Diffusion technique for silicon solar cell emitter

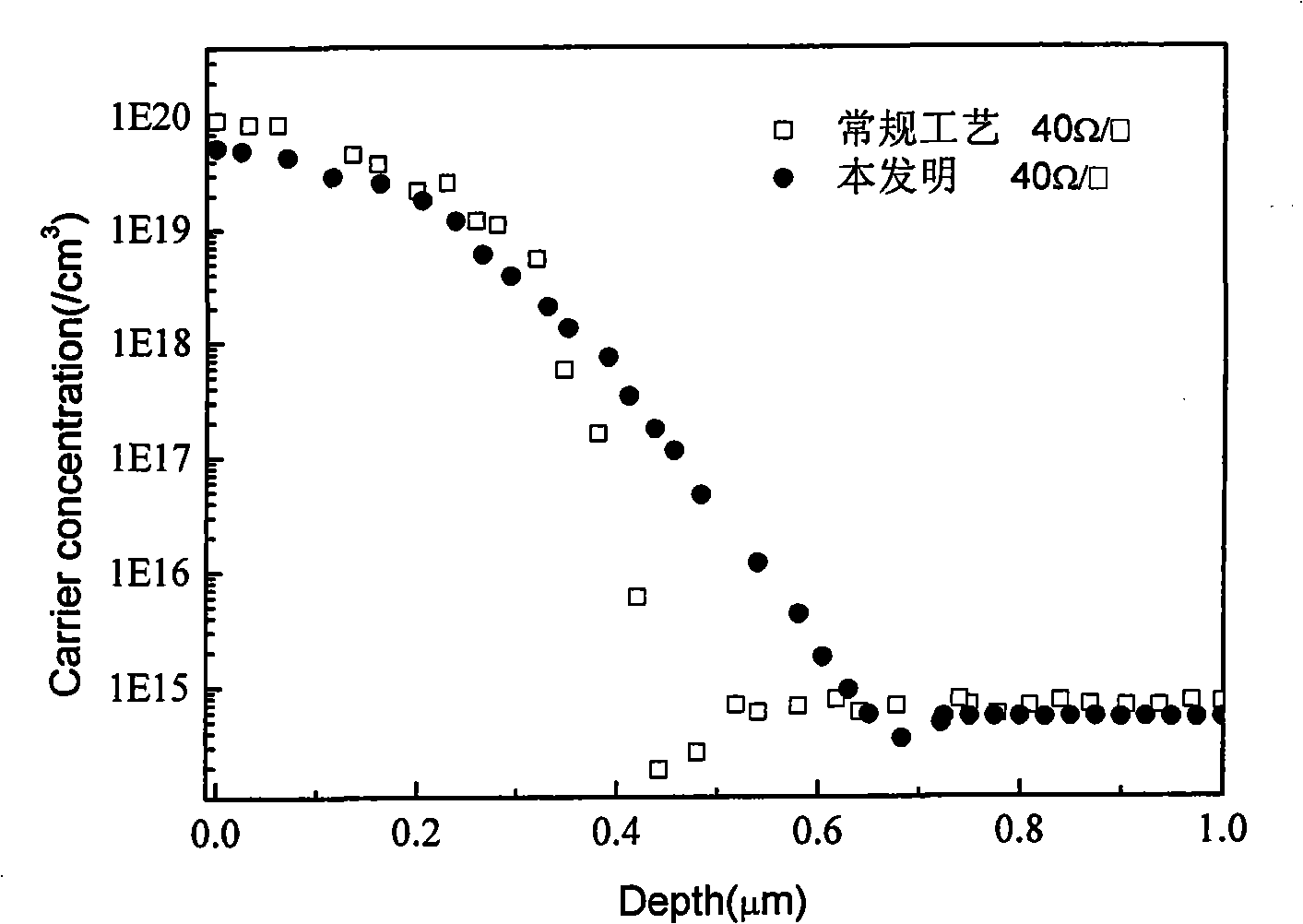

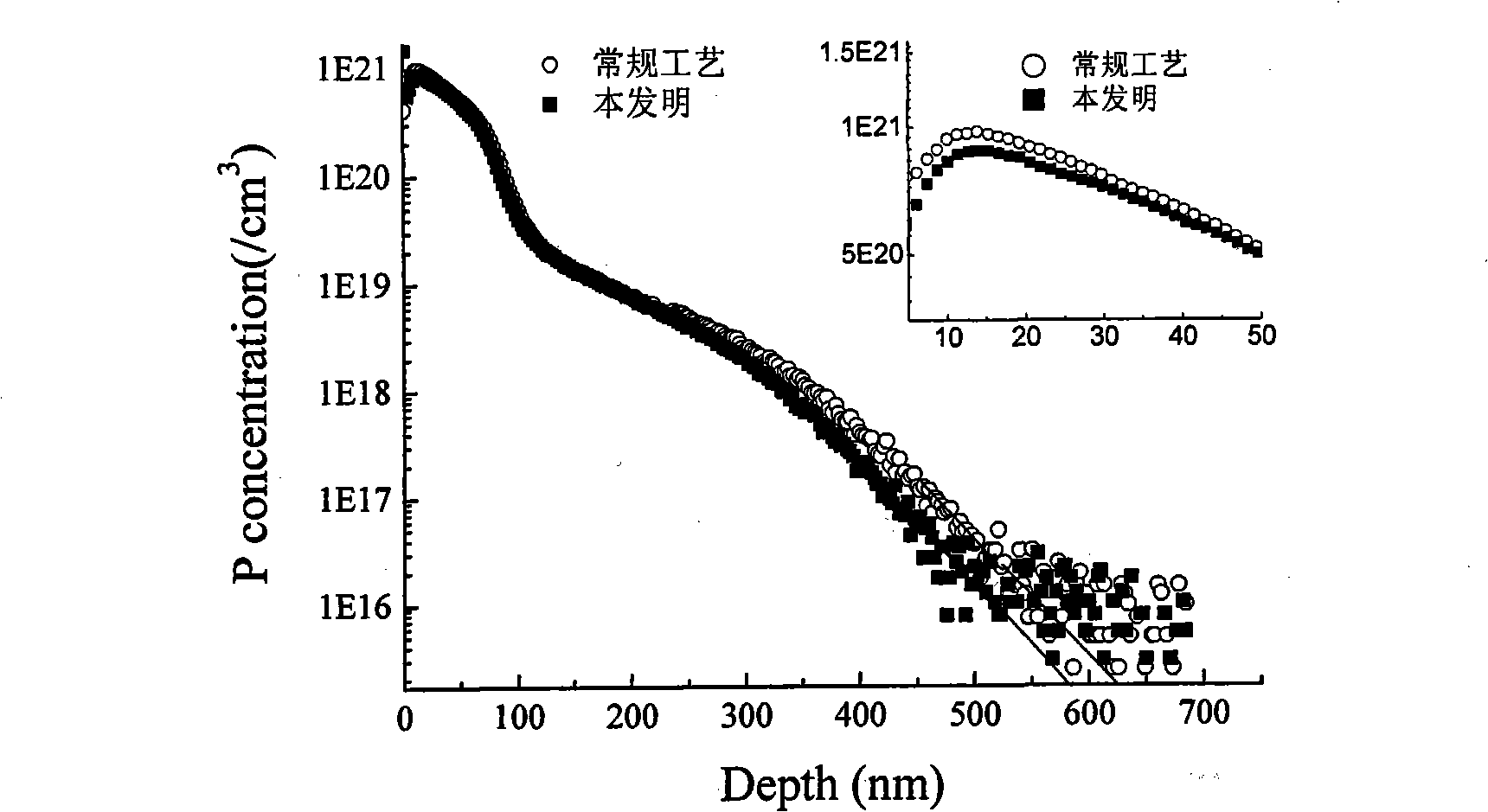

A silicon solar cell and diffusion process technology, applied in the field of diffusion process, can solve the problems of solar cell short-wave degradation, device efficiency reduction, solar cell short-circuit current loss, etc., achieve simple process and reduce the effect of Auger recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

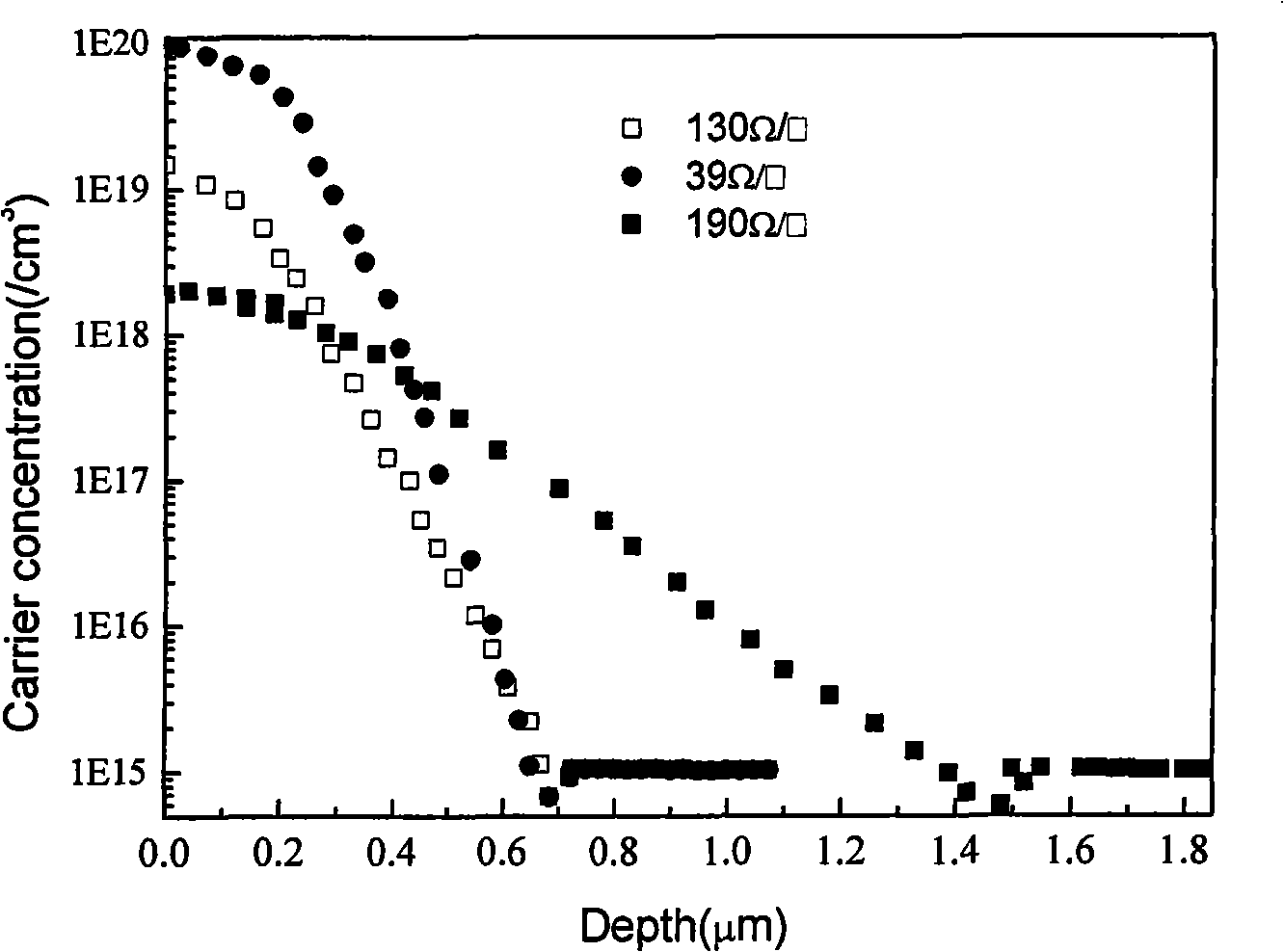

Examples

Embodiment 1

[0031] Use P-type monocrystalline silicon or polycrystalline silicon wafers, go through conventional surface texture, cleaning, drying and other processes, and then diffuse. The diffusion steps are as follows:

[0032] (1) The temperature is 820°C, 18 liters / min of protective nitrogen gas is introduced, and the quartz boat on which the silicon wafer is placed is slowly pushed into the diffusion furnace.

[0033] (2) After the quartz boat is pushed into a proper position, the temperature is raised from 820° C. to 840° C., and 4 liters / minute of oxygen is introduced for 5 minutes.

[0034] (3) At a temperature of 840°C, perform pre-diffusion: 1.8 liters / min of POCl is passed through 3 The source of nitrogen, the oxygen flow rate was changed to 3 L / min, and the time was 45 minutes.

[0035] (4) Carry out propulsive diffusion: stop carrying POCl 3 Source nitrogen and oxygen are introduced, the temperature rises from 840°C to 860°C for 8 minutes, and stabilizes at 860°C for 10 m...

Embodiment 2

[0040] Use P-type monocrystalline silicon or polycrystalline silicon wafers, go through conventional surface texture, cleaning, drying and other processes, and then diffuse.

[0041] (1) The temperature is 800°C, 18 liters / min of protective nitrogen gas is introduced, and the quartz boat on which the silicon wafer is placed is slowly pushed into the diffusion furnace.

[0042] (2) At 800° C., 4 liters / minute of oxygen was introduced for 5 minutes.

[0043] (3) At a temperature of 800°C, carry out a pre-diffusion process: feed 1.8 liters / minute to carry POCl 3 The source of nitrogen, the oxygen flow rate was changed to 3.0 L / min for 10 minutes.

[0044] (4) Carry out propulsive diffusion: stop carrying POCl 3 Source nitrogen and oxygen are introduced, the temperature rises from 800°C to 830°C for 5 minutes, and stabilizes at 830°C for 35 minutes. The total propulsion diffusion time was 40 minutes.

[0045] (5) After the diffusion is finished, cool down to the initial furnac...

Embodiment 3

[0049] Use P-type monocrystalline silicon or polycrystalline silicon wafers, go through conventional surface texture, cleaning, drying and other processes, and then diffuse.

[0050] (1) The temperature is 800°C, 18 liters / min of protective nitrogen gas is introduced, and the quartz boat on which the silicon wafer is placed is slowly pushed into the diffusion furnace.

[0051] (2) At 800° C., 4 liters / minute of oxygen was introduced for 5 minutes.

[0052] (3) At a temperature of 800°C, carry out a pre-diffusion process: 0.8 liters / min of POCl is introduced 3 The source of nitrogen, the flow rate of oxygen was changed to 1.2 L / min for 10 minutes.

[0053] (4) Carry out propulsive diffusion: stop carrying POCl 3 Source nitrogen and oxygen are introduced, the temperature rises from 800°C to 830°C for 5 minutes, and stabilizes at 830°C for 15 minutes. The total propulsion diffusion time was 20 minutes.

[0054] (5) After the diffusion is finished, cool down to the initial fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com