Method for measuring starch content of oceanic microalgae cell

A technology of starch content and marine microalgae, which is applied in the preparation of test samples, material analysis by observing the impact on chemical indicators, and analysis by making materials undergo chemical reactions can solve the problems of incomplete starch extraction and experimental problems. Long cycle, expensive and other issues, to achieve the effect of long color stability time, short experiment cycle, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

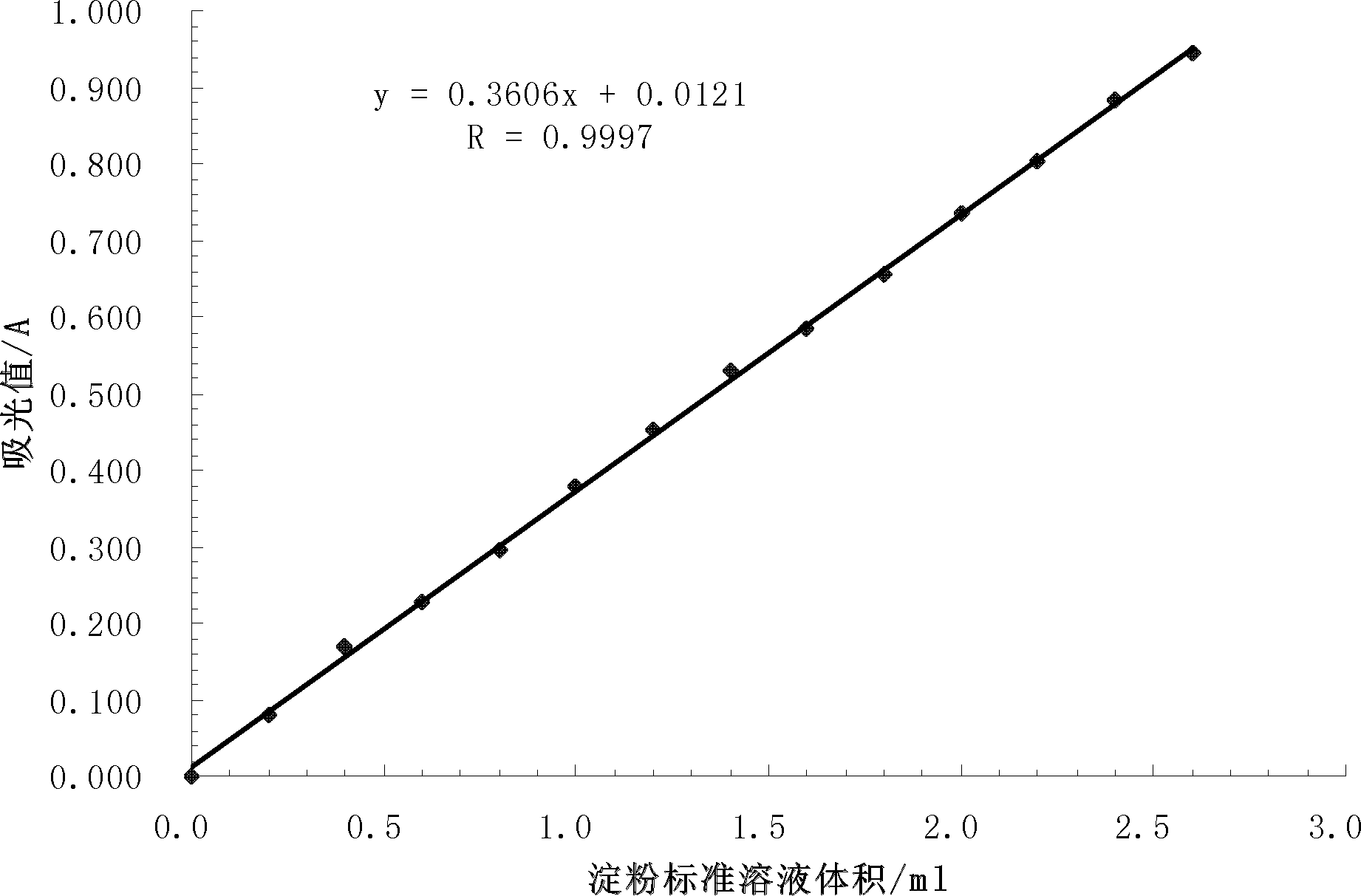

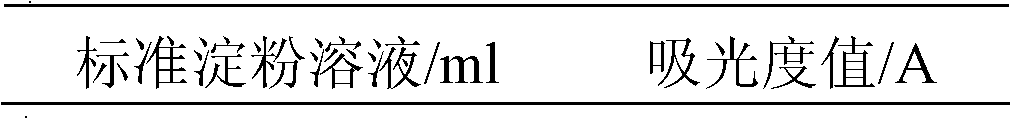

[0026] (1) Drawing of starch standard curve

[0027] Accurately weigh about 0.10g of analytically pure starch, dissolve it in boiled deionized water, and after cooling, set the volume to a 1L volumetric flask to prepare a starch standard solution; then measure different volumes of the starch standard solution, and use 0.8g / mL calcium nitrate solution was added to 4ml, add 0.15mL 0.01mol / L I 2 -KI standard solution, shake well, utilize T6 new century ultraviolet-visible spectrophotometer to measure its absorbance value under 570nm wavelength respectively, add 0.15mL 0.01mol / L I to 0.8g / mL calcium nitrate solution of 4ml 2 -KI standard solution is used as a blank, the results are shown in the following table 1, and the volume of the starch standard solution is plotted with absorbance, see the appendix figure 1 .

[0028] Table 1 The absorbance values of different volume standard starch solutions

[0029]

[0030]

[0031] Such as figure 1 As shown, the abscissa is t...

Embodiment 2

[0054] Determination of starch content in microalgae samples

[0055] A. Centrifuge the marine microalgae culture solution cultivated with seawater to the equilibrium period at 3200 rpm for 7 minutes to obtain fresh microalgae mud;

[0056] B. Wash the fresh microalgae mud with 1 times of deionized water repeatedly for 3 times, remove the impurities in the reaction system and change the osmotic pressure inside and outside the cells;

[0057] C. After repeated freezing and thawing of the microalgae mud washed with deionized water for 5 times, ultrasonically treat it for 15 minutes to break the microalgae cells;

[0058] D. Weigh 0.5231g, 0.5179g, 0.5082g of crushed microalgal algae mud respectively, mix them with 3ml of absolute ethanol, shake for 3min, then centrifuge at 3000rpm for 5min, discard the supernatant, and keep the precipitate.

[0059] E. Add 2ml of petroleum ether to the precipitate, mix and shake for 5 minutes, then add 3ml of 90% ethanol, mix and shake for 5 mi...

Embodiment 3

[0066] Determination of starch content in microalgae samples

[0067] A. Centrifuge the marine microalgae culture solution cultivated with seawater to the equilibrium period at 3500rpm for 5min to obtain fresh microalgae slime;

[0068] B. Wash the fresh microalgae mud with 1 times of deionized water repeatedly for 3 times, remove the impurities in the reaction system and change the osmotic pressure inside and outside the cells;

[0069] C. After repeated freezing and thawing of the microalgae mud washed with deionized water for 5 times, ultrasonically treat it for 15 minutes to break the microalgae cells;

[0070] D. Weigh 0.5033g, 0.5264g, 0.5096g of crushed microalgae slime, mix with 3ml of absolute ethanol, shake for 3min, centrifuge at 3000rpm for 5min, discard the supernatant, and keep the precipitate.

[0071] E. Add 2ml of petroleum ether to the precipitate, mix and shake for 5 minutes, then add 3ml of 90% ethanol, mix and shake for 5 minutes, centrifuge at 3000rpm fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com