Tertiary amine oxide with rosinyl three-membered phenanthrene ring structure and preparation method of tertiary amine oxide

A rosin-based ternary phenanthrene and tertiary amine oxide technology, applied in organic chemistry and other directions, can solve the problems of unsuitable chiral reagents, the alkyl chain has no chirality, and the processing is cumbersome, and achieves good anti-electrolyte ability, easy to degrade, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

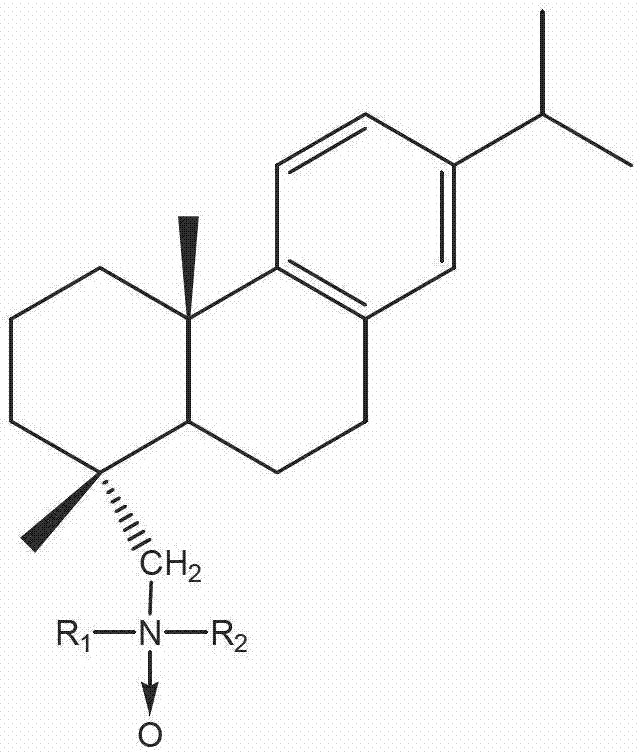

[0042] Such as figure 2 Shown, a kind of tertiary amine oxide containing rosin-based three-membered phenanthrene ring structure, its structural formula is as follows:

[0043] Among them, R 1 and R 2 C respectively 1 ~C 2 of alkyl.

Embodiment 2

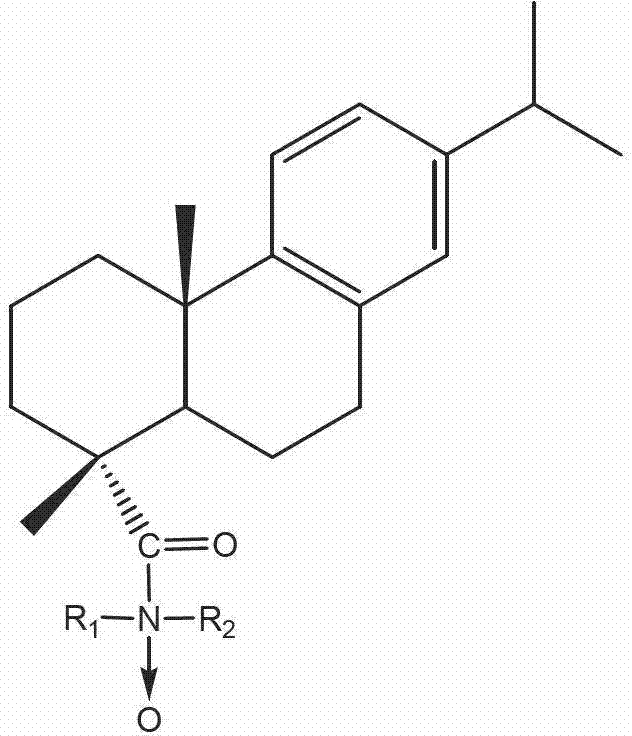

[0045] Such as image 3 Shown, a kind of tertiary amine oxide containing rosin-based three-membered phenanthrene ring structure, its structural formula is as follows:

[0046] Among them, R 1 and R 2 C respectively 1 ~C 2 of alkyl.

Embodiment 3

[0048] The preparation method of the tertiary amine oxide containing rosin base ternary phenanthrene ring structure as embodiment 1, comprises the following steps:

[0049] 1. Preparation of intermediate tertiary amine N,N-dimethyl dehydroabietylamine

[0050] Add 14.30g of dehydroabietylamine and 15ml of absolute ethanol into a three-necked flask equipped with a reflux condenser, a constant pressure dropping funnel and a thermometer, heat and stir at 35~40°C until the dehydroabietylamine is completely dissolved, then stop heating. Then, under stirring, use a constant pressure dropping funnel to slowly drop formic acid and formaldehyde solution in turn, so that the molar ratio of the three is 1:2.5:2.2, white smoke will be generated during the dropping of formic acid, and the temperature will automatically rise to 60~65°C , add formaldehyde dropwise, and the temperature will automatically drop to 45~50°C after the dropwise addition is completed. The dripping time is 25~30min,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com