examples

Embodiment 1

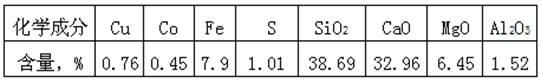

[0038] The main chemical components of copper sulfide concentrate are listed in Table 1.

[0039] Table 1 The chemical element composition of embodiment one copper sulfide concentrate

[0040]

[0041] Add 5% sulfur to the copper sulfide concentrate, continuously feed it into the fluidized fluidized furnace, feed air according to the air excess coefficient of 1.2, control the full oxidation roasting temperature within the range of 750-850 ° C, and the output flue gas passes through the waste heat boiler After treatment with electrostatic precipitator and bag filter, SO in the flue gas 2 The concentration is about 8%, and it is sent to sulfuric acid after purification; the obtained calcined sand and soot are combined to become roasted ore.

[0042] Table 2 Example 1 Copper sulfide concentrate fully oxidized roasting product ore chemical composition

[0043]

[0044] Add 20% lime and 8% powdered anthracite to the roasted ore according to the mass of the roasted ore. After ...

Embodiment 1

[0046] Table 3 Chemical Composition of Copper-Cobalt Alloy Product from Electric Furnace Melting in Example 1

[0047]

[0048] Table 4 Chemical Composition of Electric Furnace Smelting Slag in Example 1

[0049]

[0050] The electric furnace reduction smelting slag is water-quenched to a particle size of 3-20 mm, which can be stockpiled or used as road construction materials.

Embodiment 2

[0052] The main chemical components of copper sulfide and copper oxide mixed concentrate are listed in Table 5.

[0053] Table 5 The chemical element composition of embodiment copper disulfide and copper oxide mixed concentrate

[0054]

[0055] Add 8.2% sulfur to the mixed concentrate of copper sulfide and copper oxide, and continuously feed it into the fluidized furnace, and then feed the oxygen-enriched air with 28% oxygen according to the oxygen-enriched air excess coefficient of 1.1, and control the full oxidation roasting temperature at 780~ In the range of 900℃, after the flue gas produced is treated by the waste heat boiler, electric dust collector and bag dust collector, the SO in the flue gas 2 The concentration is about 7.6%, and it is sent to sulfuric acid after purification; the obtained calcined sand and soot are combined to become roasted ore.

[0056] Table 6 Example copper disulfide and copper oxide mixed concentrate fully oxidized roasted ore product chem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com