Oxygen carrier gasifying combustion method for loading oxygen and device

A technology of oxygen carrier and oxygen carrier, which is applied in combustion methods, gas fuel burners, burners, etc., and can solve the problems of high energy consumption for carbon dioxide removal, energy consumption of carbon dioxide consumption, and impact on energy utilization efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

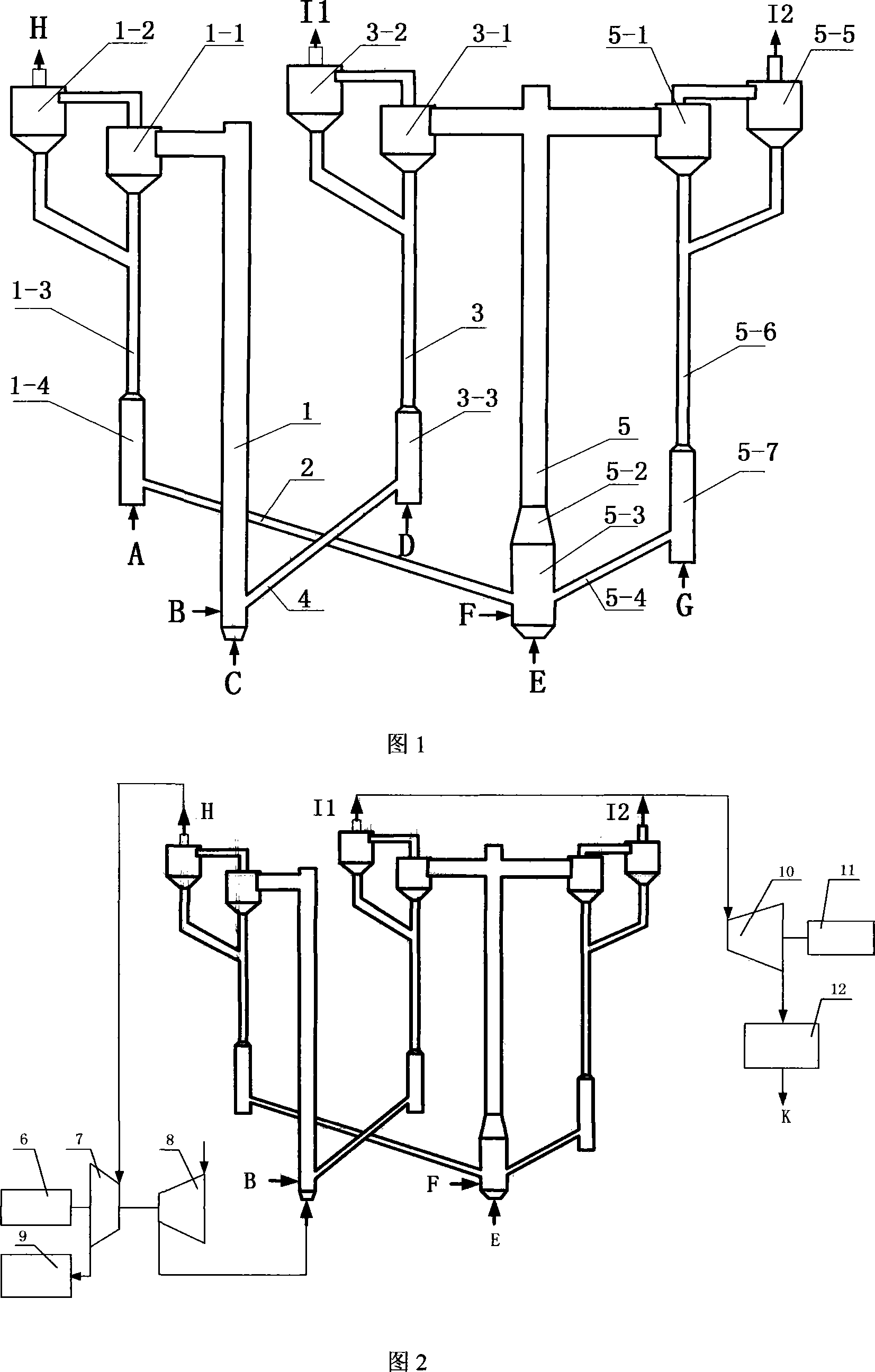

[0025] An oxygen-carrier oxygen-carrying oxidative combustion method, the low-valence metal oxide or metal element as the oxygen carrier is placed in the fluidized bed of the air reactor, and the metal oxide as the oxygen carrier is Fe 2 o 3 , FeO, Fe 3 o 4 , CuO, Cu 2 O, NiO, ZnO, the metal element as the oxygen carrier is Fe, Cu, Zn, Ni. Then, the fluidized air is introduced from the lower end C of the fluidized bed of the air reactor, and the low-valence metal oxide or metal elemental oxygen carrier reacts with the oxygen in the air to obtain the heated high-valence metal oxide, and then make it pass through two Stage separator separation; the separated high-temperature oxygen-depleted air is discharged from the upper end H of the separator, and the separated oxygen carrier passes through the return leg and enters the lower mixed gasification chamber of the fuel reactor fluidized bed; the fuel reactor flow The lower end E of the gasification bed is fed with gasification...

Embodiment 3

[0031] A method for realizing carbon dioxide separation during coal / natural coke / petroleum coke combustion by utilizing the present invention, that is, using coal / natural coke / petroleum coke for clean power generation and simultaneously realizing the separation of carbon dioxide. Referring to Fig. 2, after the air is compressed by the compressor 8, it becomes high-pressure air, enters the fluidized bed of the air reactor of Example 1, and reacts with the reduced oxygen carrier to obtain high-temperature, high-pressure, oxygen-poor air and carries oxygen through the air reactor The body separator is separated, and the high-pressure oxygen-poor air enters the turbine 7 to expand and do work, driving the generator 6 to generate electricity, and the exhaust gas from the turbine 7 enters the waste heat recovery power generation system 9 to generate electricity or steam. The oxygen carrier separated by the oxygen carrier separator of the air reactor enters the fluidized bed of the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com