Method and apparatus for producing and heating carbonaceous fuel gasifying agent

A technology of gasification agent and fuel inlet, which is applied in the manufacture of combustible gas and petroleum industry, etc. It can solve the problems of large consumption of pure O2 and achieve the effect of less external dependence and low emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] According to the aforementioned literature "Using NiO / NiAl at 1200°C 2 o 4 Preparation of NiO / NiAl 2 o 4 Oxygen carrier particles. Incorporate Ni-free Al with a particle size close to that of the prepared oxygen carrier particles in the oxygen carrier particles 2 o 3 particles to increase the heat capacity of the bed. Then the oxygen carrier particles were mixed with Al 2 o 3 The mixture of particles is charged into a batch regenerative reactor.

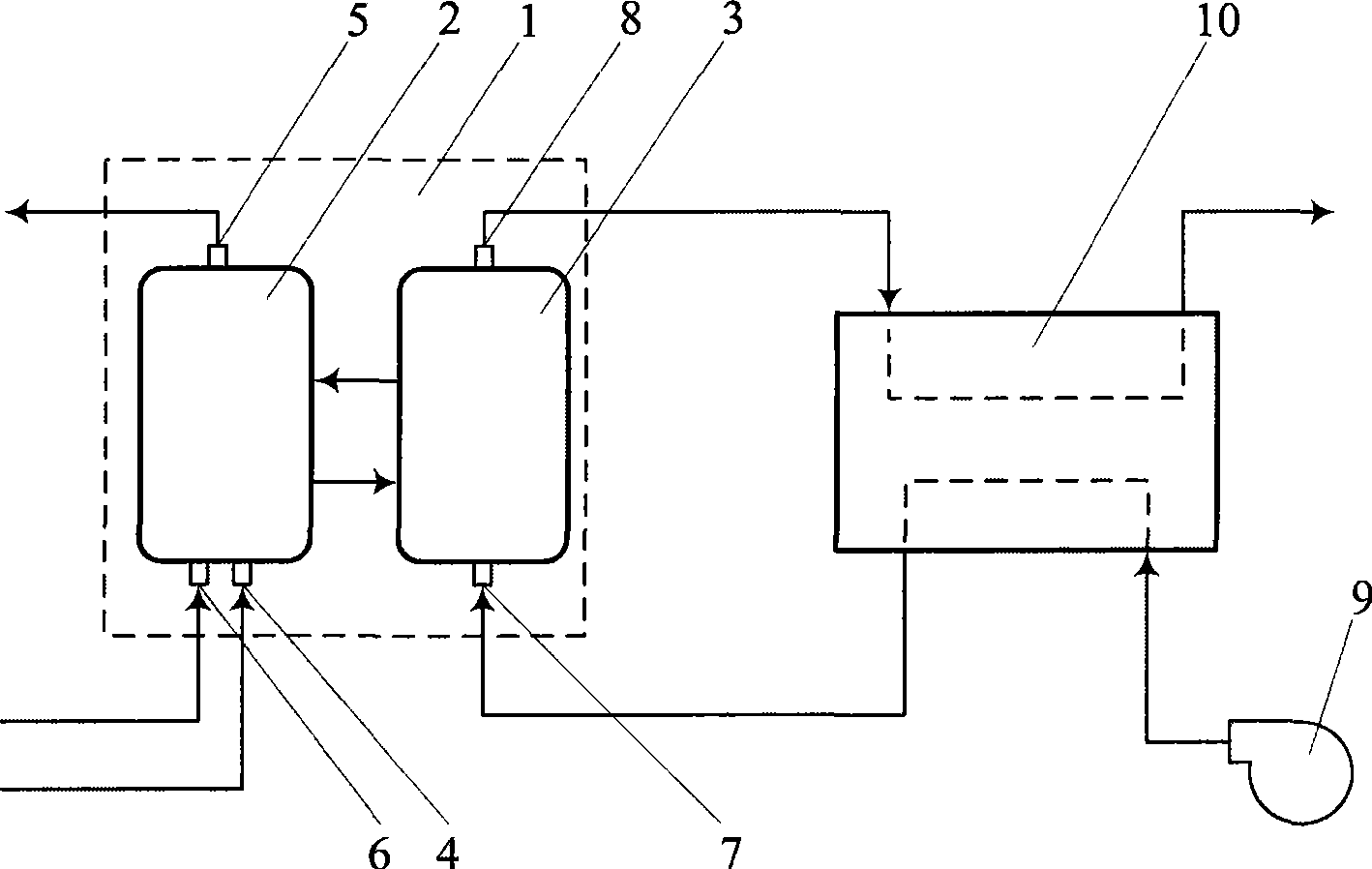

[0082] In this example, three batch regenerative reactors are used. In operation, one batch regenerative reactor is used for reduction operation, one batch regenerative reactor is used for oxidation operation, and one batch regenerative reactor is used for standby.

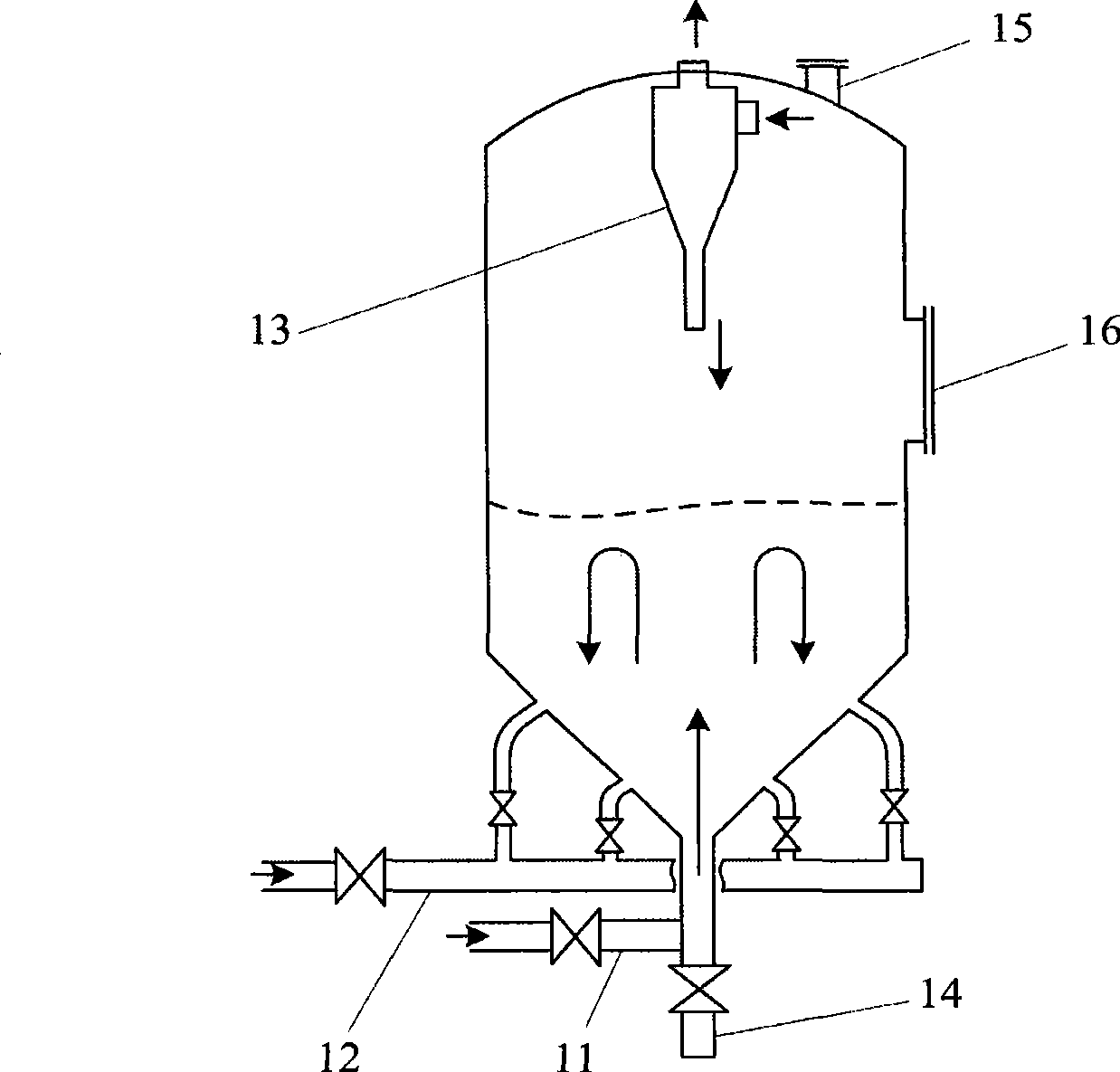

[0083] The structure of the batch regenerative reactor used is as follows figure 2 shown. The batch regenerative reactor is a cylinder with a conical bottom lined with refractory heat storage material. There is a spout air inlet 11 at the bottom of th...

Embodiment 2

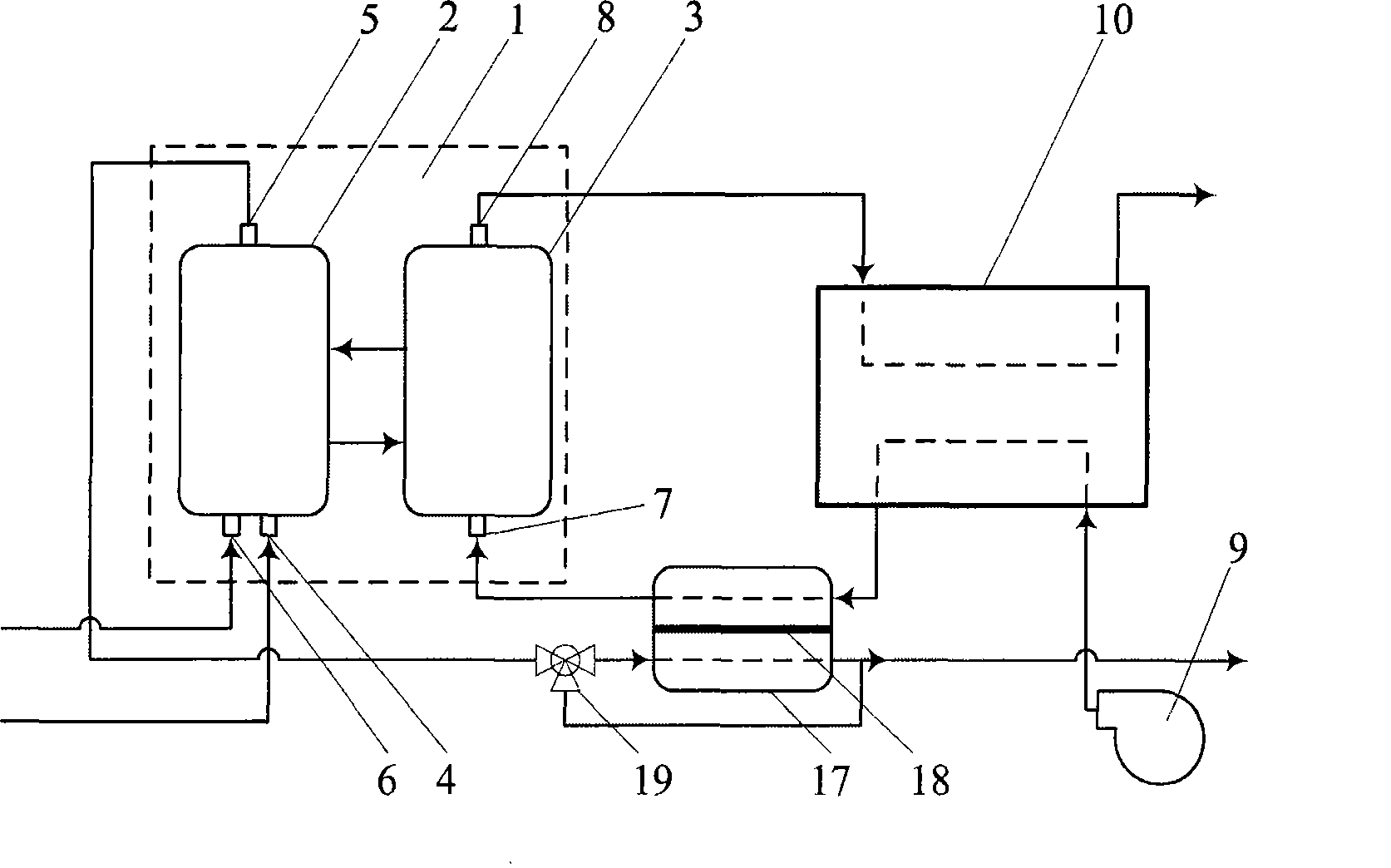

[0090] Such as image 3 As shown, the oxygen separator 17 is a device with a built-in oxygen permeable membrane 18. The oxygen permeable membrane divides the inner space of the oxygen separator 17 into two parts. Flow through one side of the oxygen permeable membrane in the oxygen separator 17, and then send to the gasifier; from the blower, the air preheated by the heat exchange network 10 flows countercurrently through the other side of the oxygen permeable membrane, and then enters the air reaction Air inlet 7 of device 3. The side here is a logical concept, and the actual device is a multilayer film sandwich structure. Before the externally transported gasification agent enters the oxygen separator 17, a diverter three-way valve 19 can be set to allow part of the externally transported gasification agent to bypass the oxygen separator 17. By adjusting the diverter three-way valve 19, the gasification side O can be adjusted. 2 concentration.

[0091] The oxygen permeable...

Embodiment 3

[0094] Such as Figure 4 As shown, the oxygen separator 17 is equipped with a solid oxygen selective adsorbent 20, and the oxygen separator 17 is provided with an air inlet connected to an air source, a waste gas vent, and an external gasification agent pipeline and a chemical looping combustion system for external gasification. The inlet of the gasification agent connected with the gasification agent pipeline, and the outlet of the oxygen-containing oxidizer connected with the gasification agent pipeline of the degasification furnace. Here, the outlet air of the blower is used as the air source. There are two oxygen separators 17 that operate interchangeably. During operation, one of the oxygen separators is fed with air from a blower, cooling the adsorbent bed and allowing the adsorbent to adsorb O 2 , the air after absorbing oxygen is directly discharged to the atmosphere through the exhaust gas vent; in the other oxygen separator, the cold external gasification agent fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com