Fabrication method of lateral high voltage semiconductor device

A technology of lateral high voltage and manufacturing method, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as increased on-resistance, and achieve the effect of avoiding breakdown voltage and on-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

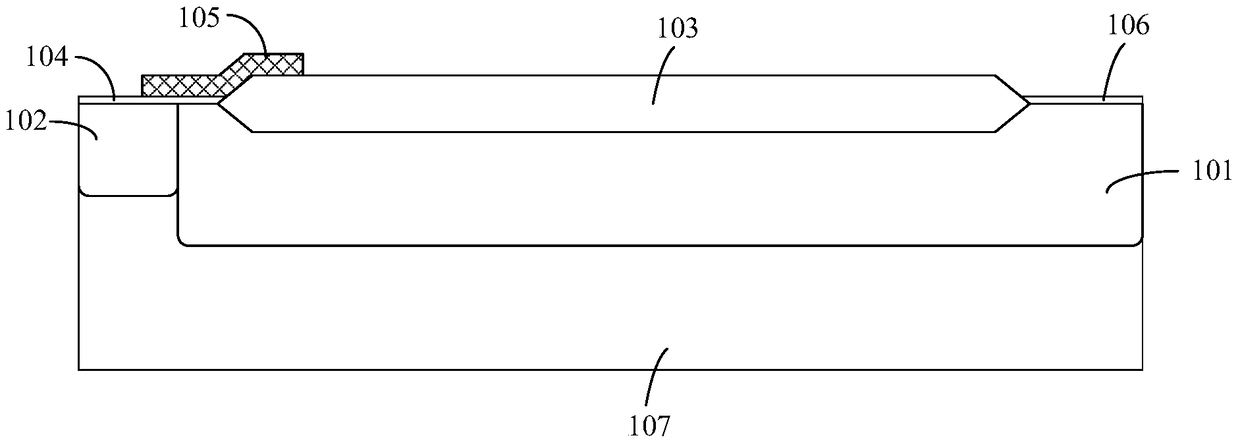

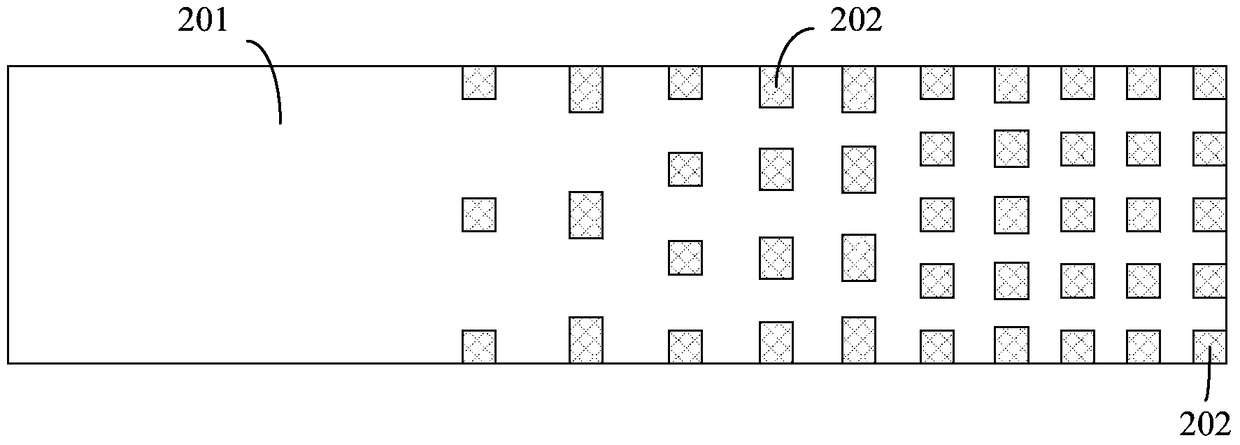

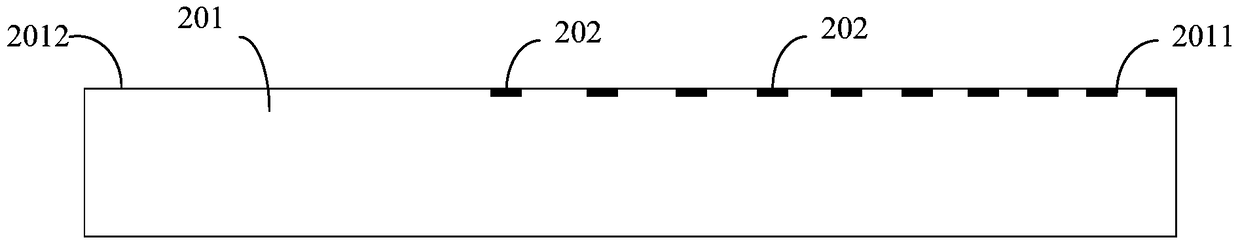

[0031] This embodiment provides a method for manufacturing a lateral high voltage semiconductor device. like Figures 2A-2H As shown, is a schematic flow chart of the method for fabricating a lateral high-voltage semiconductor device according to this embodiment.

[0032] like Figure 2A As shown, it is a schematic top view of forming each first ion-implanted doped region on the substrate; as Figure 2B Shown is a schematic cross-sectional view of forming each first ion-implanted doped region on the substrate.

[0033] In this embodiment, on the surface layer of the substrate 201 of the first conductivity type, each first ion-implanted doped region 202 of the second conductivity type is formed, and the distribution density of the first ion-implanted doped regions 202 is changed from the high-voltage The terminal 2011 gradually decreases toward the low-voltage terminal 2012 of the lateral high-voltage semiconductor device.

[0034] Both the first conductivity type and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com