Excess hydrogen sterilization washing machine

An excess hydrogen and washing machine technology, applied in the field of washing machines, can solve the problems of no softening improvement effect, hidden health risks, weak washing power, etc., and achieve the effects of good sterilization and disinfection effect, preventing clogging, and strengthening washing and cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

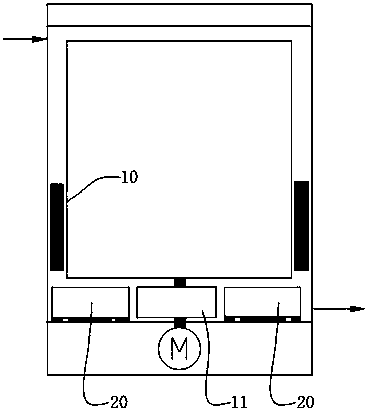

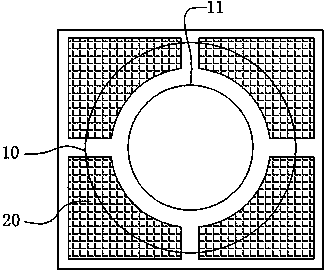

[0044] For the excess hydrogen sterilizing washing machine of the present embodiment, see figure 1 and figure 2 , including a washing machine barrel 10 and an electrolytic power supply. At least one electrolysis unit 20 is disposed inside the washing machine barrel 10 . Four electrolytic units 20 are arranged in the cylinder body 10 of the washing machine in this embodiment, and a pulsator 11 is arranged in the cylinder body 10 of the washing machine in this embodiment, and the electrolysis units 20 are evenly arranged along the circumference of the pulsator 11 in the cylinder body 10 of the washing machine .

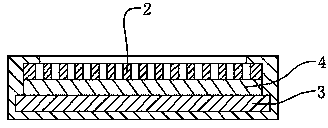

[0045] Such as image 3 and Figure 4 As shown, the electrolysis unit 20 includes at least one pair of cathode electrode 2 and anode electrode 3 . The electrolysis power supply is used to supply power to the cathode electrode 2 and the anode electrode 3 . A water-permeable diaphragm 4 is provided between the paired negative electrodes 2 and positive electrodes 3 ...

Embodiment 2

[0073] The excess hydrogen sterilizing washing machine of this embodiment is basically the same as Embodiment 1, and the changes different from Embodiment 1 are: 1) The water-permeable diaphragm 4 is closely attached to the negative electrode 2 and the positive electrode 3 at the same time, and the water-permeable diaphragm 4 is connected to the positive and negative electrodes. The distance between the poles is 0; 2) The two ends of the water-permeable diaphragm 4 are respectively longer than the cathode and anode electrodes.

Embodiment 3

[0075] The excess hydrogen sterilizing washing machine of this embodiment is basically the same as that of Embodiment 1, and the changes different from Embodiment 1 are: 1) the positive electrode 3 is an inert electrode made of carbonaceous materials such as graphite and activated carbon; 2) a water-permeable diaphragm 4 is a single-layer water-permeable diaphragm made of carbonaceous materials such as graphite and activated carbon; 3) The distance δ between the water-permeable diaphragm 4 and the positive electrode 3 1 is 0.5mm; 4) The distance δ between the water-permeable diaphragm 4 and the cathode electrode 2 2 It is 8mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com