Ternary positive electrode material having porous structure and preparation method thereof

A technology of positive electrode material and porous structure, which is applied in the field of ternary positive electrode materials and its preparation, can solve the problems of deterioration of electrochemical performance, reduction of lithium ion transmission, material structure damage, etc., achieve a balance between energy density and specific surface area, and shorten the diffusion distance , the effect of high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

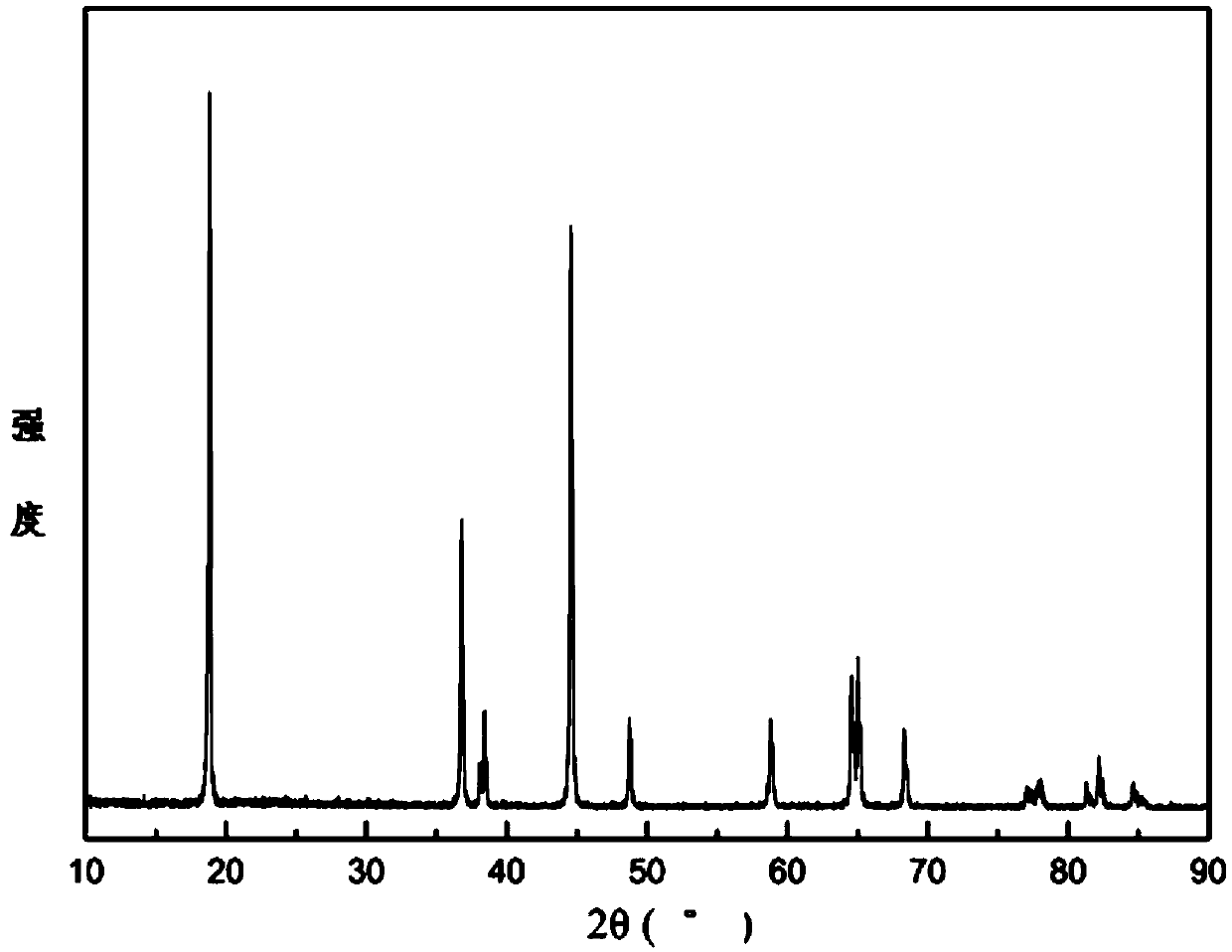

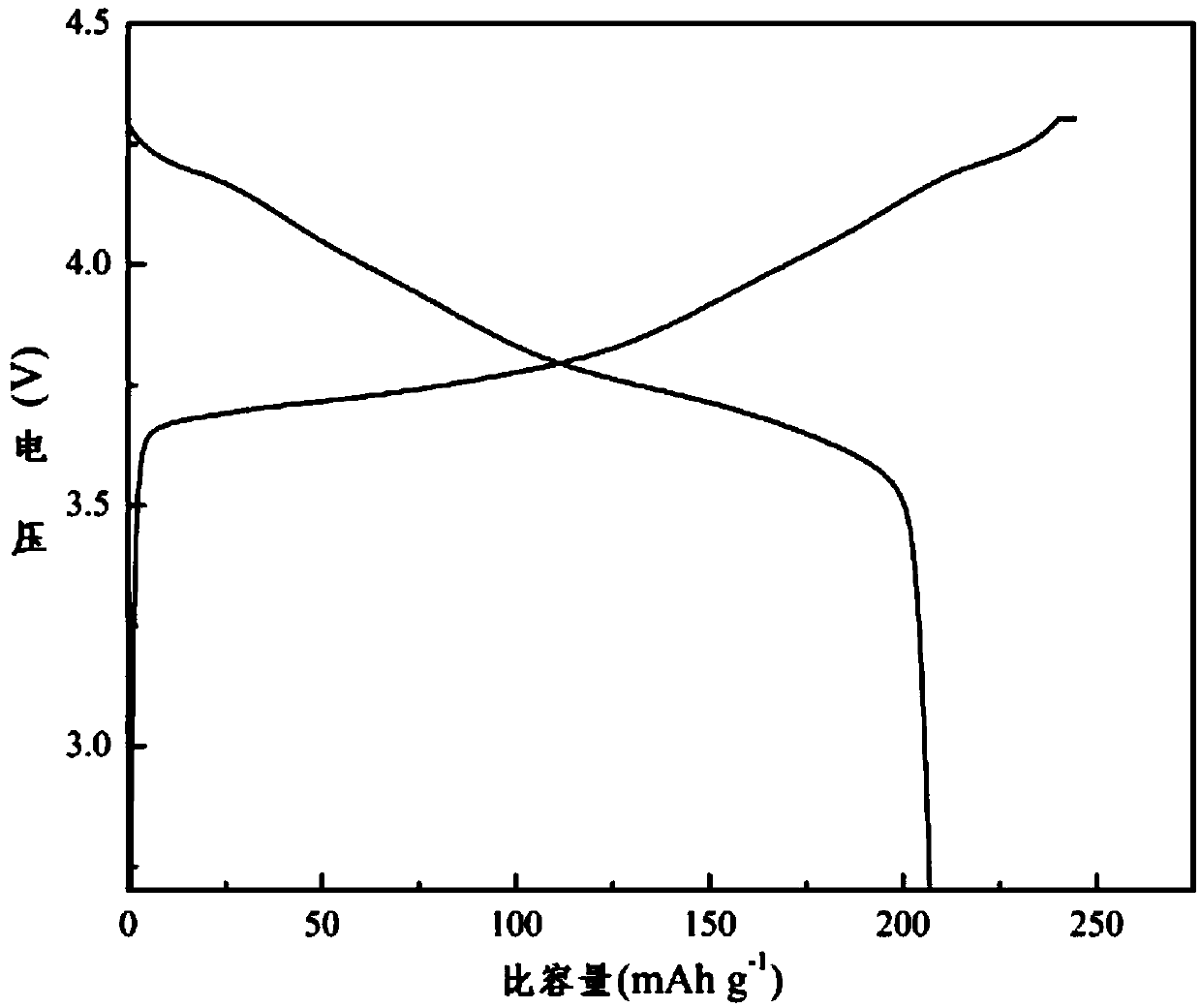

[0035] The preparation method of the ternary positive electrode material with a porous structure of the present invention: 80mL deionized water and 20mL triethylene glycol are prepared into a mixed solution in a 200mL beaker, and the total amount is 0.04mol (the ratio is 8:1:1) Ni(CH3 COO) 2 4H 2 O, Co(CH 3 COO) 2 4H 2 O and Mn(CH 3 COO) 2 2H 2 O and CO(NH 2 ) 2 Dissolve in the above mixture, place the beaker on a magnetic stirrer and stir for 1.5h to dissolve completely. Transfer the dissolved solution to a hydrothermal reaction kettle at 180°C for 16 hours. After it cools down naturally, filter it with suction, wash it three times with deionized water and absolute ethanol, and put the filtered powder in a vacuum drying oven at 120°C. Vacuum drying for 12 hours, the obtained powder was calcined at 500°C for 3 hours in an oxygen atmosphere, and after cooling, the obtained powder was mixed with an excess of 8% LiOH·H 2 O mixed and ground, first calcined at 480°C for 3...

Embodiment 2

[0042] The preparation method of the ternary positive electrode material with a porous structure of the present invention: 80mL deionized water and 20mL triethylene glycol are prepared into a mixed solution in a 200mL beaker, and the total amount is 0.04mol (the ratio is 6:2:2) Ni(CH 3 COO) 2 4H 2 O, Co(CH 3 COO) 2 4H 2 O and Mn(CH 3 COO) 2 2H 2 O and CO(NH 2 ) 2 Dissolve in the above mixture, place the beaker on a magnetic stirrer and stir for 1.5h to dissolve completely. Transfer the dissolved solution to a hydrothermal reaction kettle at 200°C for 10 hours. After it cools down naturally, filter it with suction, wash it three times with deionized water and absolute ethanol, and put the filtered powder in a vacuum drying oven at 120°C. Vacuum drying for 12 hours, the obtained powder was calcined at 450°C for 3 hours in an oxygen atmosphere, and after cooling, the obtained powder was mixed with an excess of 8% LiOH·H 2 O mixed and ground, first calcined at 450°C for...

Embodiment 3

[0045] Ternary cathode material LiNi 0.7 co 0.2 mn 0.1 o 2 The preparation method is the same as that of Example 2, the difference being that the molar ratio of Ni, Co and Mn in the raw material is 7:2:1. According to the same test conditions as in Example 2, the first charge capacity was measured to be 213.4mAh / g, and at a charge and discharge current of 1C, the capacity retention rate after 100 cycles was 94.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com