Solar energy and methanol fuel chemical-looping combustion power generation system and method

A chemical chain combustion, methanol fuel technology, applied in the directions of light radiation generators, generators/motors, machines/engines, etc., can solve the problem of low initial temperature at the inlet of gas turbines, and achieve high initial temperature, simple structure, and reduced Effect of use of fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

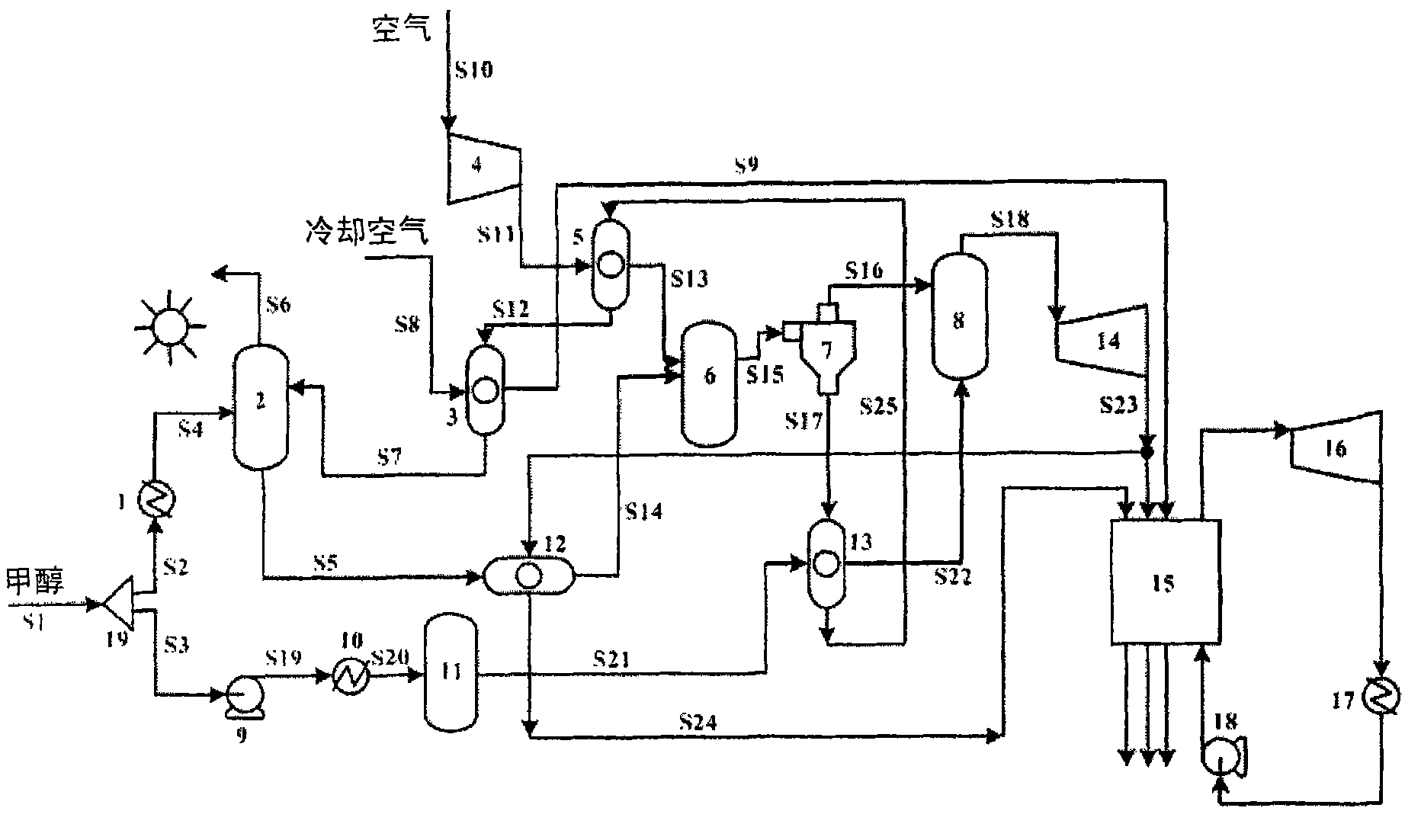

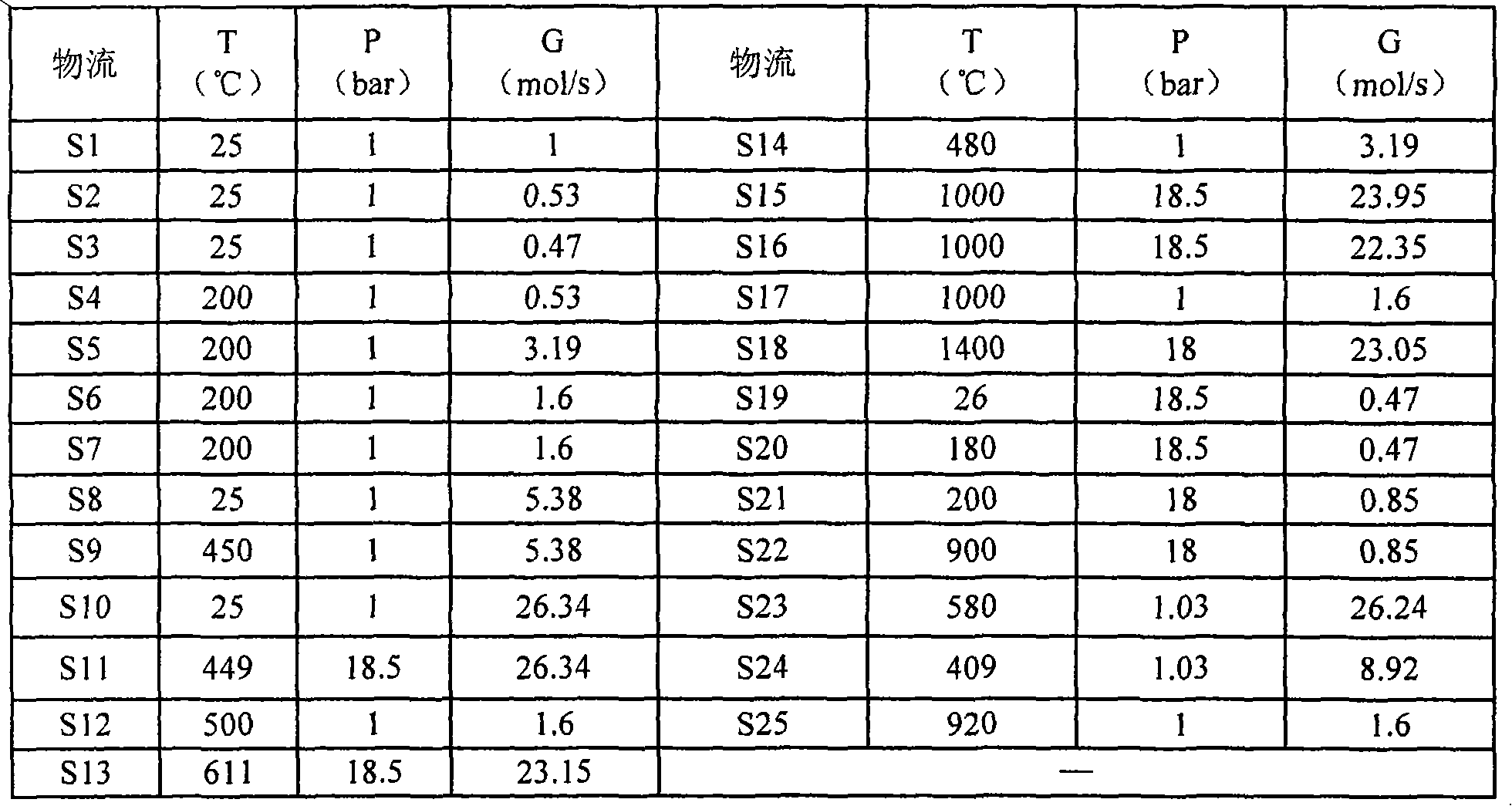

[0047] The present embodiment system consists of preheaters 1, 10, pumps 9, 18, gas-solid heat exchangers 3, 5, 12, 13, flow splitter 19, solar heat collection-reduction reactor 2, solar heat collection-decomposition reactor 11. Oxidation reactor 6, compressor 4, cyclone separator 7, afterburning combustion chamber 8, gas turbine 14, waste heat boiler 15, steam turbine 16, and condenser 17. The specific process is:

[0048] Methanol S1 is divided into two streams S2 and S3 through the flow divider 19 and enters the system. Methanol S2 enters the solar energy collection-reduction reactor 2 after being preheated by the preheater 1, and the preheating heat source is gathered by the trough solar collector 200 ~ 300 ℃ medium and low temperature solar thermal energy. In the reduction reactor, methanol and Fe 2 o 3 The circulating particles S7 undergo a reduction reaction. After the reaction, methanol is oxidized to the gaseous product CO 2 and water vapor S6, Fe 2 o 3 It is r...

Embodiment 2

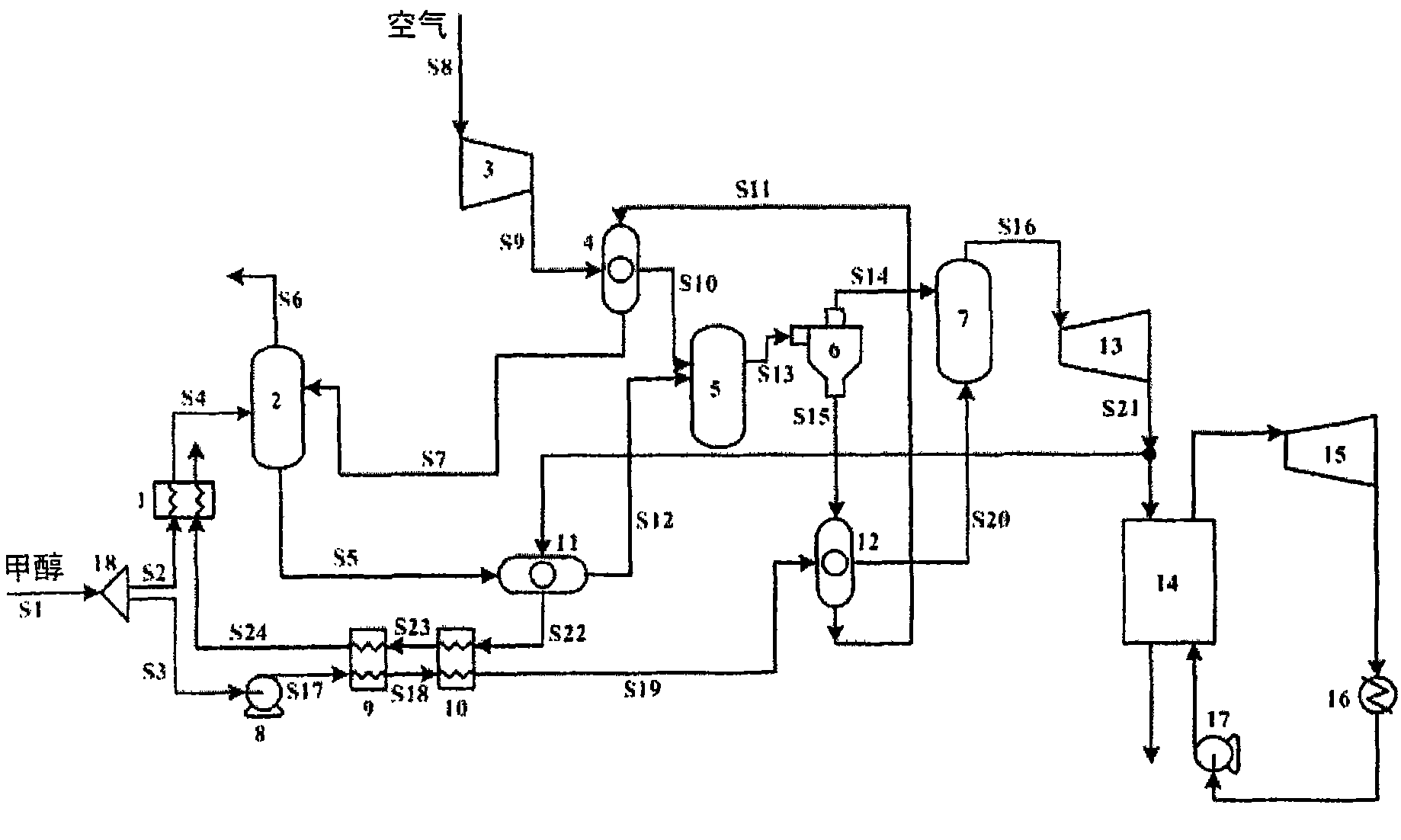

[0051] The present embodiment system consists of preheaters 1, 9, pumps 8, 17, gas-solid heat exchangers 4, 11, 12, splitter 18, reduction reactor 2, decomposition reactor 10, oxidation reactor 5, compressor 3 , cyclone separator 6, afterburning combustion chamber 7, gas turbine 13, waste heat boiler 14, steam turbine 15, and condenser 16. The specific process is:

[0052] Methanol S1 is divided into two streams S2 and S3 through the flow divider 18 and enters the system. Methanol S2 enters the reduction reactor 2 after being preheated by the preheater 1, and the preheating heat source is waste heat of flue gas. In the reduction reactor, methanol and Fe 2 o 3 The circulating particles S7 undergo a reduction reaction. After the reaction, methanol is oxidized to the gaseous product CO 2 and water vapor S6, Fe 2 o 3 is reduced to FeO solid particles S5, the reaction heat required by the circulating particles Fe 2 o 3 The sensible heat carried by itself is provided. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com