Patents

Literature

35results about How to "Raise initial temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

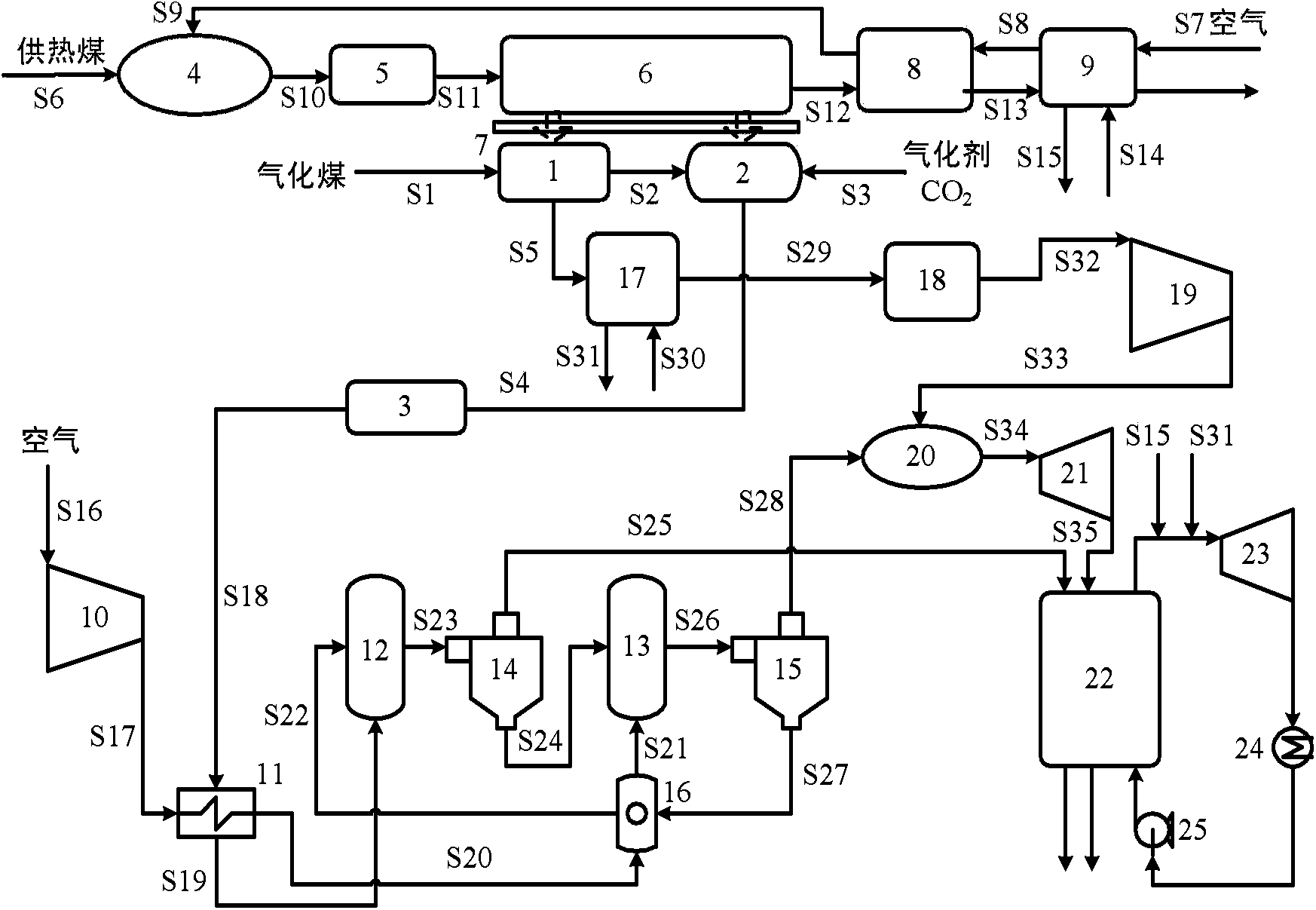

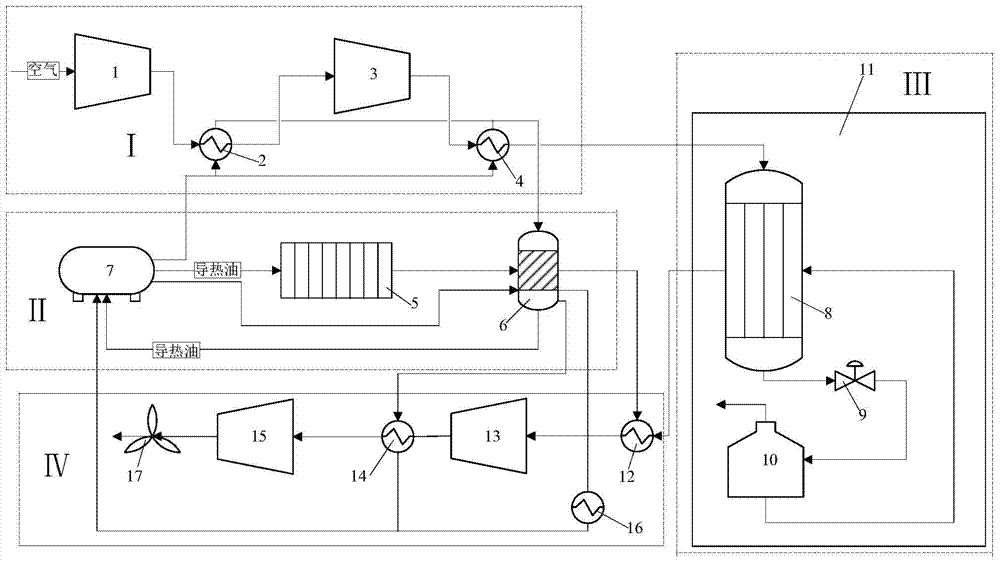

CO2 gas coke chemical-looping combustion power generating system and method

ActiveCN103758592ALess investmentReduce energy consumptionEnergy inputGas turbine plantsHydrogenWater vapor

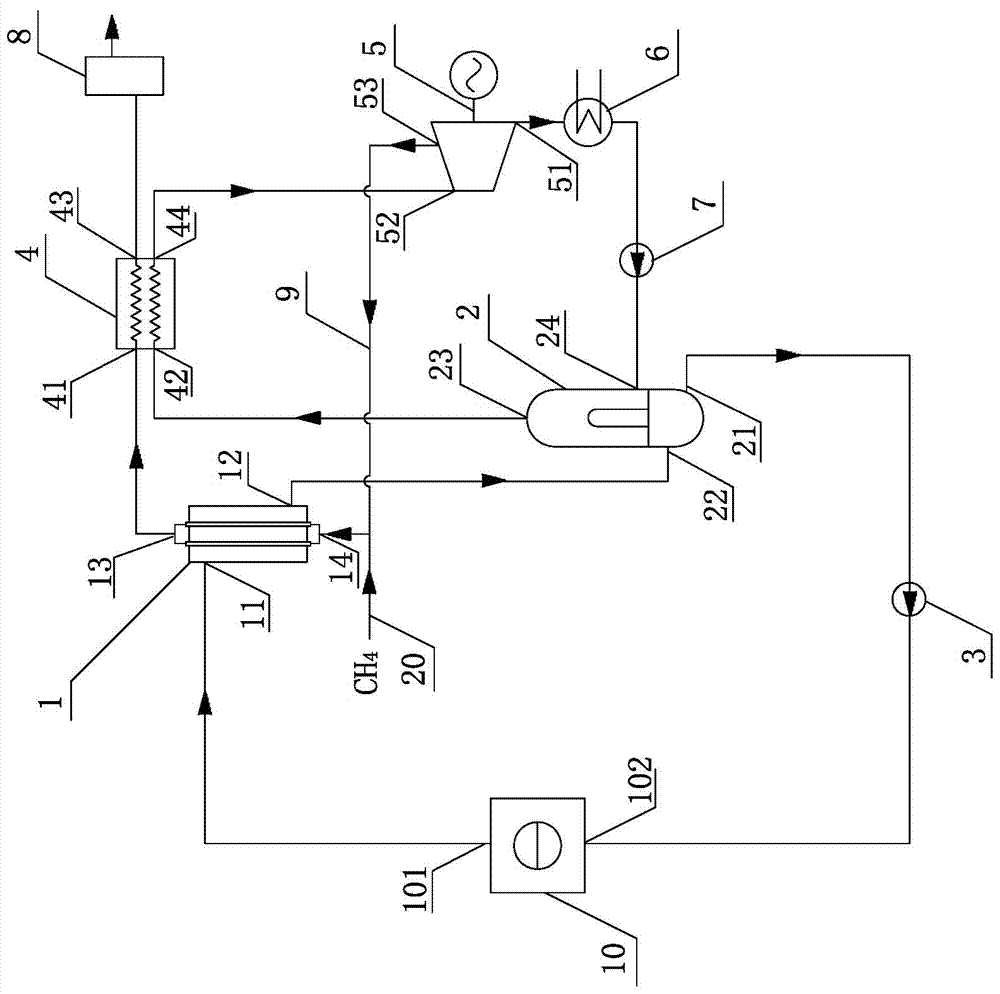

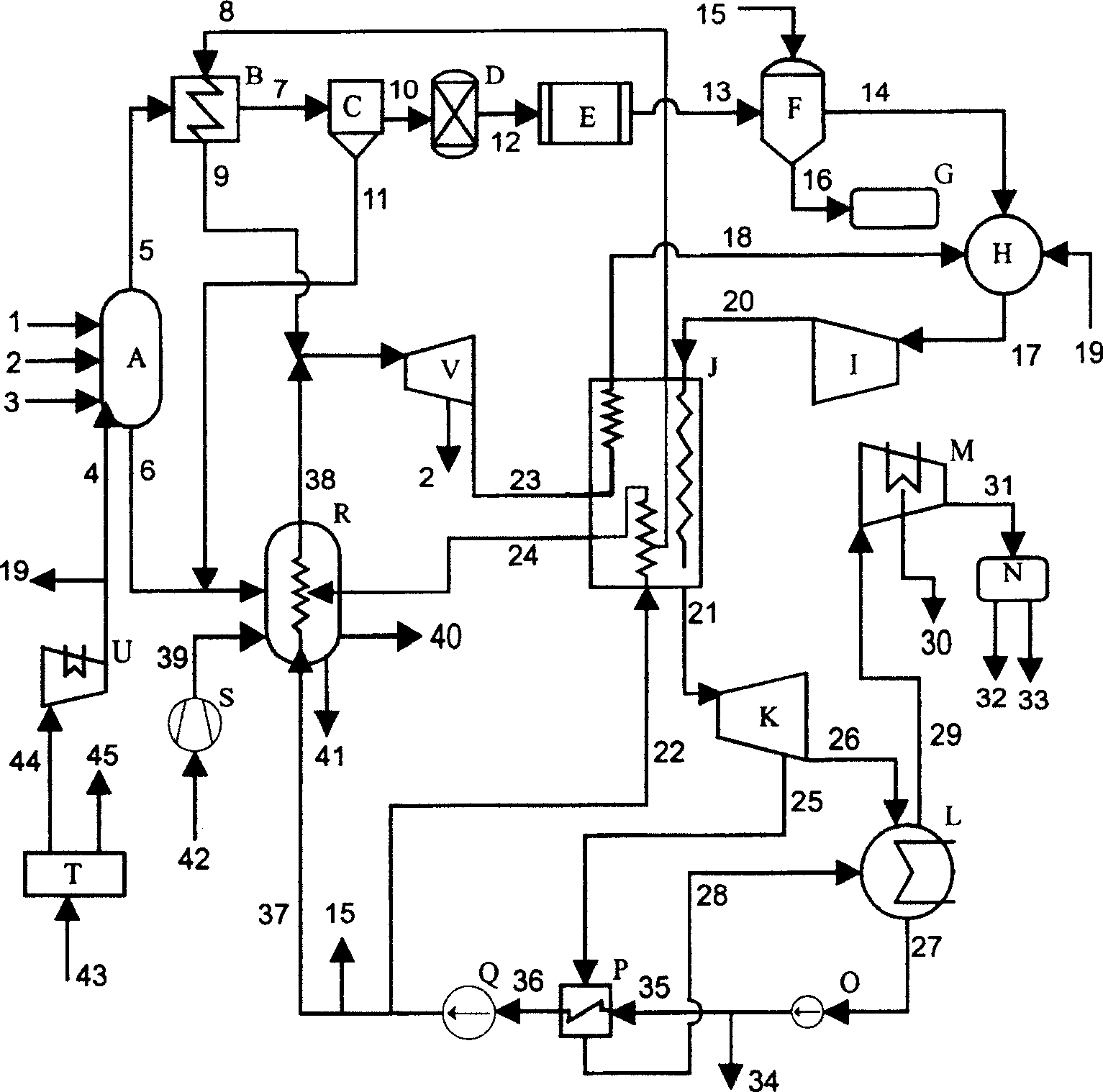

The invention discloses a CO2 gas coke chemical-looping combustion power generating system and method. The system comprises a coal step gasification subsystem, a fire coal heating subsystem, a chemical-looping combustion subsystem and a power generating subsystem. According to the system and method, coal to be gasified is partially gasified through the carbonization process, coke oven gas and coarse coke are generated, then the coarse coke reacts with CO2 to generate CO, and therefore step gasification of hydrogen and carbon components of the coal is realized, moreover, an expensive air separating unit is omitted, and the system energy consumption is lowered; through chemical-looping combustion of the CO, losses in the combustion process is reduced, and the efficiency of the system is improved; through afterburning of the coke oven gas, energy waste of the coke oven gas is avoided, the temperature of a fuel gas turbine inlet is lowered, and the problem that in a chemical-looping combustion power system, due to circulation material limitation, the primary temperature of a fuel gas turbine inlet is low is solved. Due to the fact that CO2 generated in a chemical-looping combustion reduction reactor is not diluted by N2, CO2 zero-energy-consumption separation can be realized by removing steam through simple condensing.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

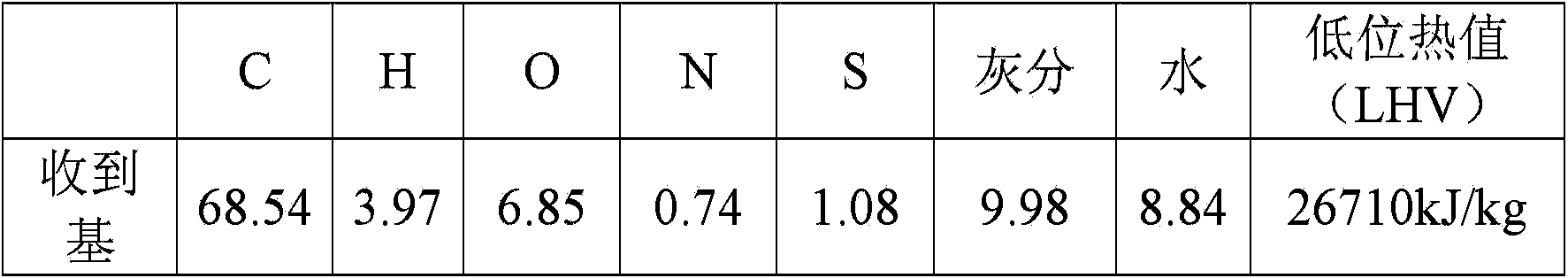

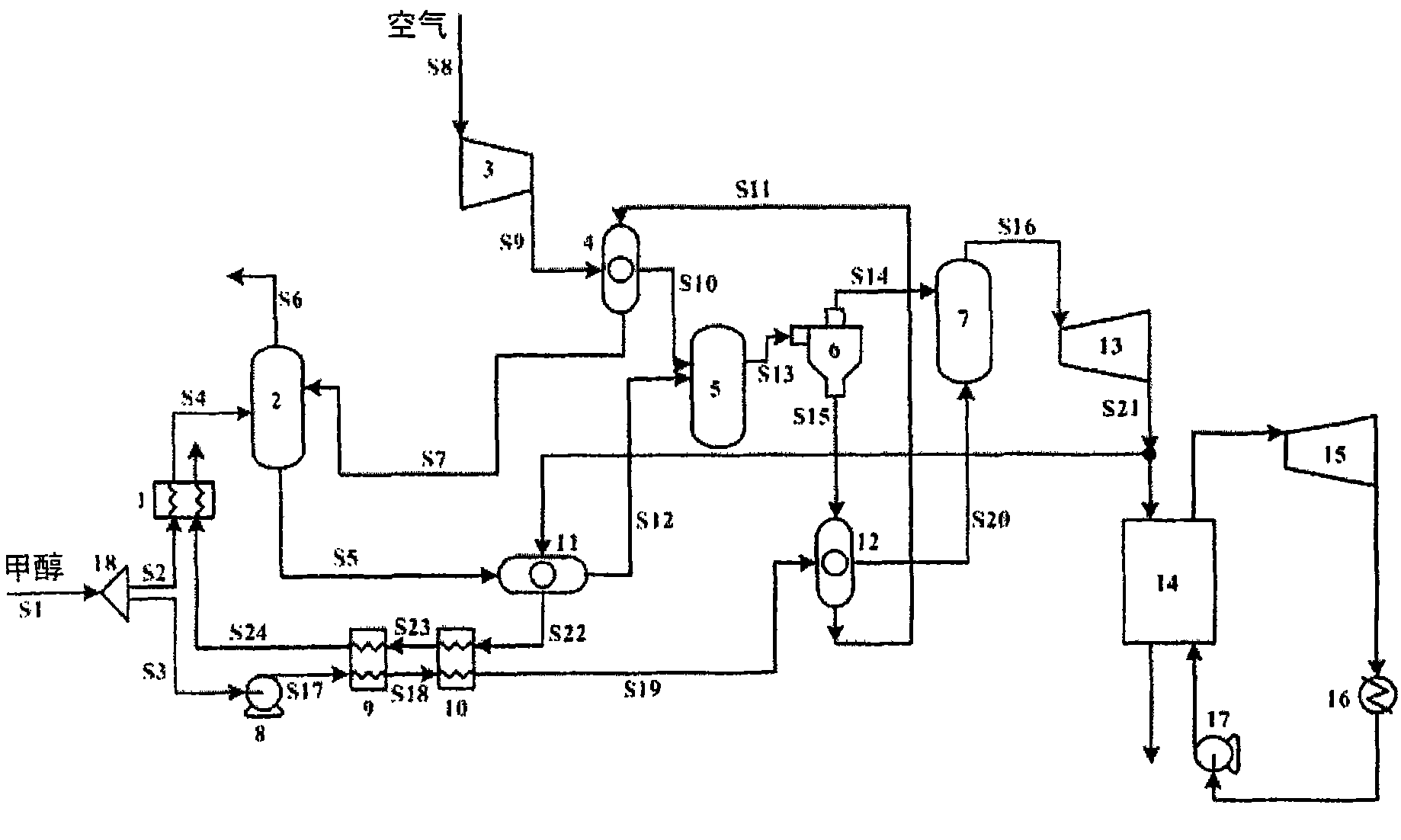

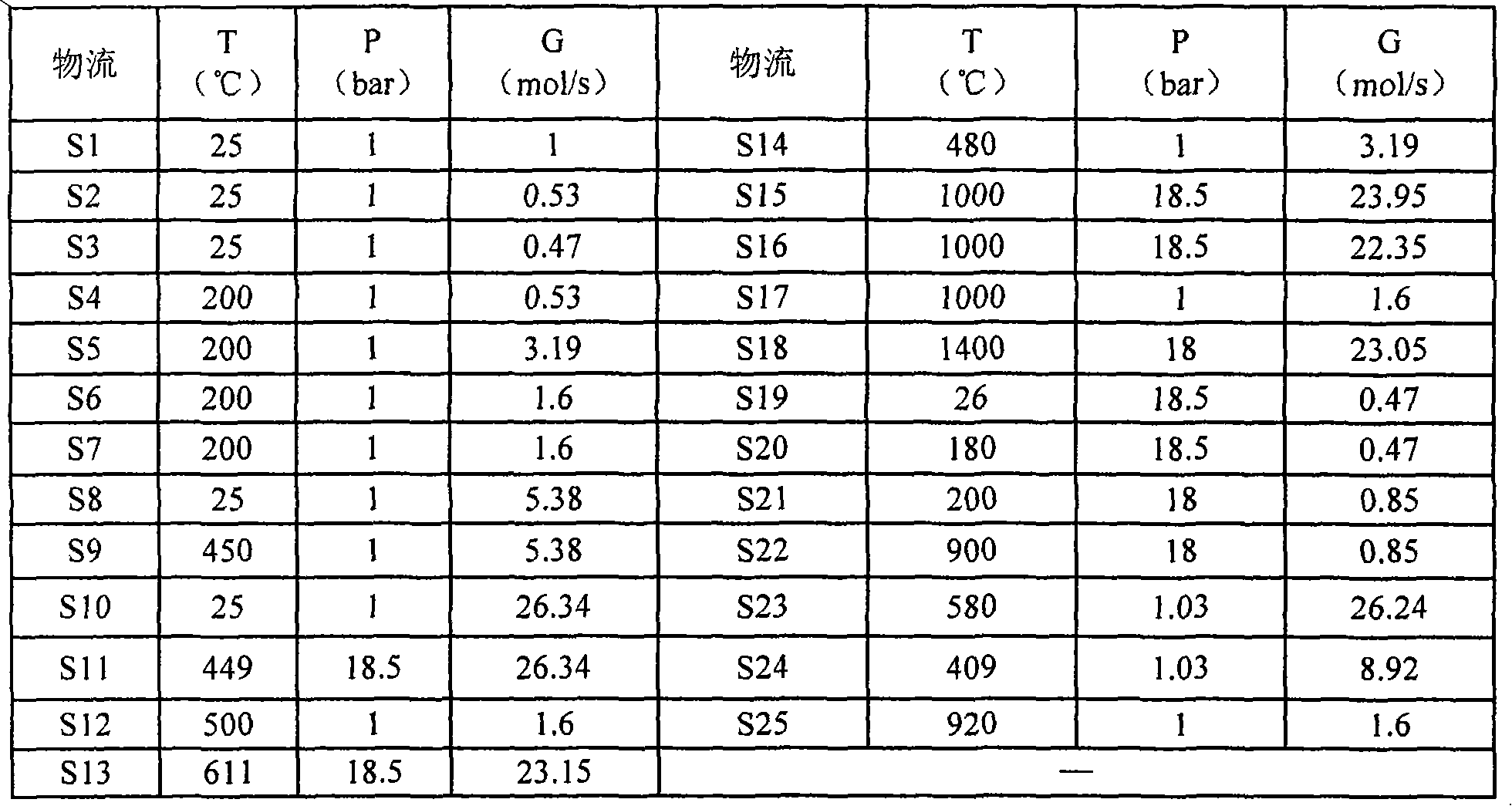

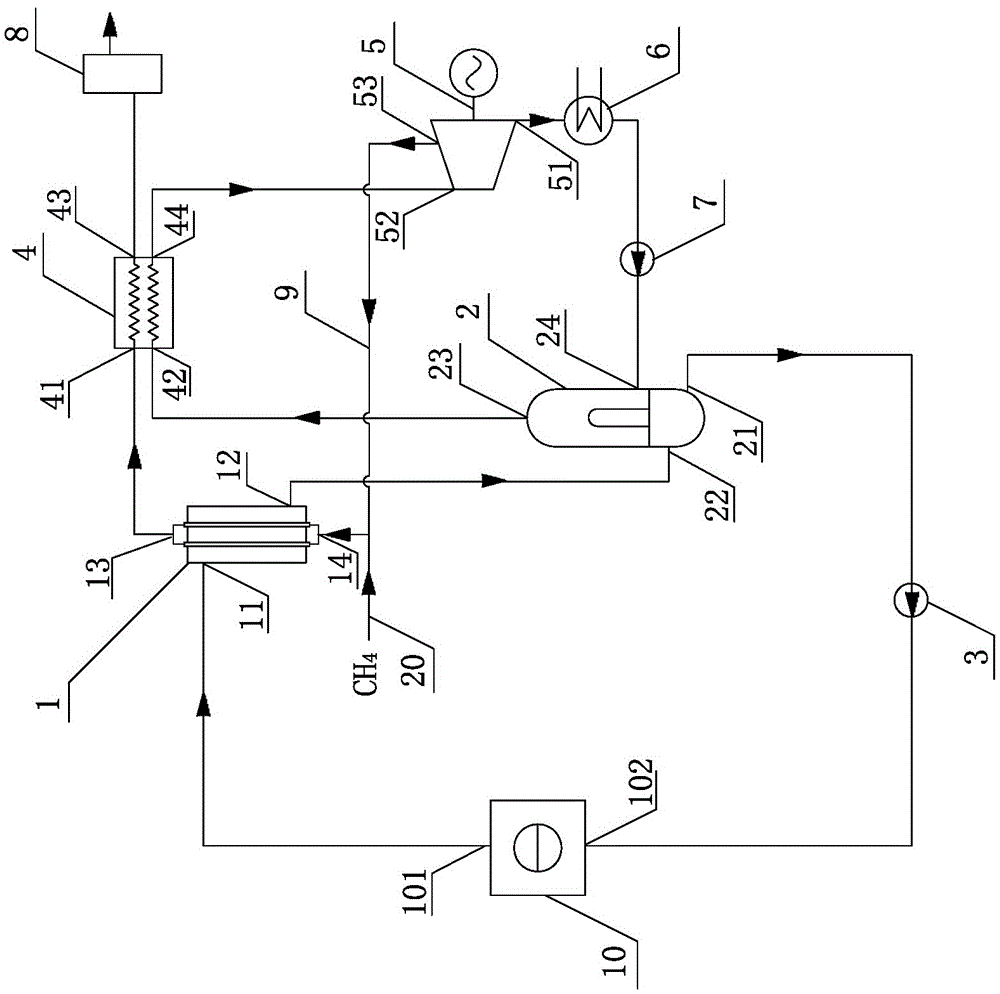

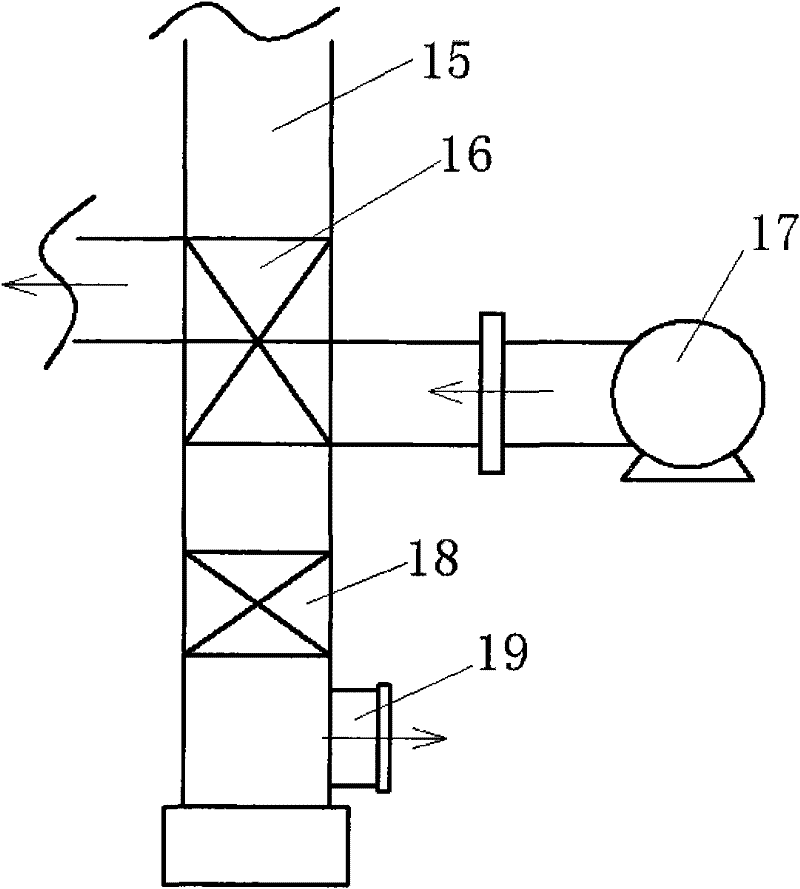

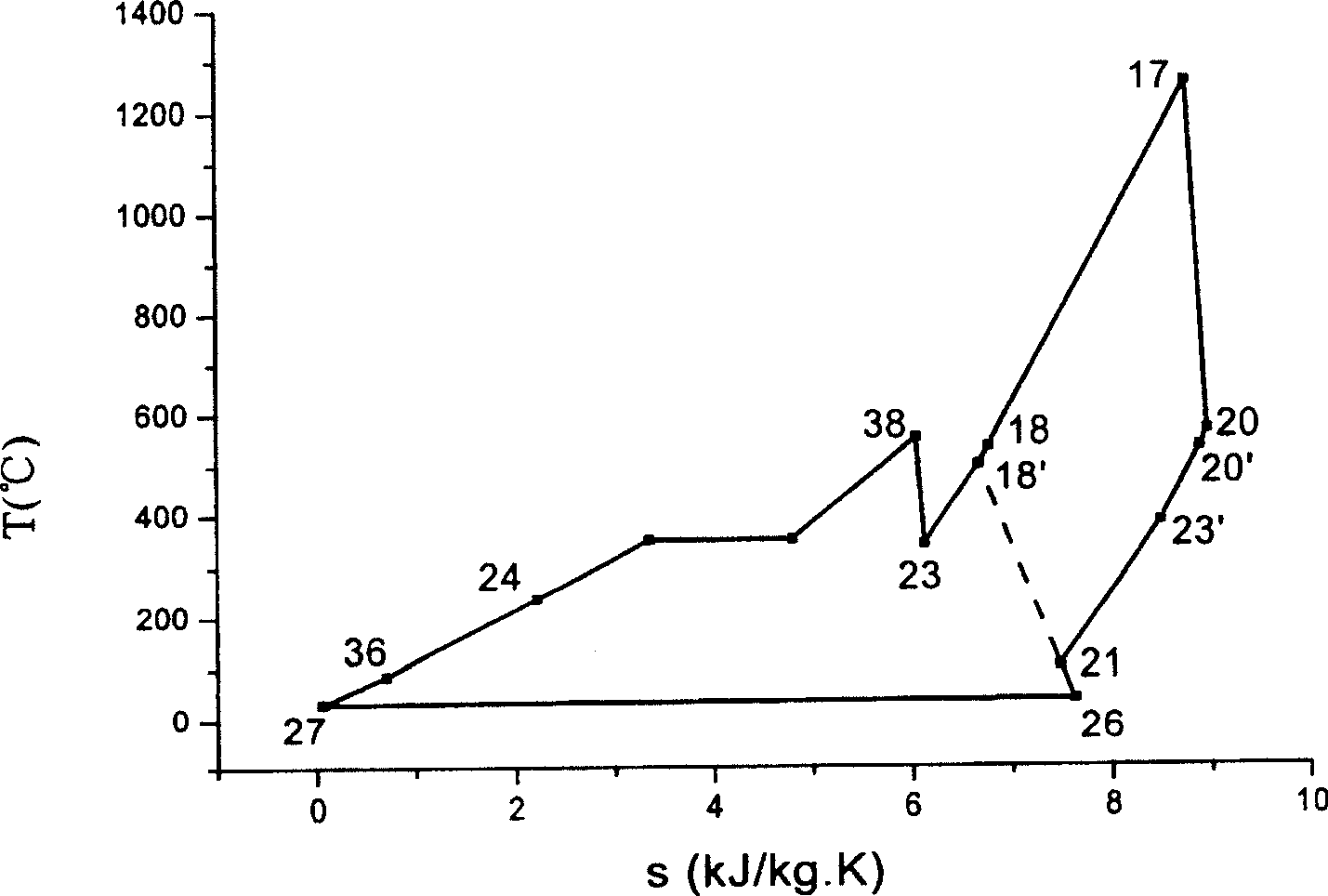

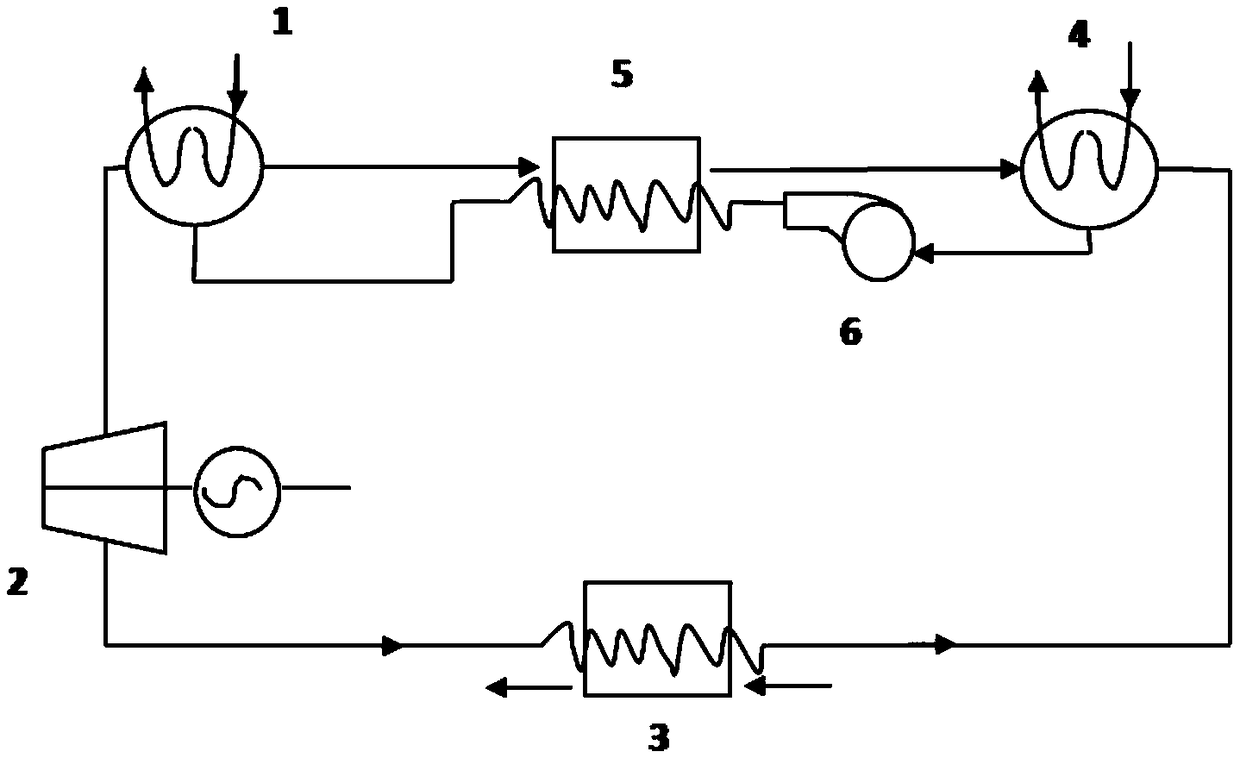

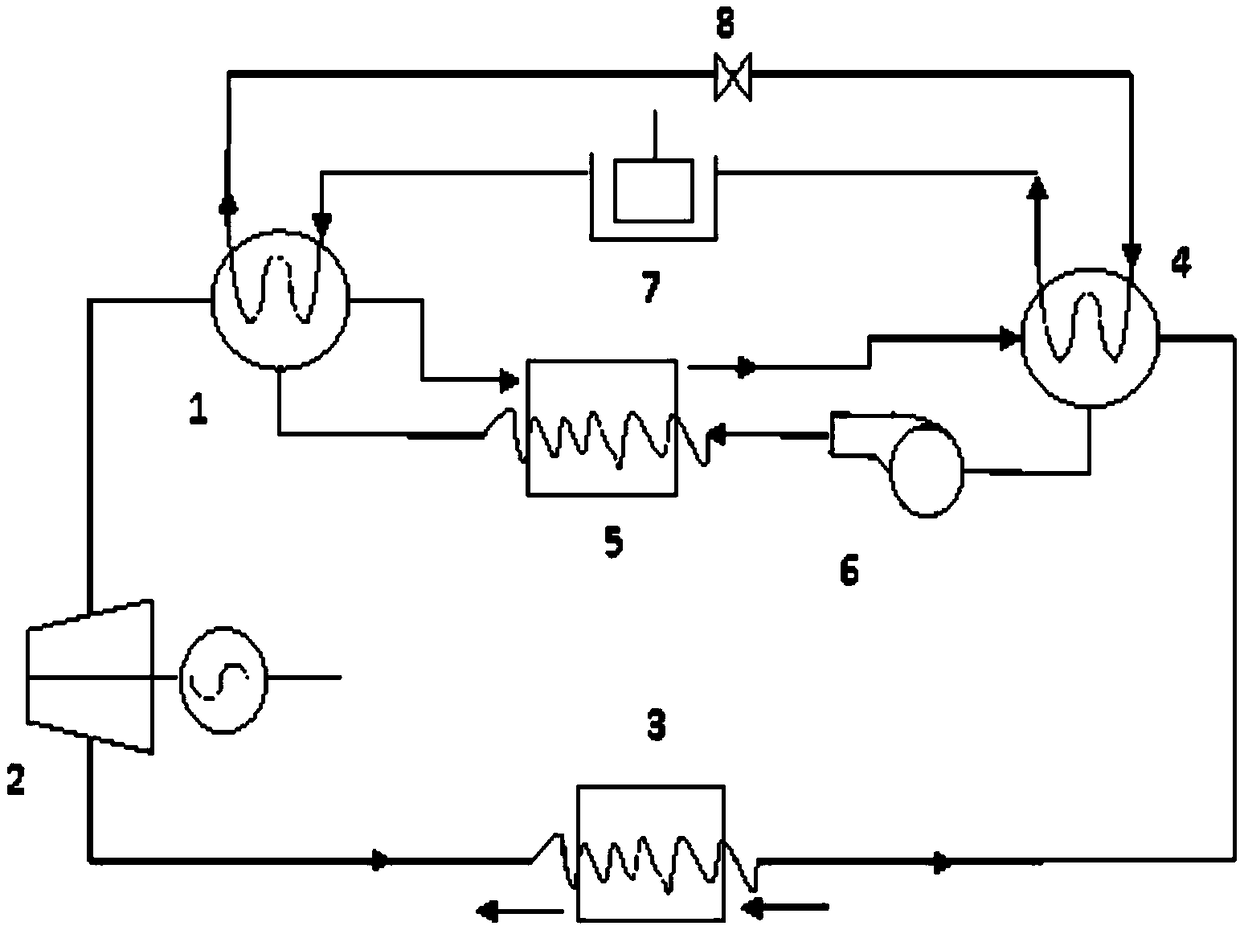

Solar energy and methanol fuel chemical-looping combustion power generation system and method

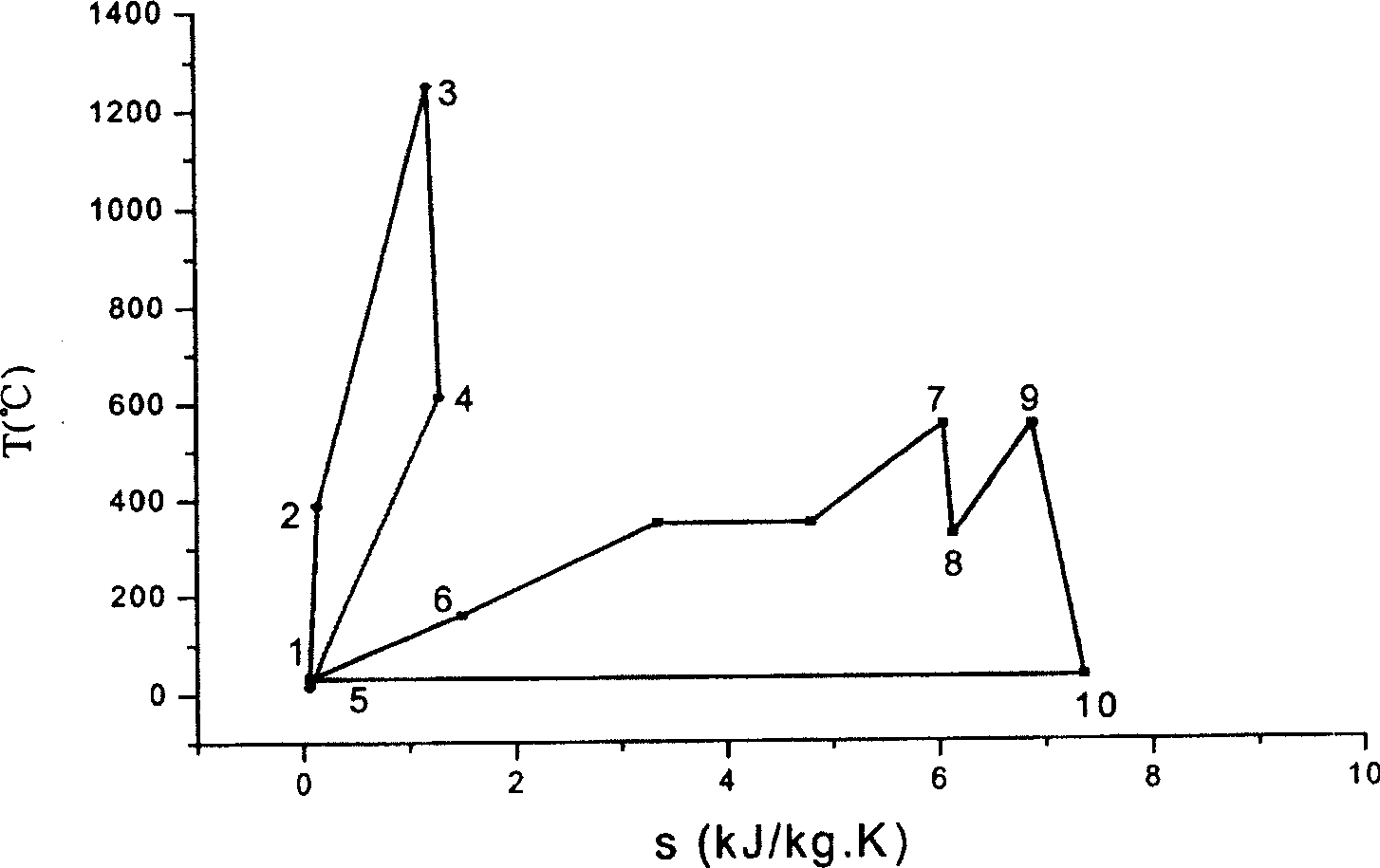

ActiveCN101888194ARealize cascade utilizationOvercoming the problem of low initial temperatureSteam engine plantsLight radiation electric generatorCombustion chamberChemical reaction

The invention relates to the technical fields of the solar thermal power generation and energy, in particular to a solar energy and methanol fuel chemical-looping combustion power generation system and method used for controlling CO2 emission. The intermediate-low temperature solar thermochemical process and the chemical-looping combustion power cycle are coupled organically to form the system ofthe invention. The system comprises a solar heat collecting-reduction reactor, a solar heat collecting-decomposition reactor, an oxidation reactor, an afterburning combustion chamber, a gas turbine, a steam turbine, an exhaust-heat boiler, a heat exchanger and the like. By using the device of the invention, the graded use of energy resources with different qualities can be realized; the zero-energy separation of CO2 can be realized through simple condensation; the combustion method can reduce the fuel grade to FeO grade, thus reducing the fuel loss in the combustion process and increasing theefficiency of the system; the solar thermochemical reaction is adopted to improve the grade of intermediate-low temperature solar energy; and afterburning is adopted so as to solve the problem that the gas turbine inlet has low initial temperature caused by the limit of the cycle material in the chemical-looping combustion power system.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

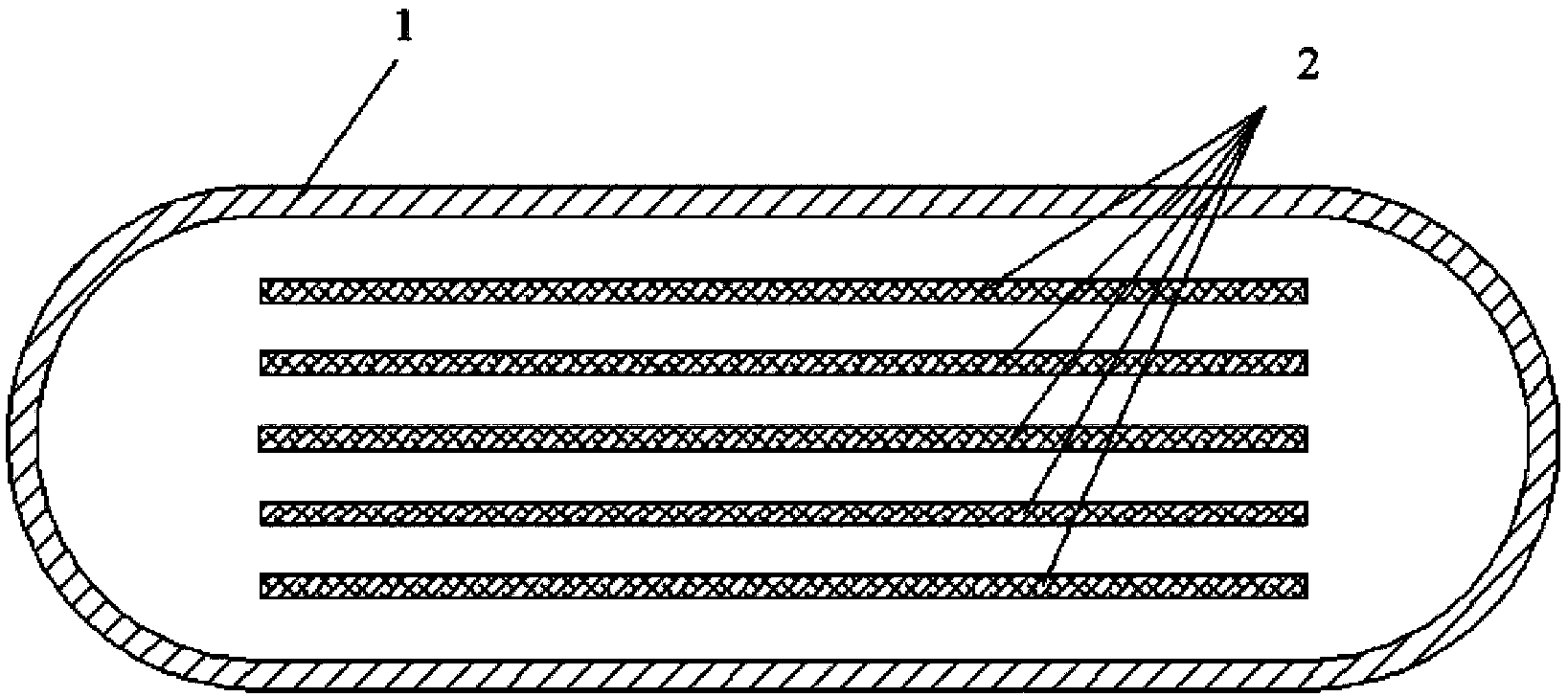

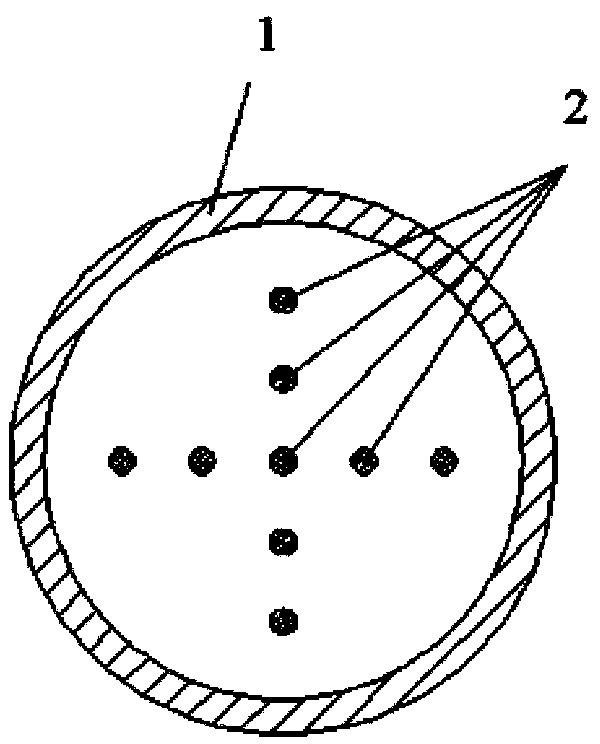

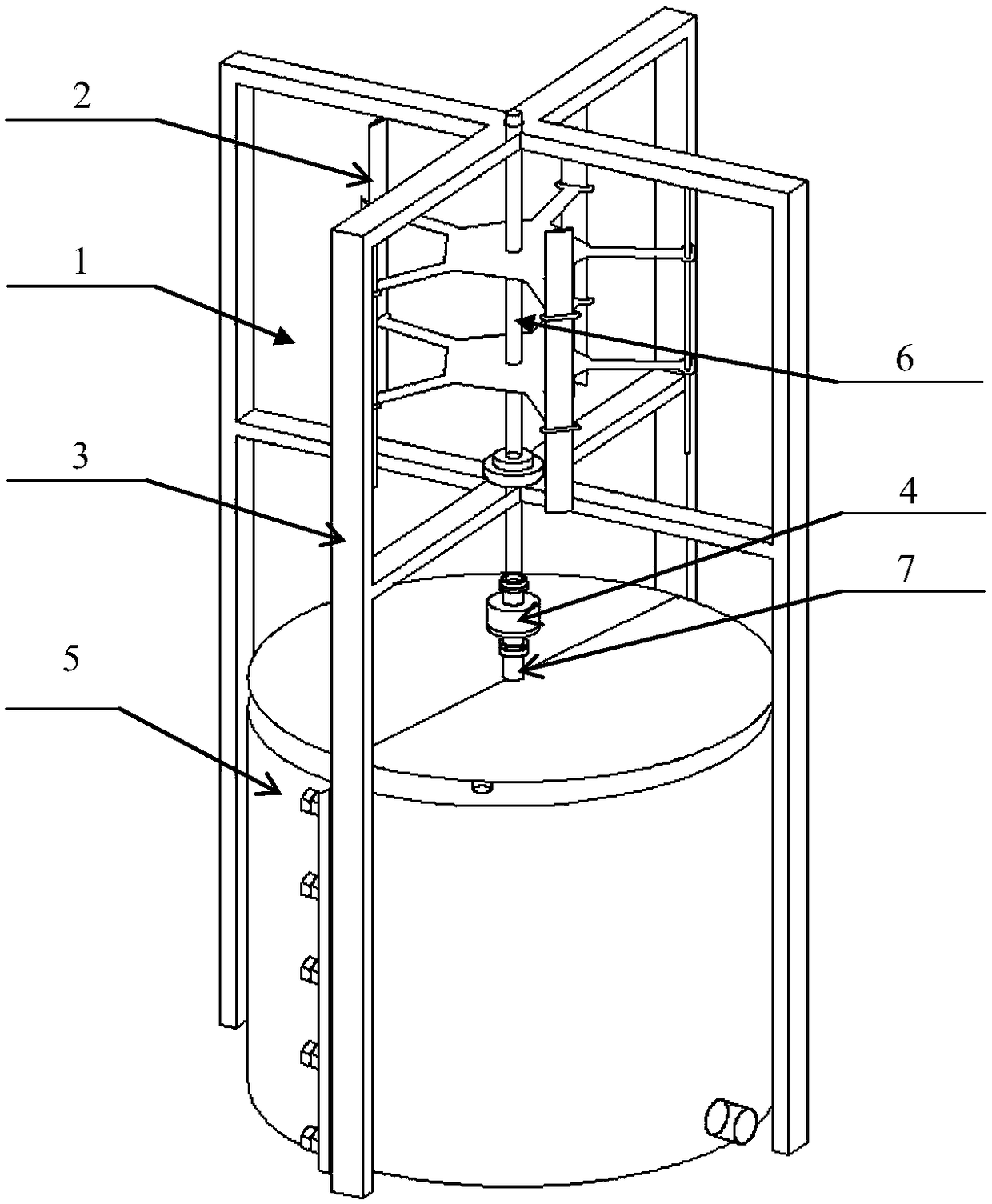

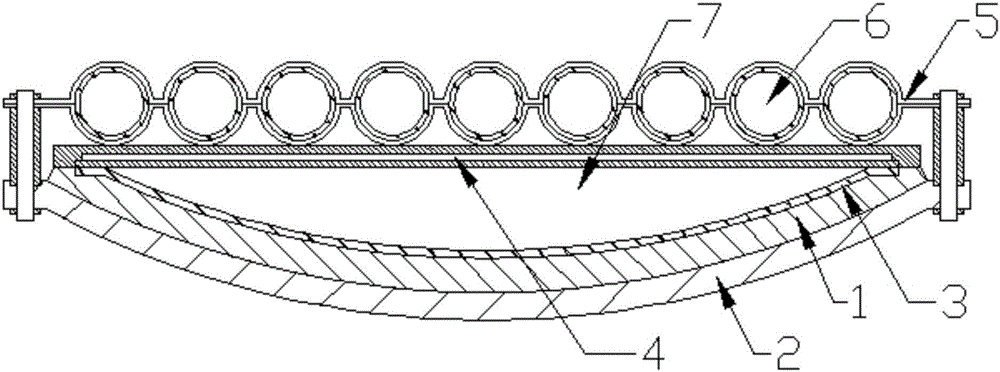

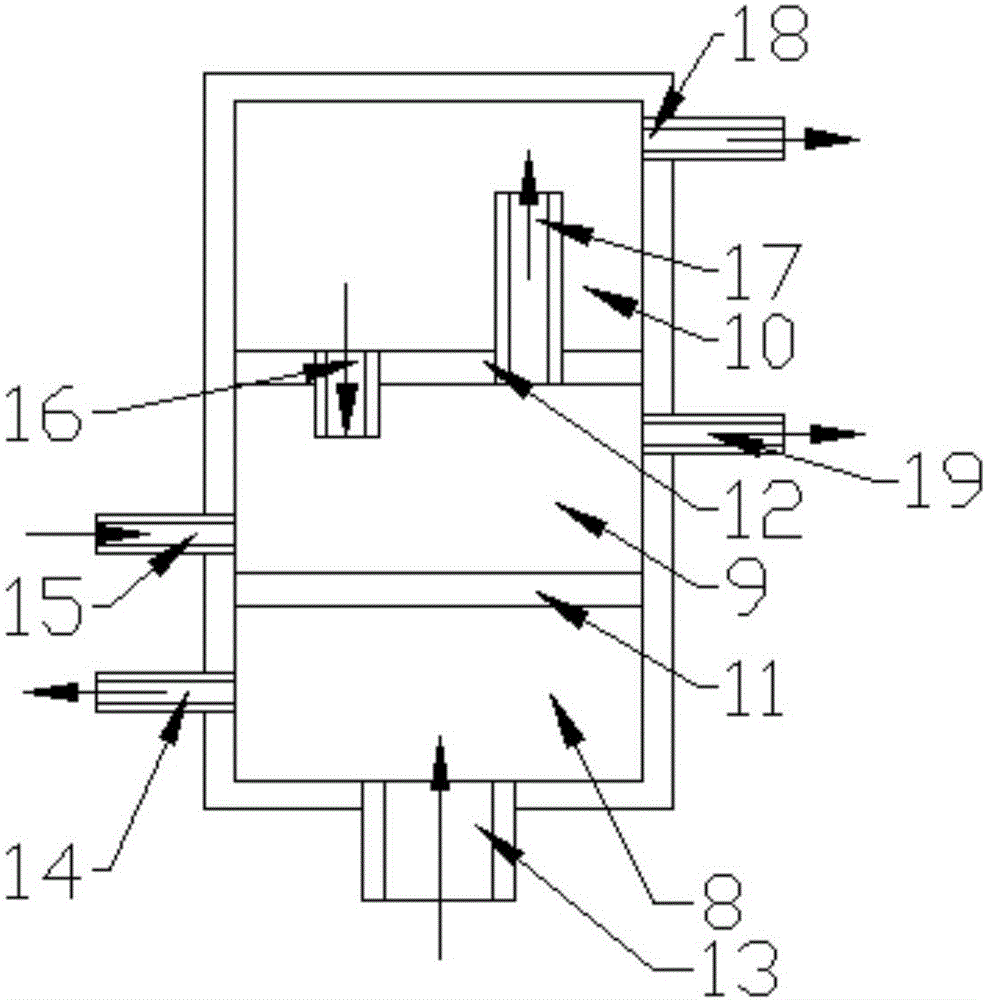

Constant-temperature air storage system applied to compressed air energy storage power generation system

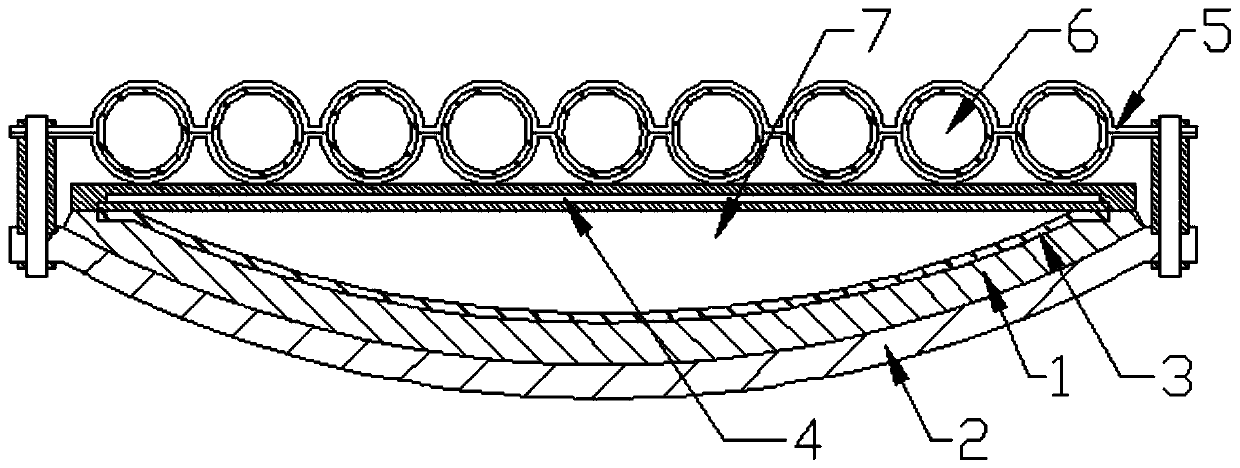

InactiveCN103353060AReduce dissipationLow costContainer filling methodsPressure vesselsEngineeringPhase change

The invention relates to the field of compressed air energy storage power generation and particularly relates to a constant-temperature air storage system applied to a compressed air energy storage power generation system. The constant-temperature air storage system comprises an air storage device 1 and a heat storage device 2 arranged in the air storage device, wherein the heat storage device 2 is a heat storage working medium; the required heat storage working medium is a phase change heat storage working medium or the heat storage working medium with the specific heat capacity more than 0.5 kJ / kgk or a combination of the phase change heat storage working medium and the heat storage working medium. The constant-temperature air storage system has the following advantages: firstly, the air storage device can adopt a cheaper steel and iron material, so that the adoption of a more expensive low-temperature-resistant material is avoided and the cost is saved; secondly, heat stored in a high-efficiency heat storage device in an air bleeding process can be used for heating air in the air storage device, so that the primary temperature of the air entering a turbo expander is increased, the work applying capability of the air is improved, and the energy storage efficiency of the system is improved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

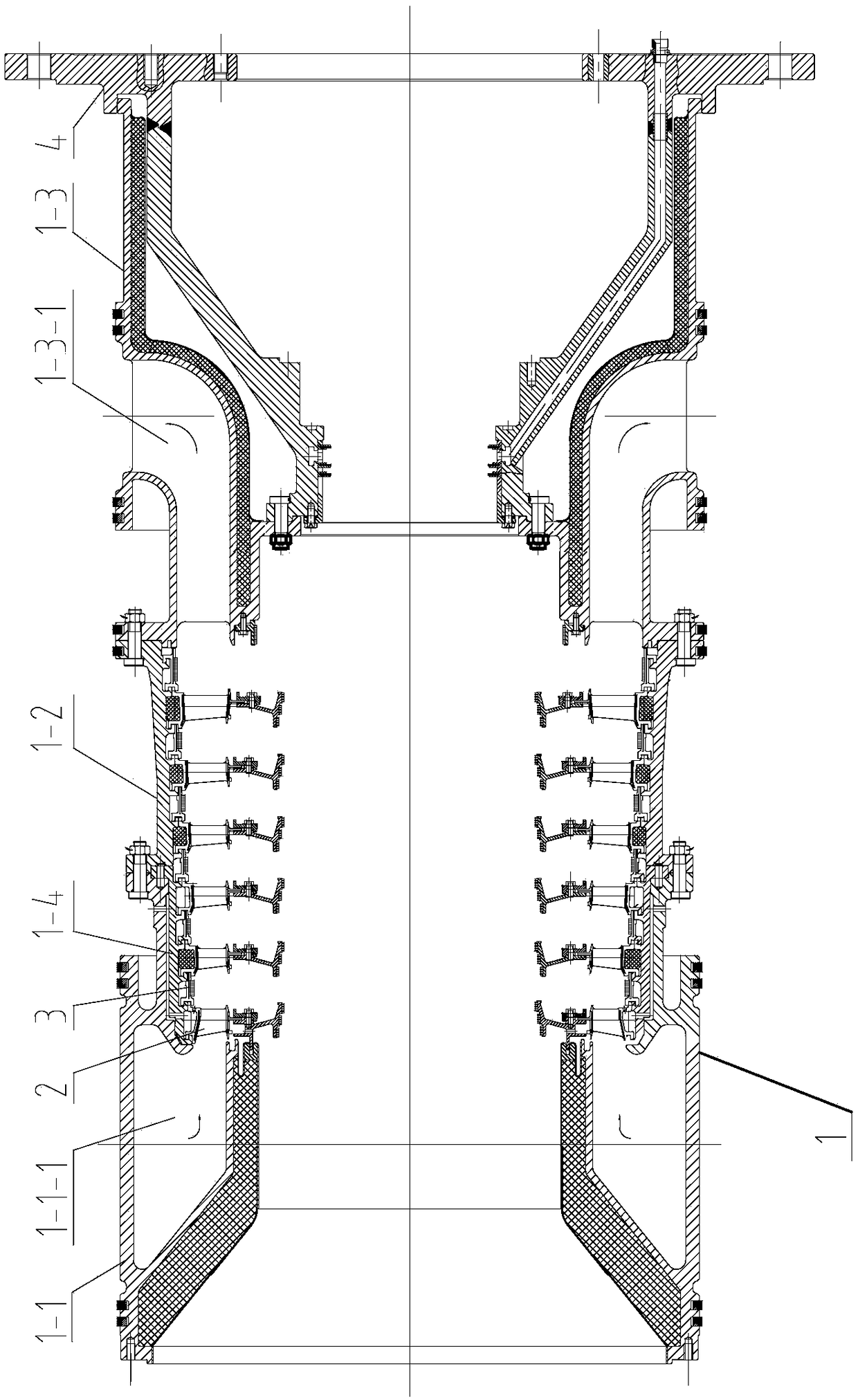

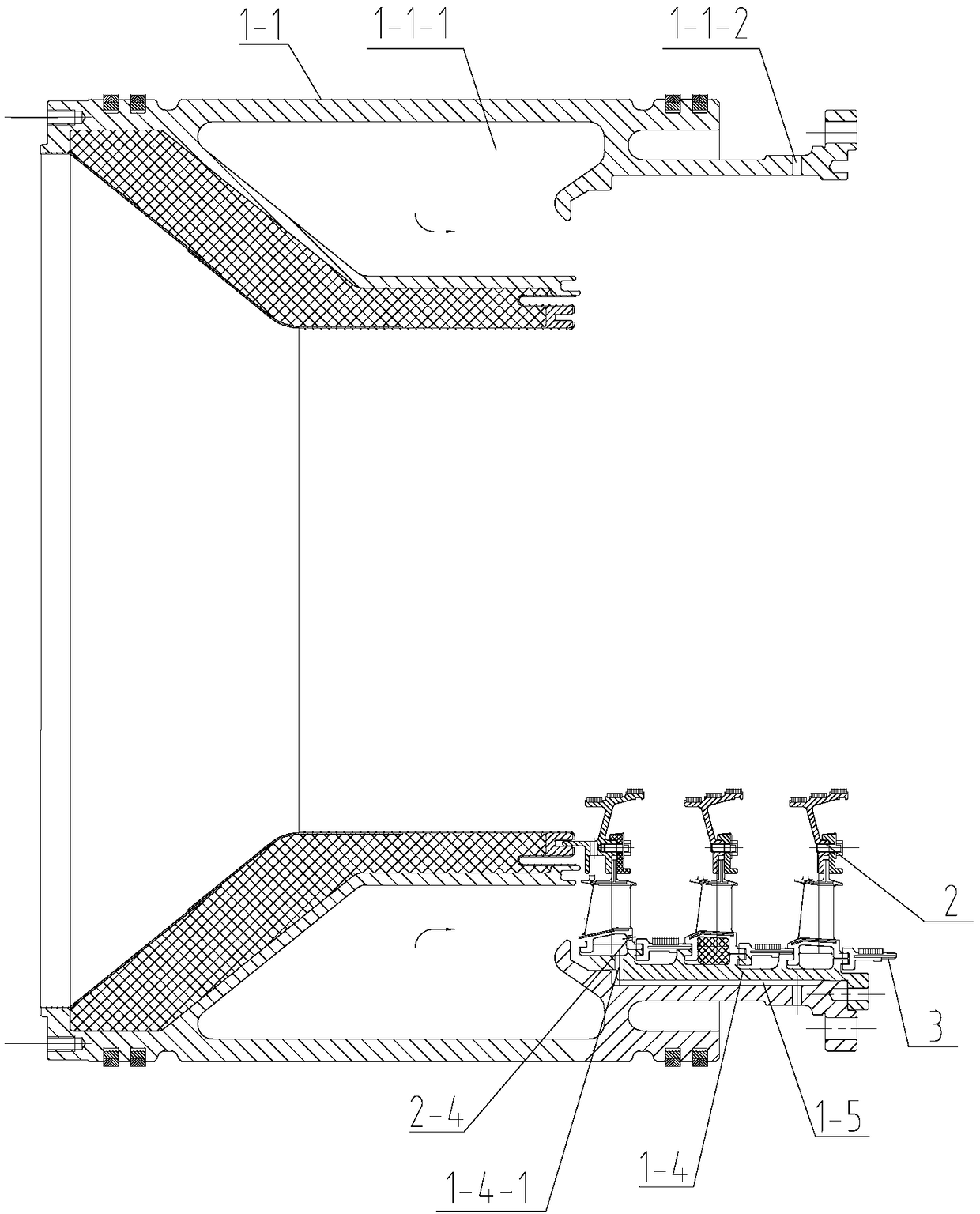

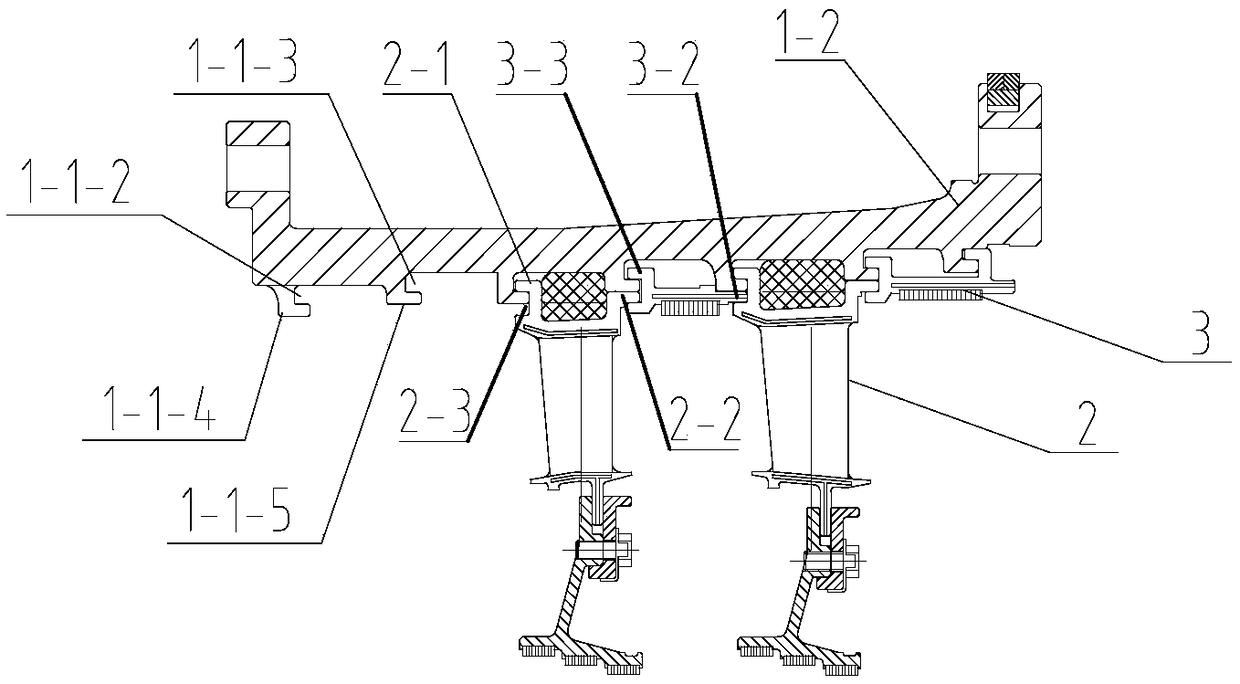

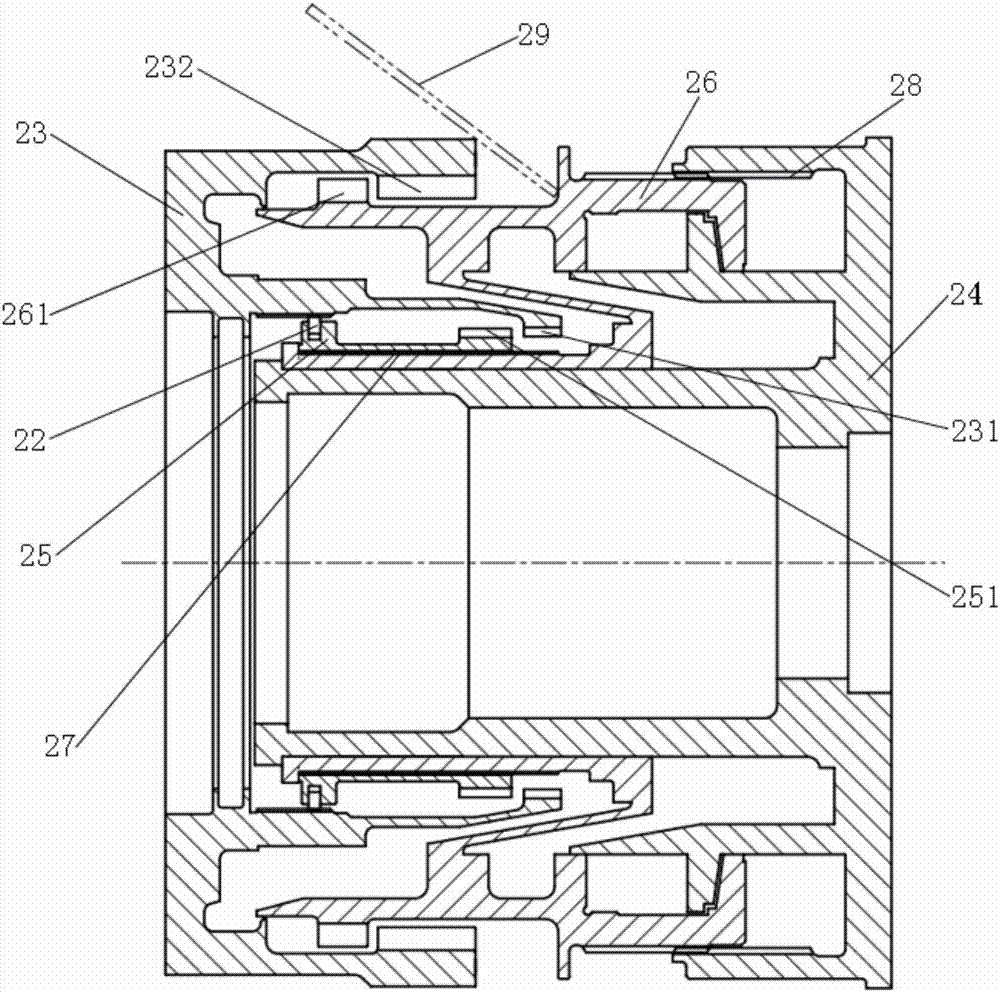

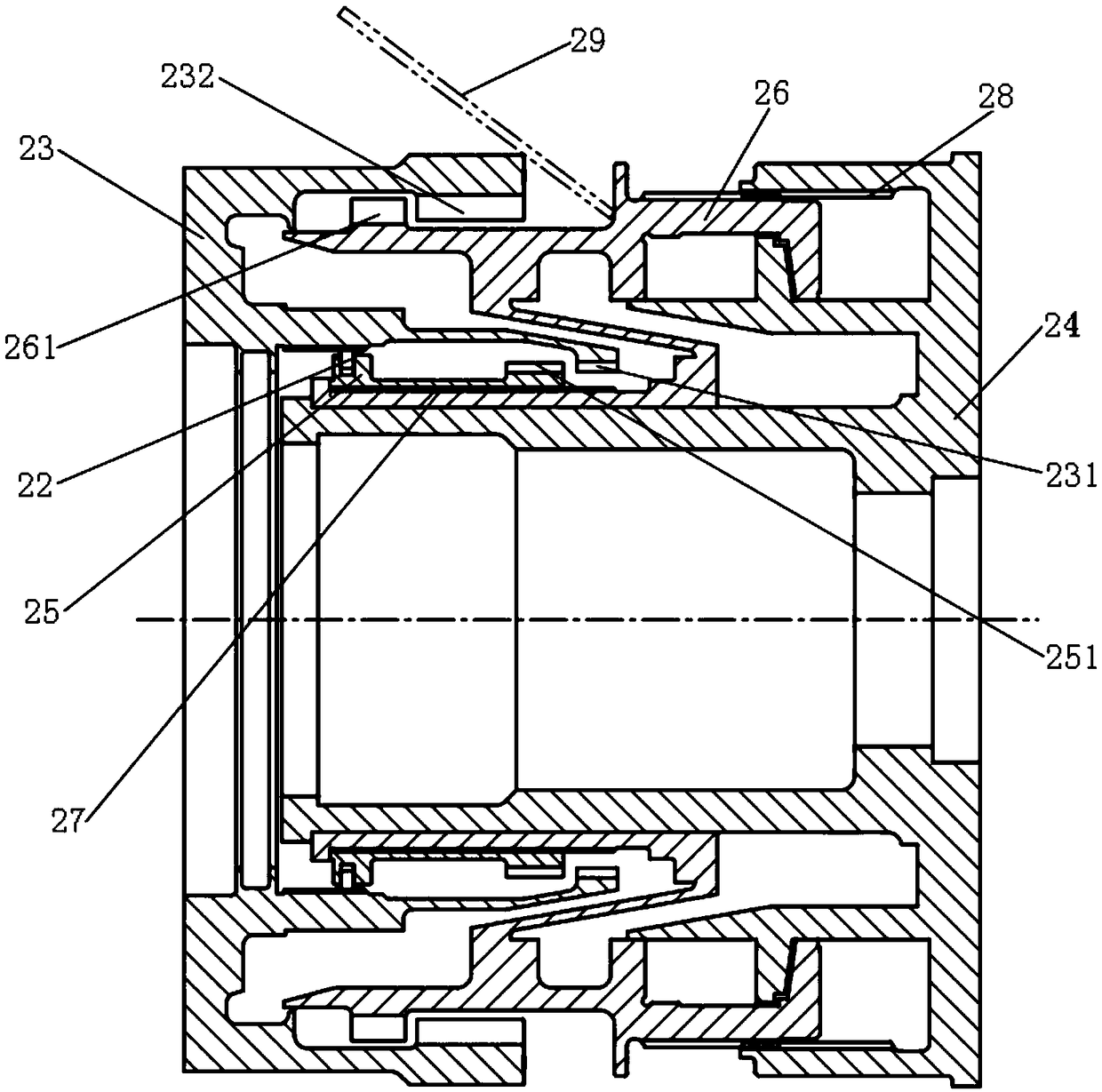

Turbine stator structure for helium turbine

PendingCN109057877AImprove work efficiencySmall structureStatorsMachines/enginesNuclear reactorTurbine blade

The invention provides a turbine stator structure for a helium turbine, relates to the field of turbines, and solves the problems that when a conventional turbine is applied to a nuclear reactor, an entire turbine case is integrated and inconvenient to dismount and mount, an entire turbine stator structure is too long, and the helium work efficiency is low. The turbine stator structure comprises agas intake machine case, a turbine case, a gas exhauster case, guides, sealing rings and a bearing shell, wherein a flange at the rear end of the gas intake machine case and a flange at the front endof the turbine case are in bolted connection with each other; a flange at the rear end of the turbine case and a flange at the front end of the gas exhauster case are in bolted connection with each other; a flange at the front end of the bearing shell and a flange at a position above the inner middle of the gas exhauster case are in bolted connection with each other; the rear end of the gas exhauster case is inserted into a clamping slot at the tail of the bearing shell; and the guide groups of six grades and the sealing rings of six grades are sequentially mounted in the gas exhauster case and the clamping slot of the gas exhauster case one by one. The turbine stator structure provided by the invention is applied to the helium turbine.

Owner:中国船舶重工集团公司第七0三研究所

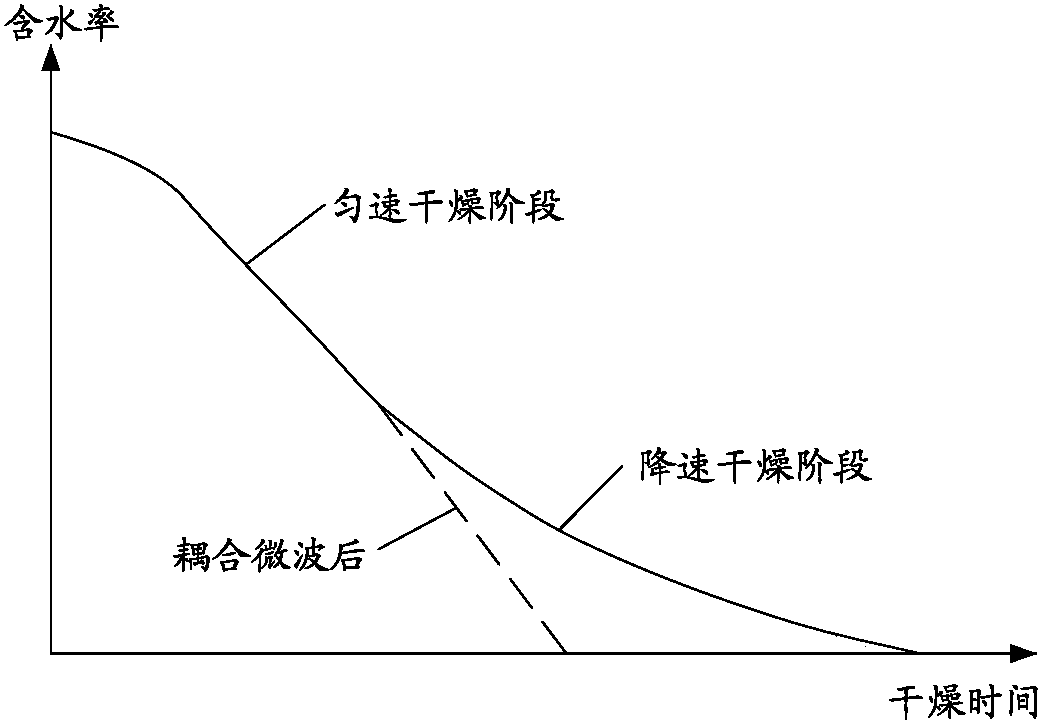

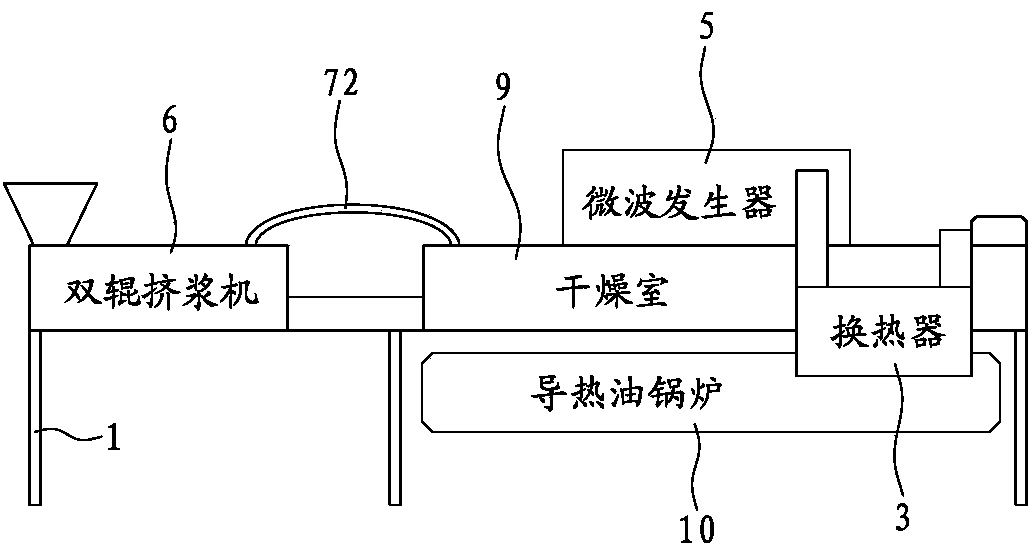

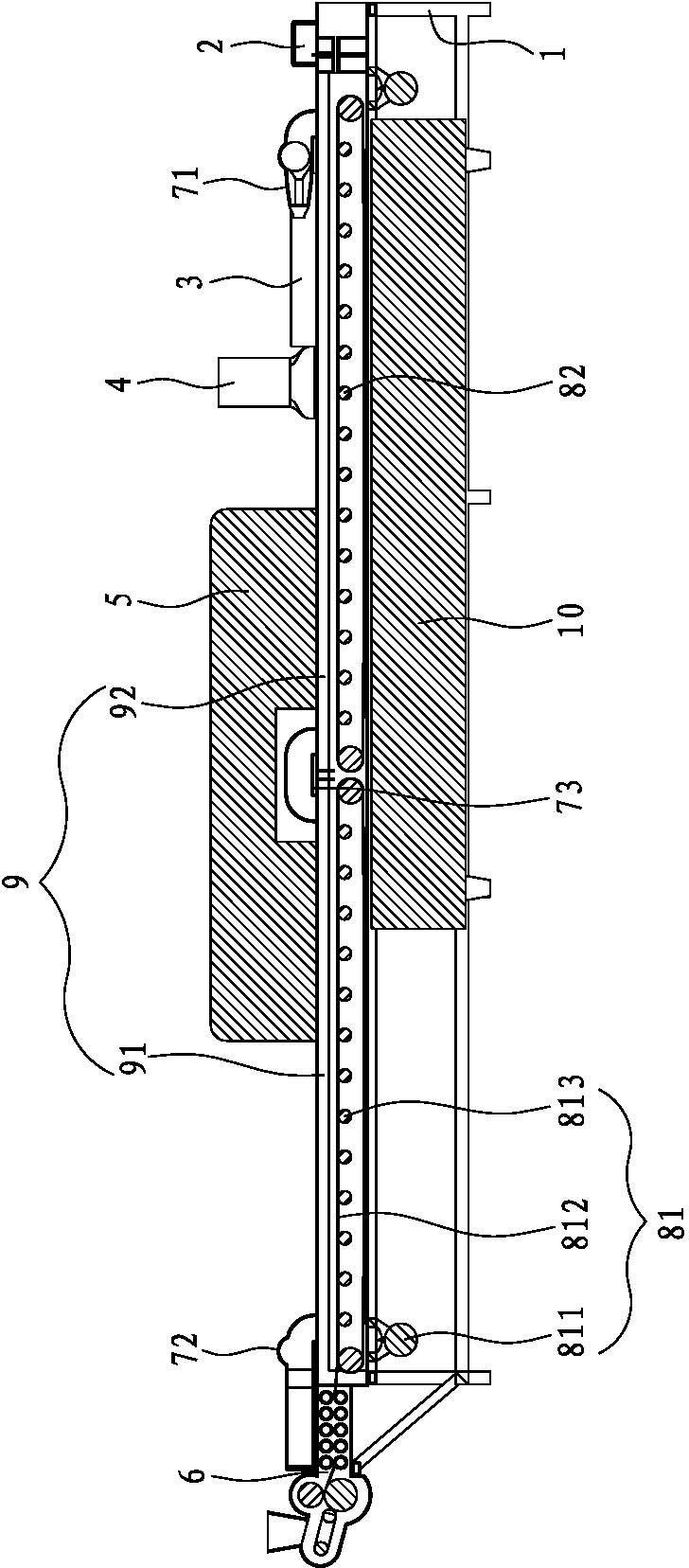

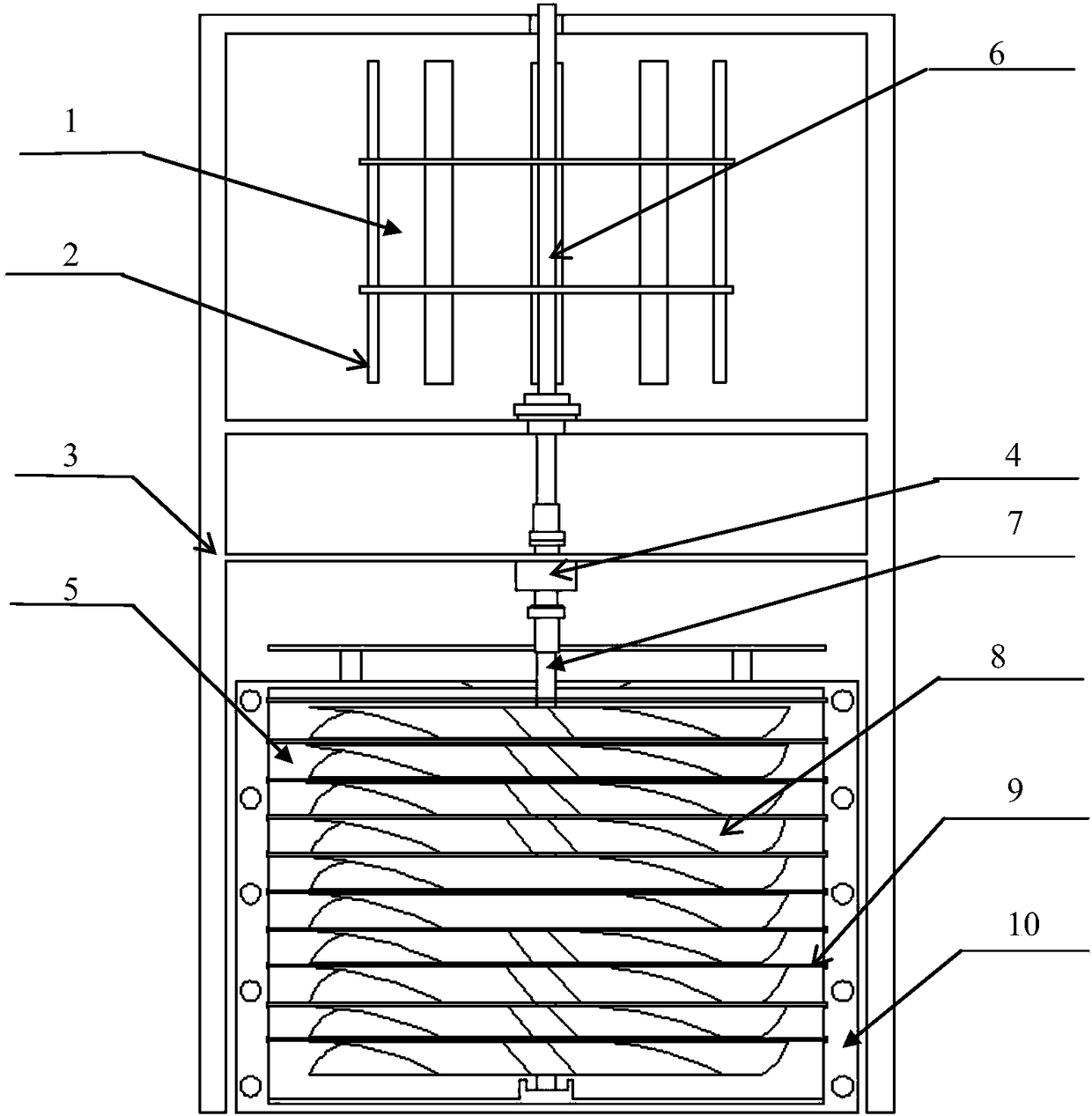

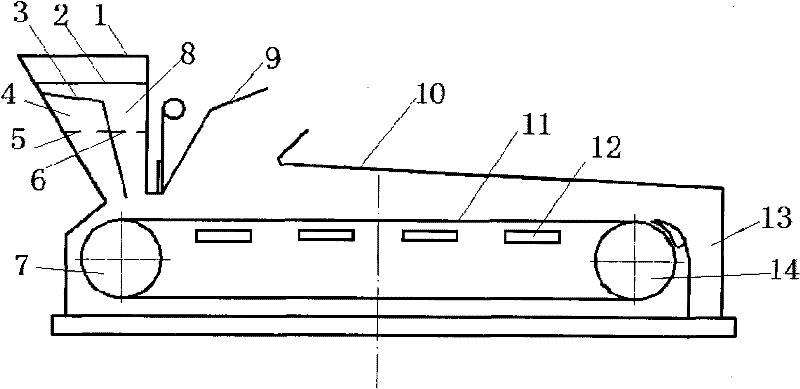

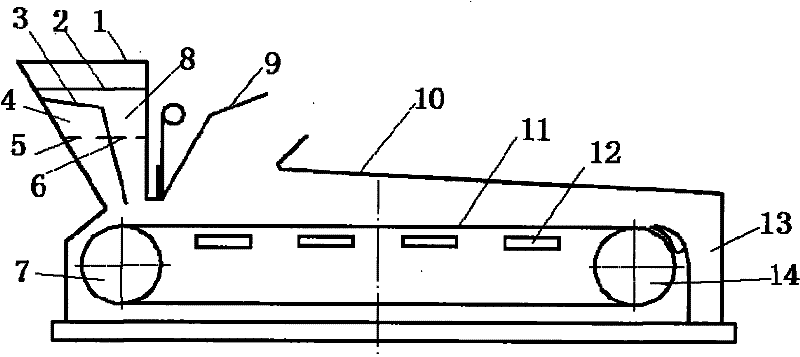

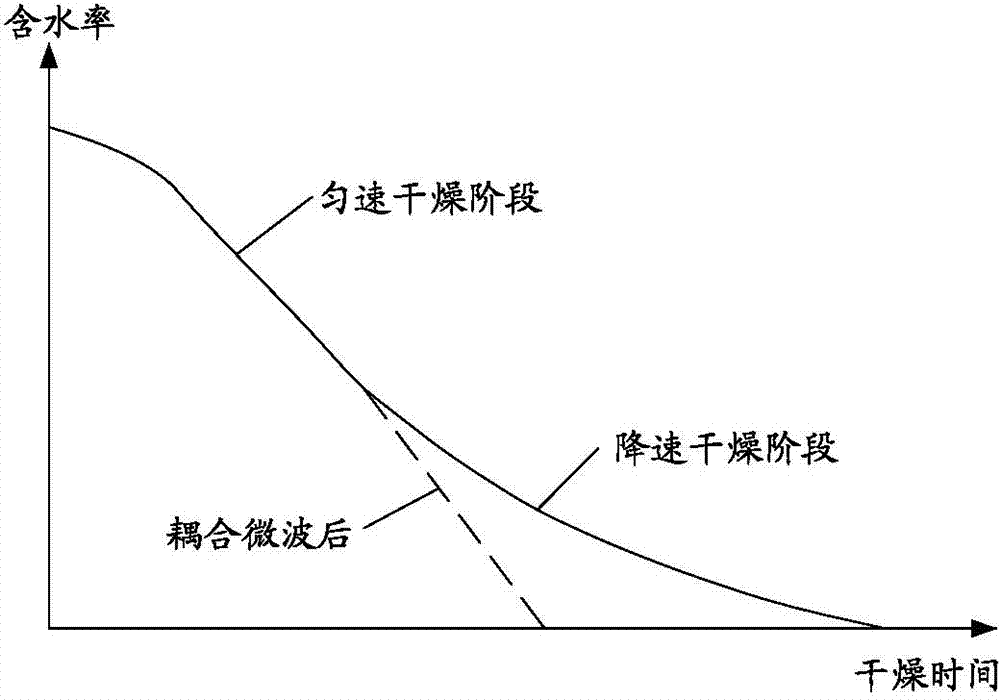

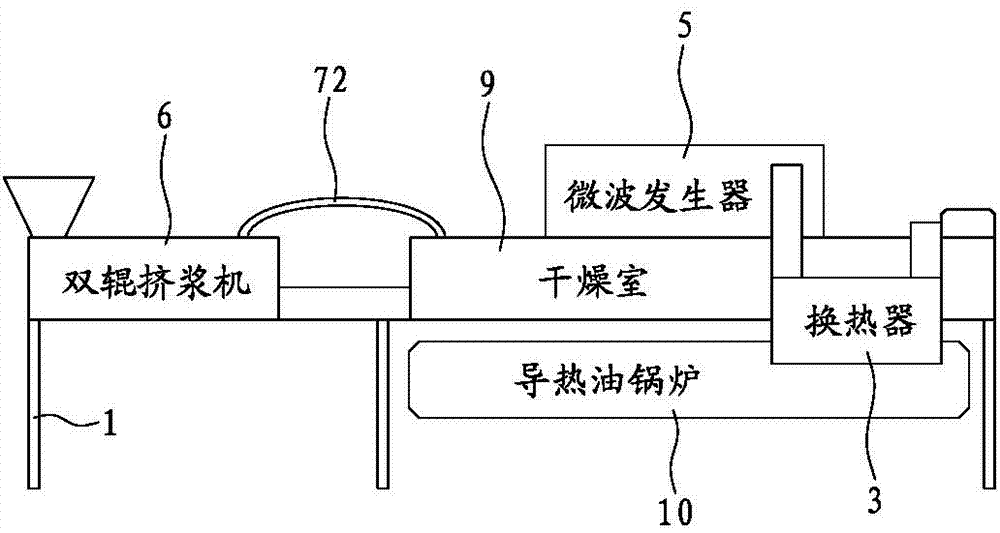

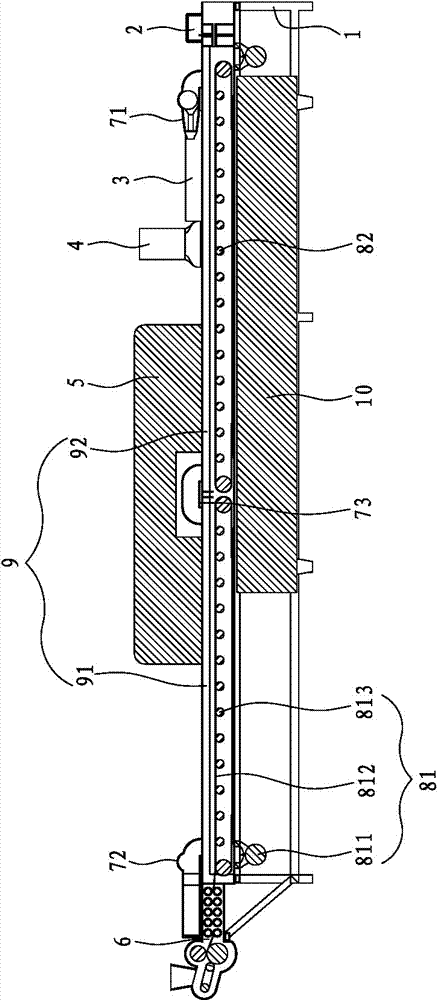

Efficient energy-saving pulp dewatering and drying equipment

ActiveCN103438678AReduce drying costsLow costPulp de-wateringDrying gas arrangementsAir preheaterMicrowave

The invention discloses efficient energy-saving pulp dewatering and drying equipment which mainly comprises a double-roller pulp squeezing machine with a hot rolling structure, a two-segment drying chamber, a microwave generator, a heat conductive oil boiler, an air preheater, a heat exchanger and the like. The double-roller pulp squeezing machine with the hot rolling structure is characterized in that waste heat of exhaust gas of a system can be used for carrying out thermal conduction on a pulp plate so that pulp drying conditions can be optimized; the two-segment drying chamber carries out constant-speed drying and decelerating drying on pulp respectively; the microwave generator is arranged and works on a position close to a turning point from the constant-speed dewatering stage to the decelerating dewatering stage of the pulp, and is used for improving the drying speed of a pulp decelerating drying segment and reducing energy consumption; the air preheater is used for recycling the waste heat of flue gas exhausted by the thermal conductive oil boiler and preheating fresh air supplemented to the system. The efficient energy-saving pulp dewatering and drying equipment has the advantages of being simple, high in drying speed, high in energy utilization rate, wide in application range and the like.

Owner:JIMEI UNIV

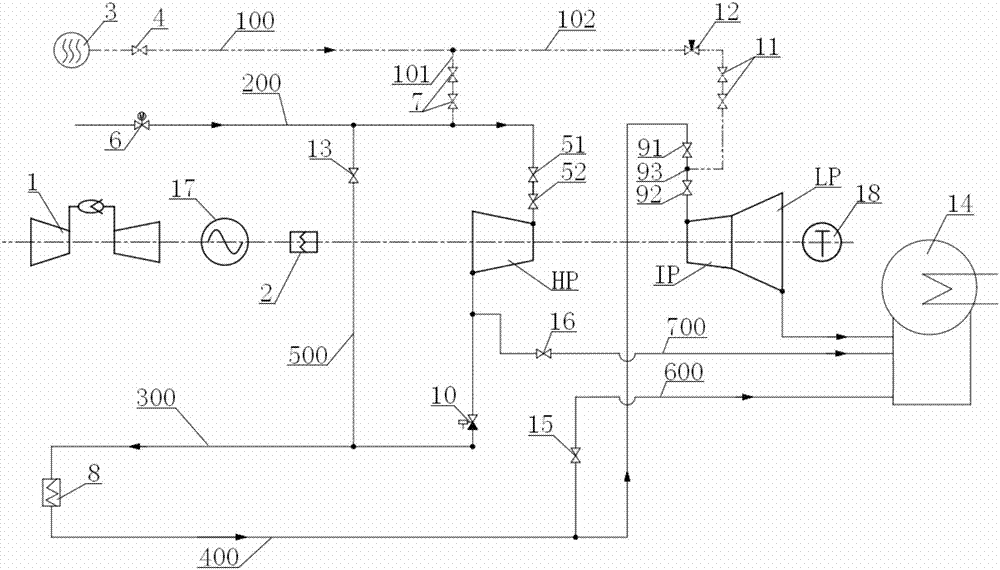

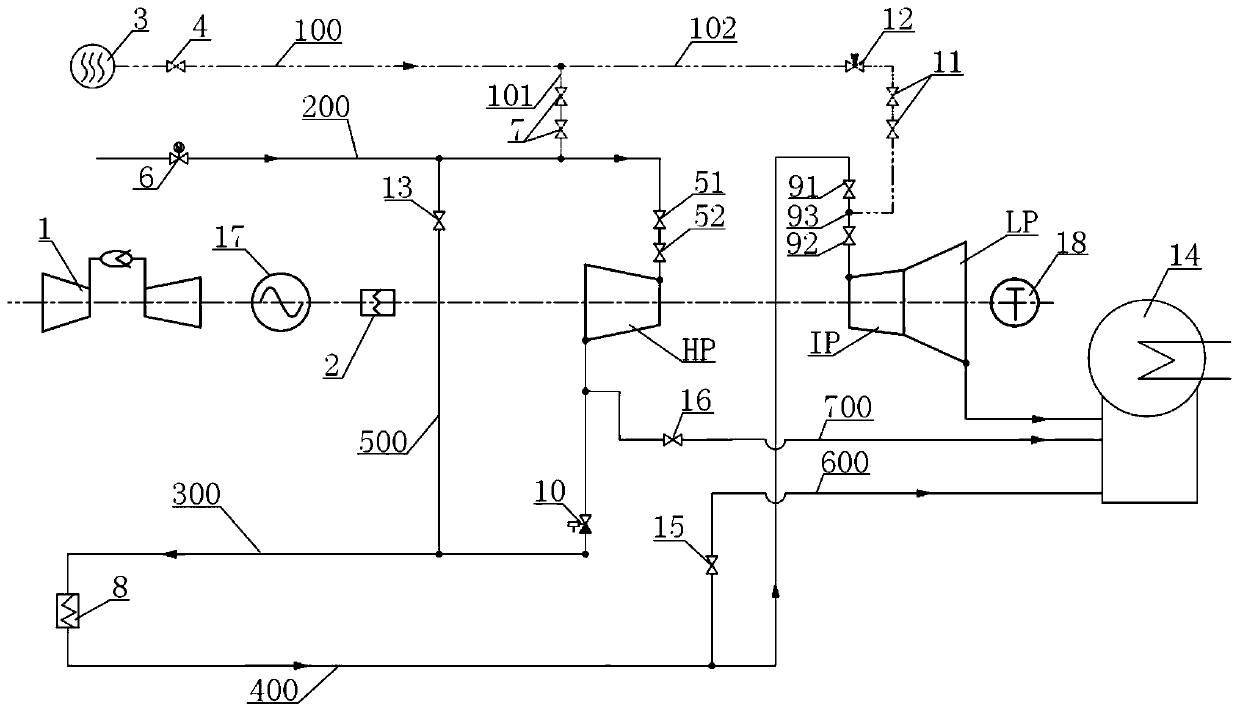

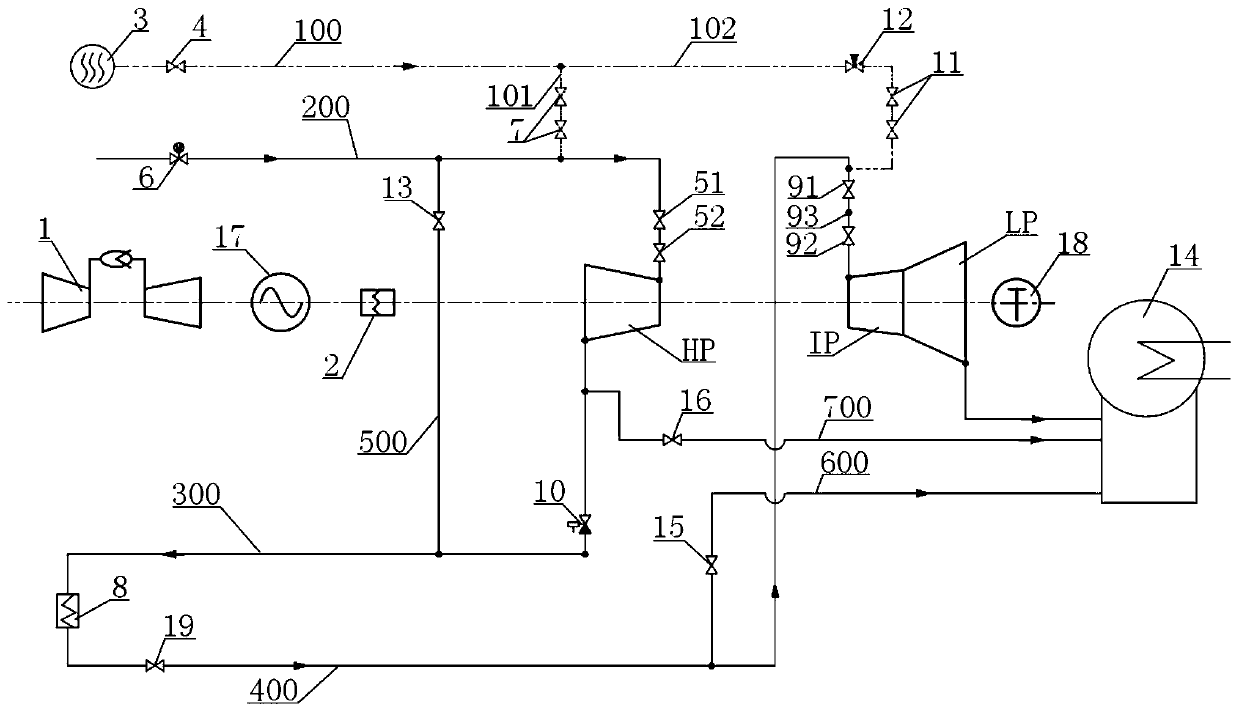

Quick combined cycle steam turbine starting and warming system and method

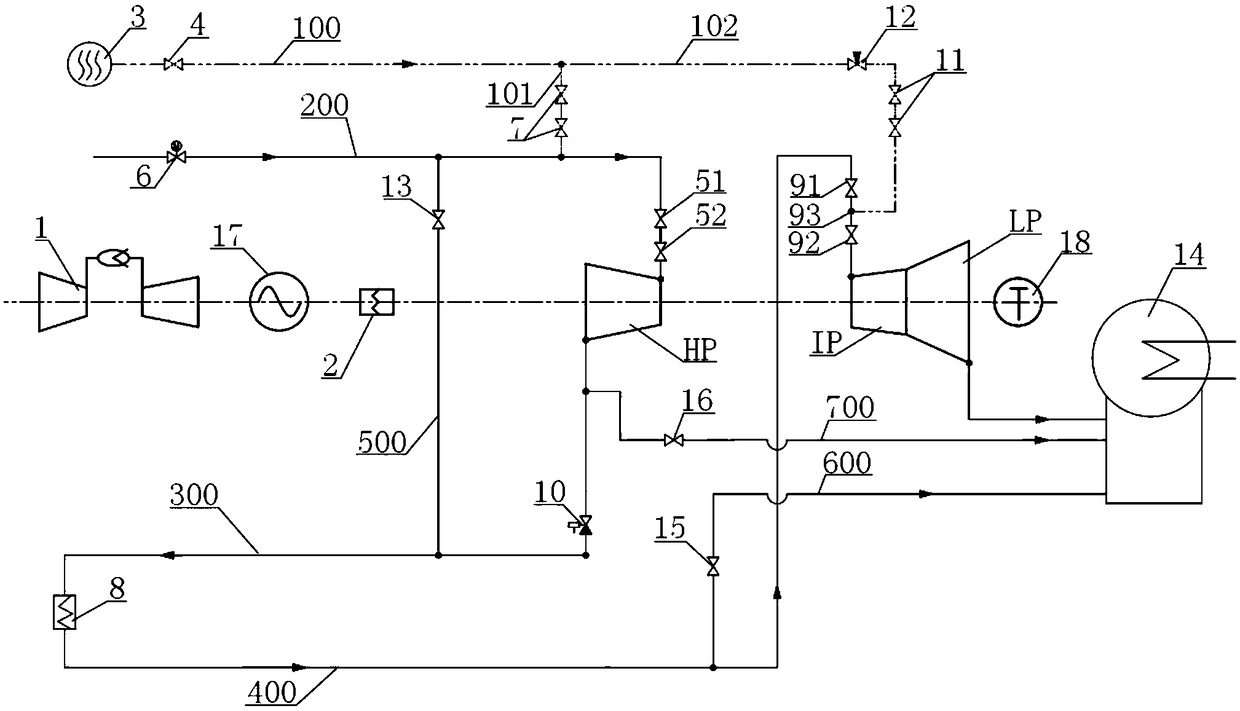

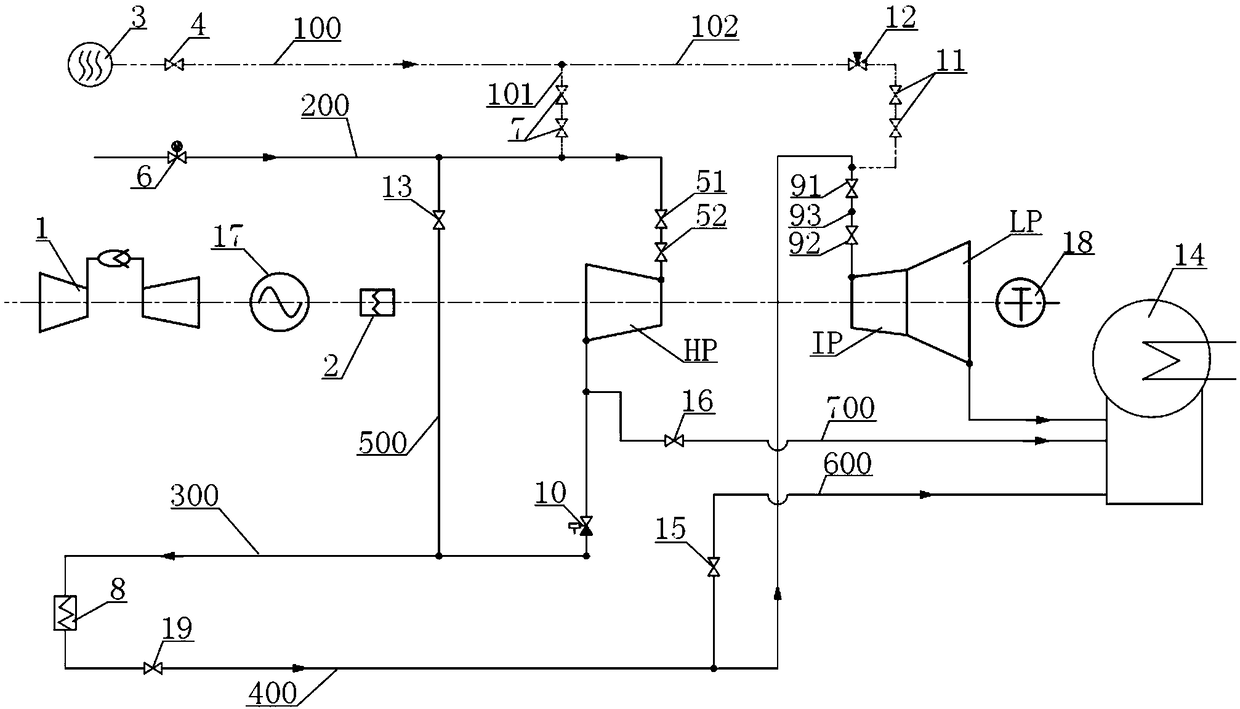

ActiveCN107227979ARaise initial temperatureIncrease flexibilityGas turbine plantsInterengaging clutchesEngineeringElectric generator

The invention relates to the technical field of fuel gas-steam combined cycle systems, in particular to a quick combined cycle steam turbine starting and warming system and method. The system comprises a gas turbine, a power generator, a self-synchronizing clutch, a steam turbine, a steam turbine turning gear and a warming steam source. The steam turbine comprises a high pressure cylinder, an intermediate pressure cylinder and a lower pressure cylinder. Warming steam conveying pipelines leading to the high pressure cylinder, the intermediate pressure cylinder and the lower pressure cylinder are connected to the warming steam source. The method comprises the steps that the rotating speed of the steam turbine is increased through the steam turbine turning gear so as to be higher than the rotating speed of the gas turbine; a main screw-type sliding part of the clutch is pried with a manual lever, so that the main screw-type sliding part slides towards the input end of the clutch till the phase positions of driving teeth and the phase positions of driven teeth of the clutch are aligned, and engagement of the clutch is achieved; warming steam is injected into the steam turbine, the steam turbine drives the gas turbine to rotate, and warming starts to be conducted; and when the temperature of an intermediate pressure rotor of the steam turbine reaches the preset temperature or the warming time reaches the preset time, warming is stopped. The cold start time can be shortened.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD +2

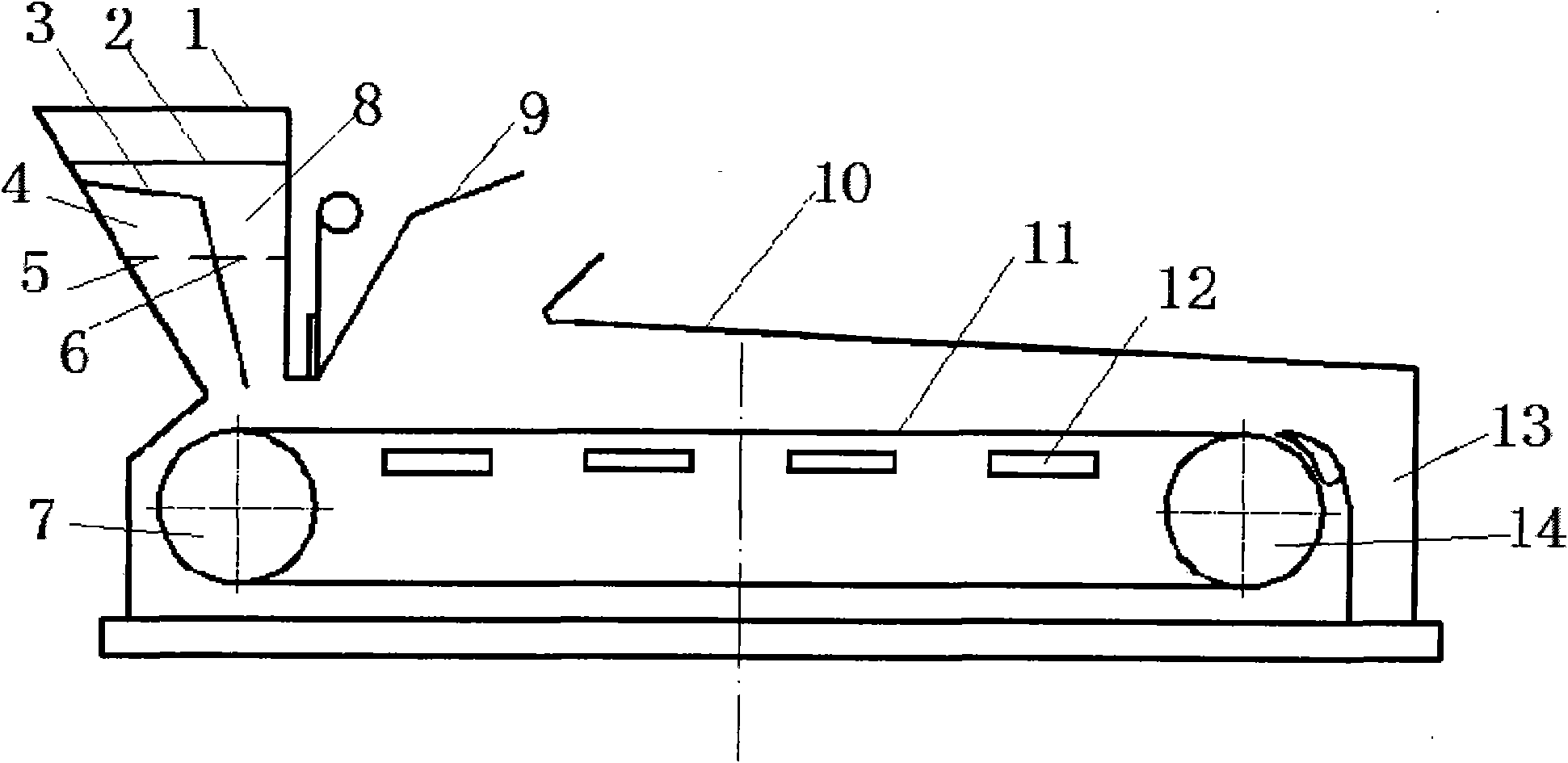

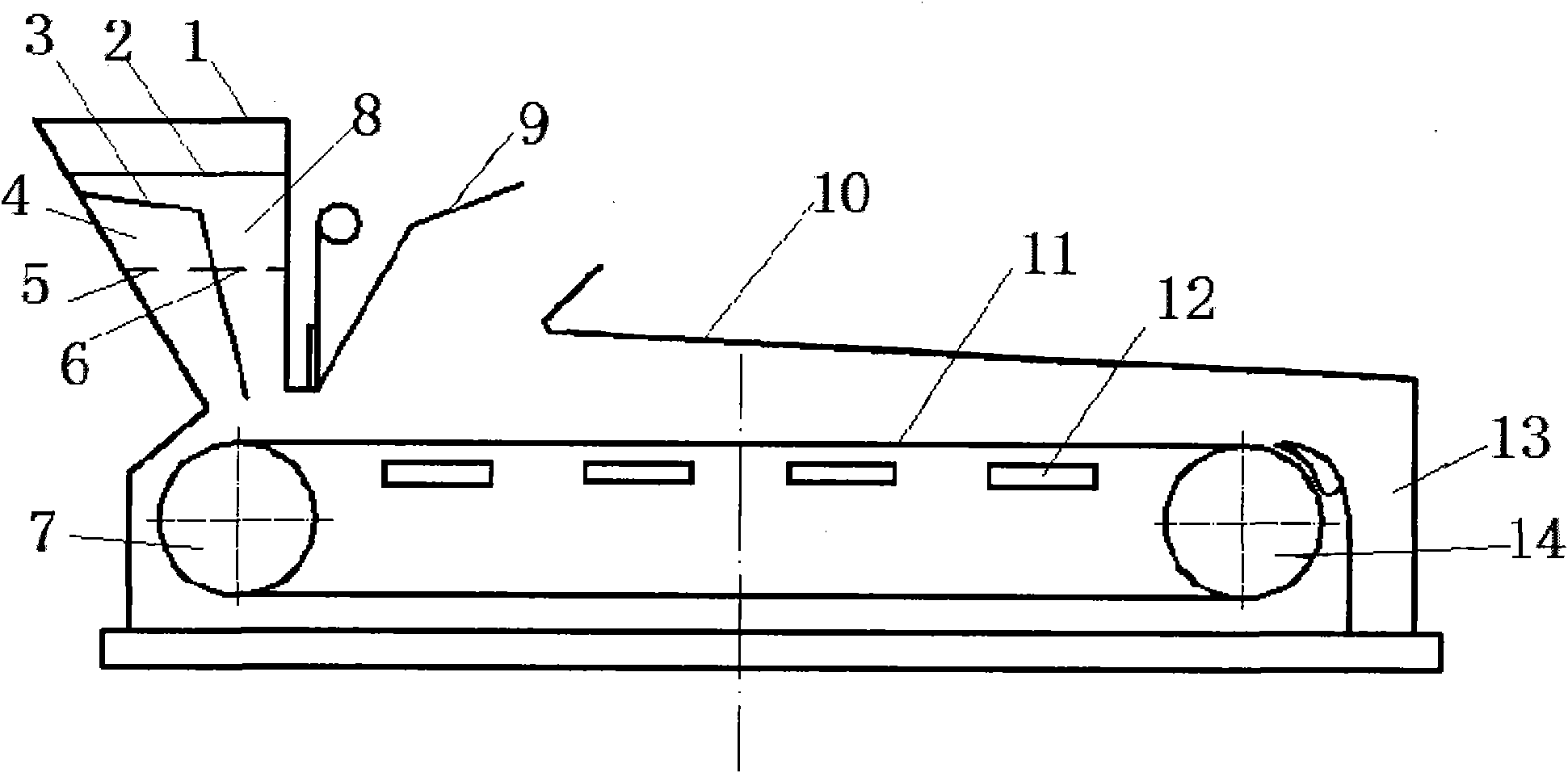

Petroleum coke direct burner

InactiveCN101852427AEasy to burnBurn quicklySolid fuel combustionIndirect carbon-dioxide mitigationAir preheaterCombustor

The invention discloses a petroleum coke direct burner, comprising a hopper, a fire grate, air chambers and a deslagging channel, wherein, the fire grate is driven by a driving shaft and a driven shaft to rotate; a front arch is arranged on an upper front wall, and a rear arch is arranged on a rear wall; the deslagging channel is arranged between the fire grate and the rear wall; a plurality of the air chambers are arranged under the fire grate; the hopper is arranged outside the front wall and is internally provided with a sizing screen; the lower space of a separating baffle plate is divided into a coarse material box and a fine material box, the coarse material box is provided with a coarse material gate for controlling discharge speed, and the fine material box is provided with a fine material gate for controlling discharge speed; and the air supply system of the air chamber is provided with an air preheater. The petroleum coke direct burner can be widely applied in the field of boiler combustion equipment, and has the advantages of simple structure, easy ignition and high combustion efficiency.

Owner:SOUTH CHINA UNIV OF TECH

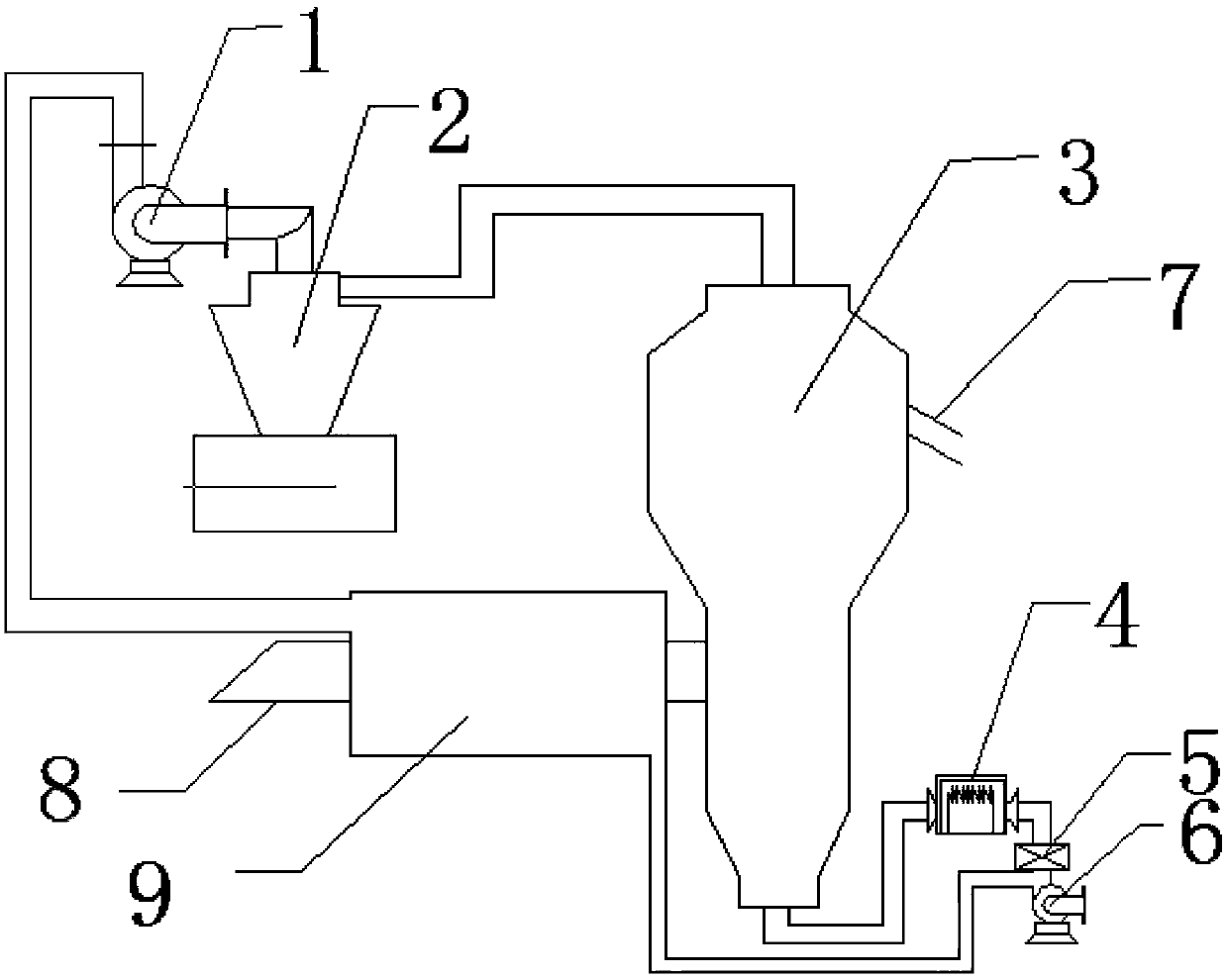

Combined heat and carbon dioxide supply system for greenhouse

InactiveCN109258241ATo achieve the purpose of comprehensive utilizationImprove efficiencyClimate change adaptationGreenhouse cultivationWater bathsLiquid water

The invention provides a combined heat and carbon dioxide supply system for a greenhouse. The system comprises a biomass boiler, a heat exchanger and a gas purifying room, wherein a steam outlet, a liquid water inlet, a smoke outlet and an air inlet are formed in the biomass boiler, the greenhouse is internally provided with a heat supply pipe and a carbon dioxide spraying pipe, the heat supply pipe is in closed-loop connection with the steam outlet and the liquid water inlet, the smoke outlet is connected with the heat exchanger, the gas purifying room and the carbon dioxide spraying pipe insequence, and the air inlet is connected with an outlet of the heat exchanger. The gas purifying room comprises a water-bath dust remover, a sedimentation tank and a water supply pump; an air inlet and an air outlet are formed in the water-bath dust remover, and the water-bath dust remover is communicated with the bottom of the sedimentation tank; a water outlet of the sedimentation tank is in closed-loop connection with the water supply pump and a water inlet of the water-bath dust remover in sequence; the air outlet is connected with the carbon dioxide spraying pipe. The greenhouse is heatedby steam generated by the biomass boiler, and smoke is purified and then provides carbon dioxide for the greenhouse.

Owner:JIANGSU UNIV

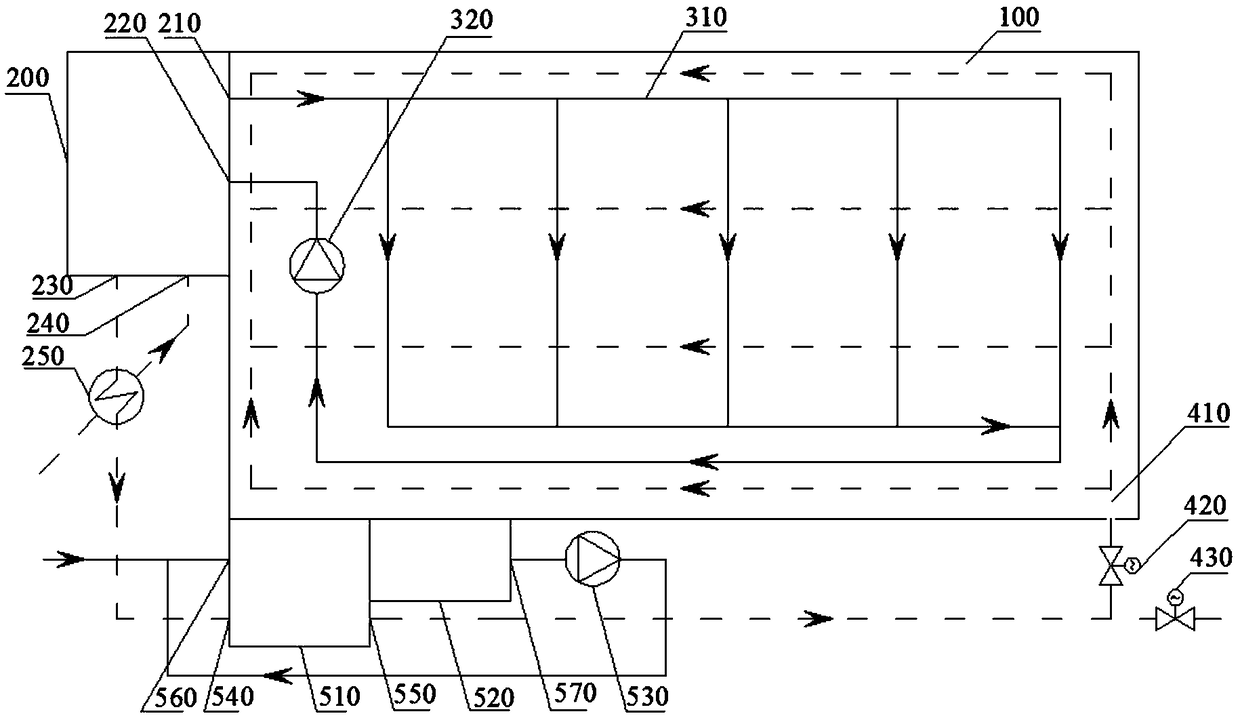

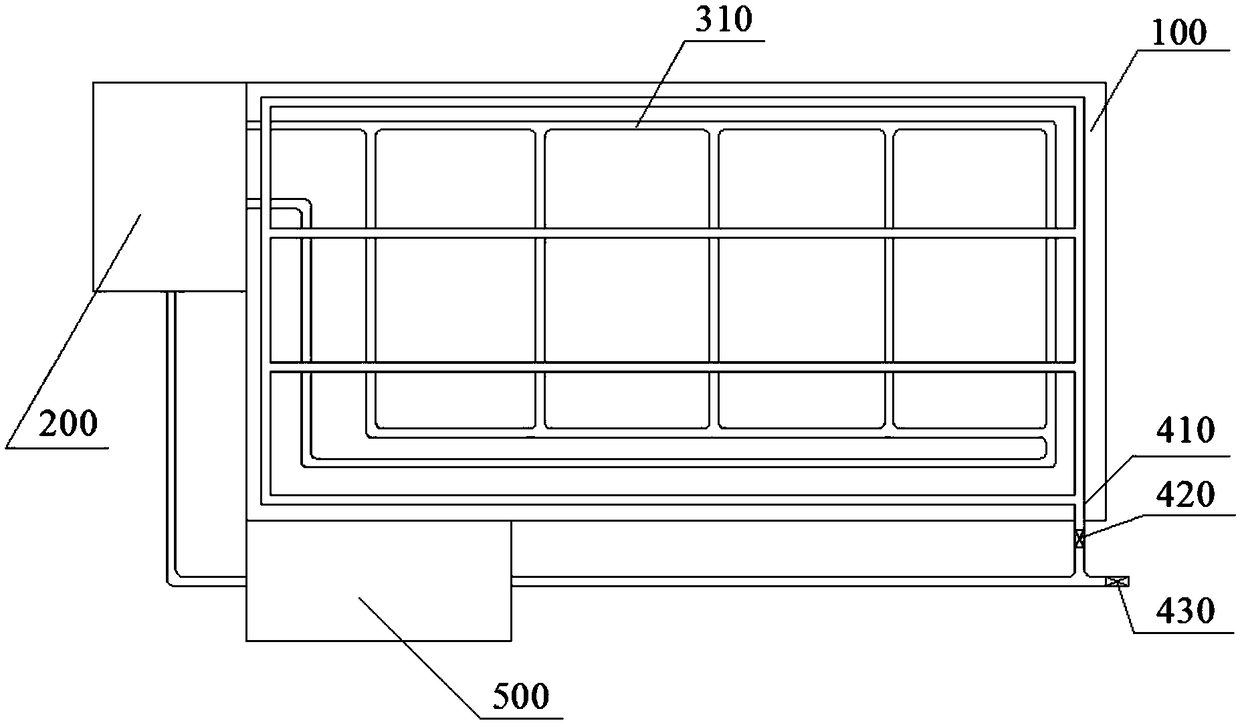

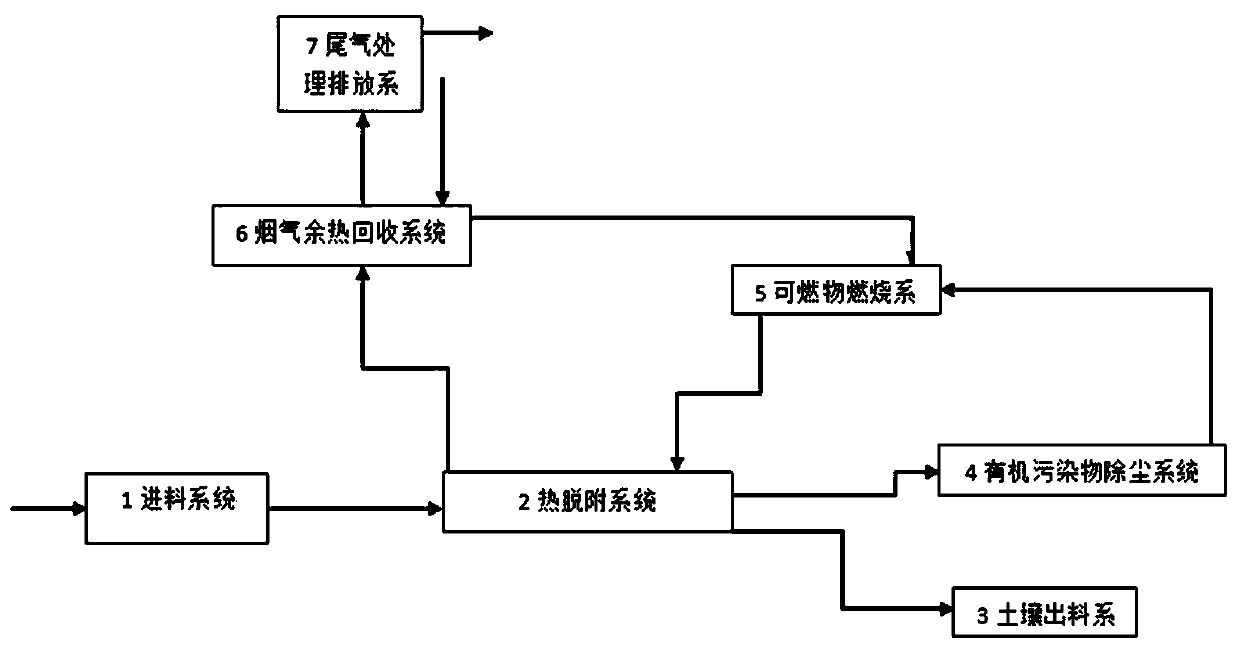

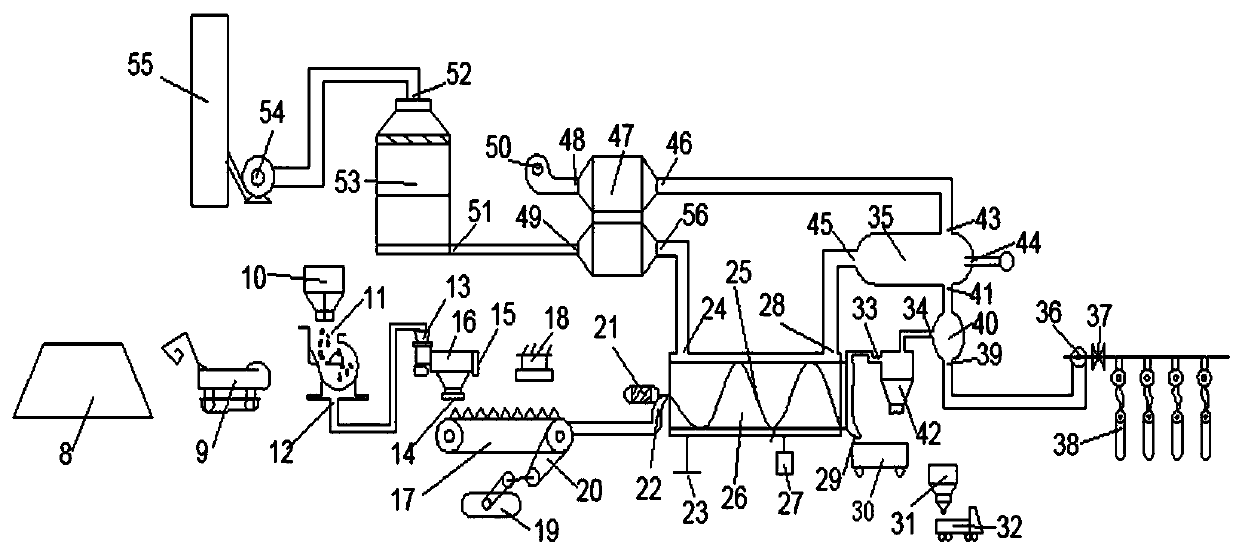

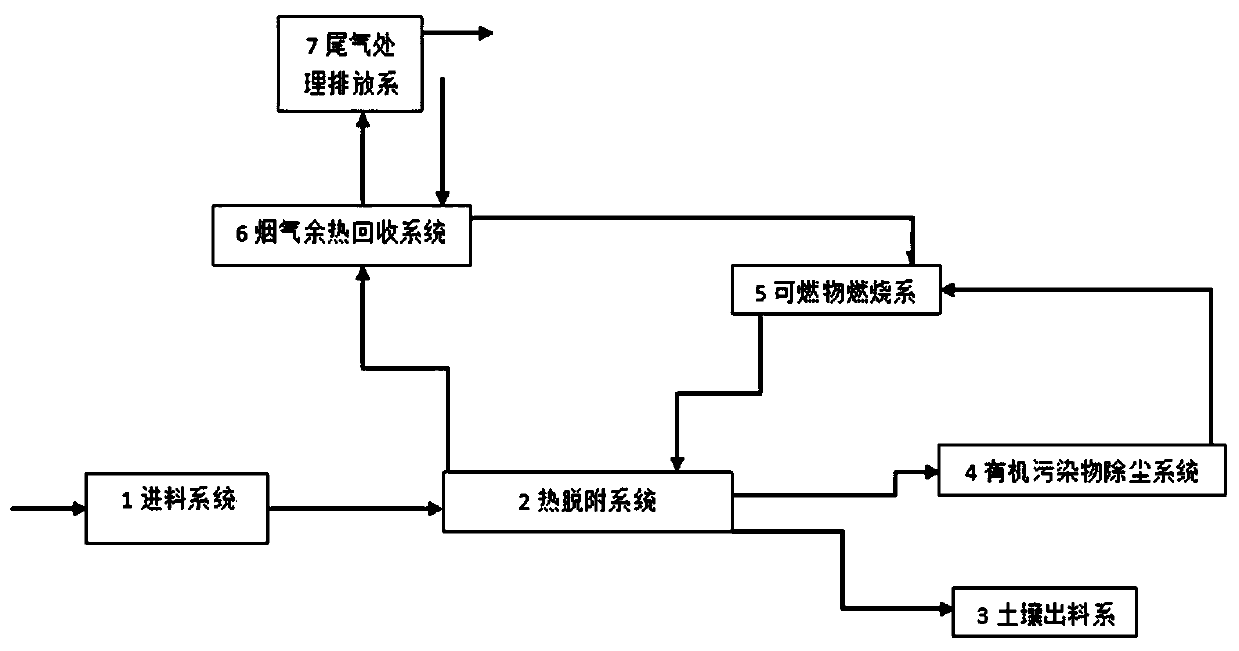

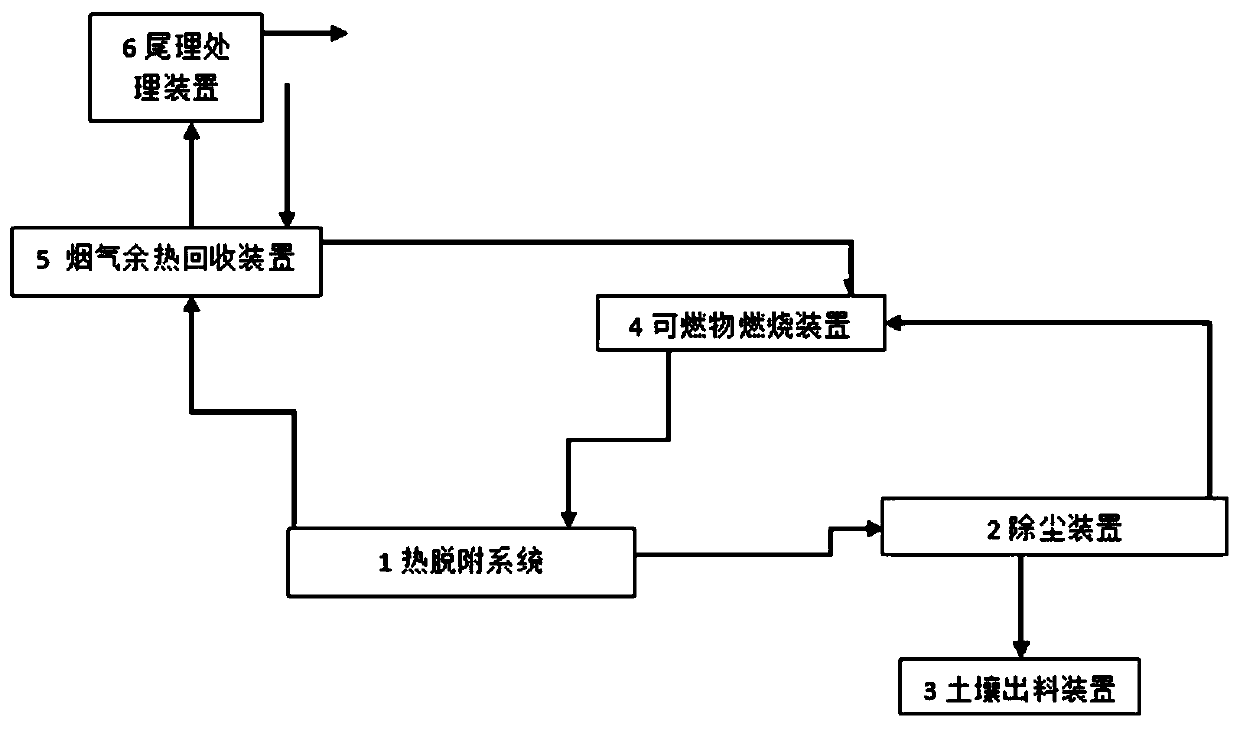

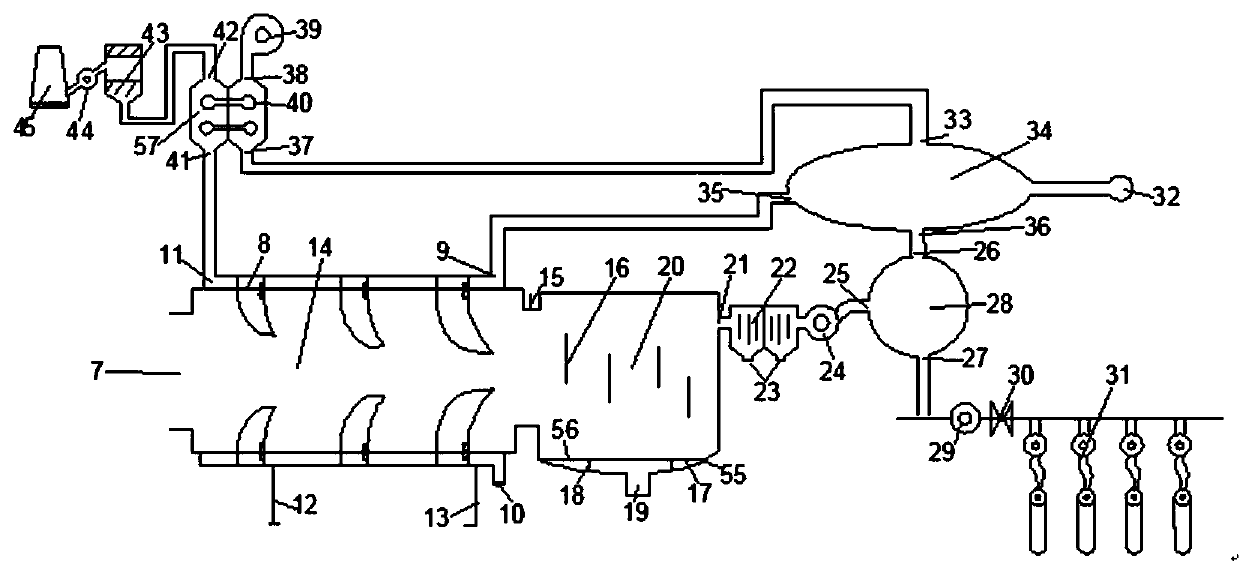

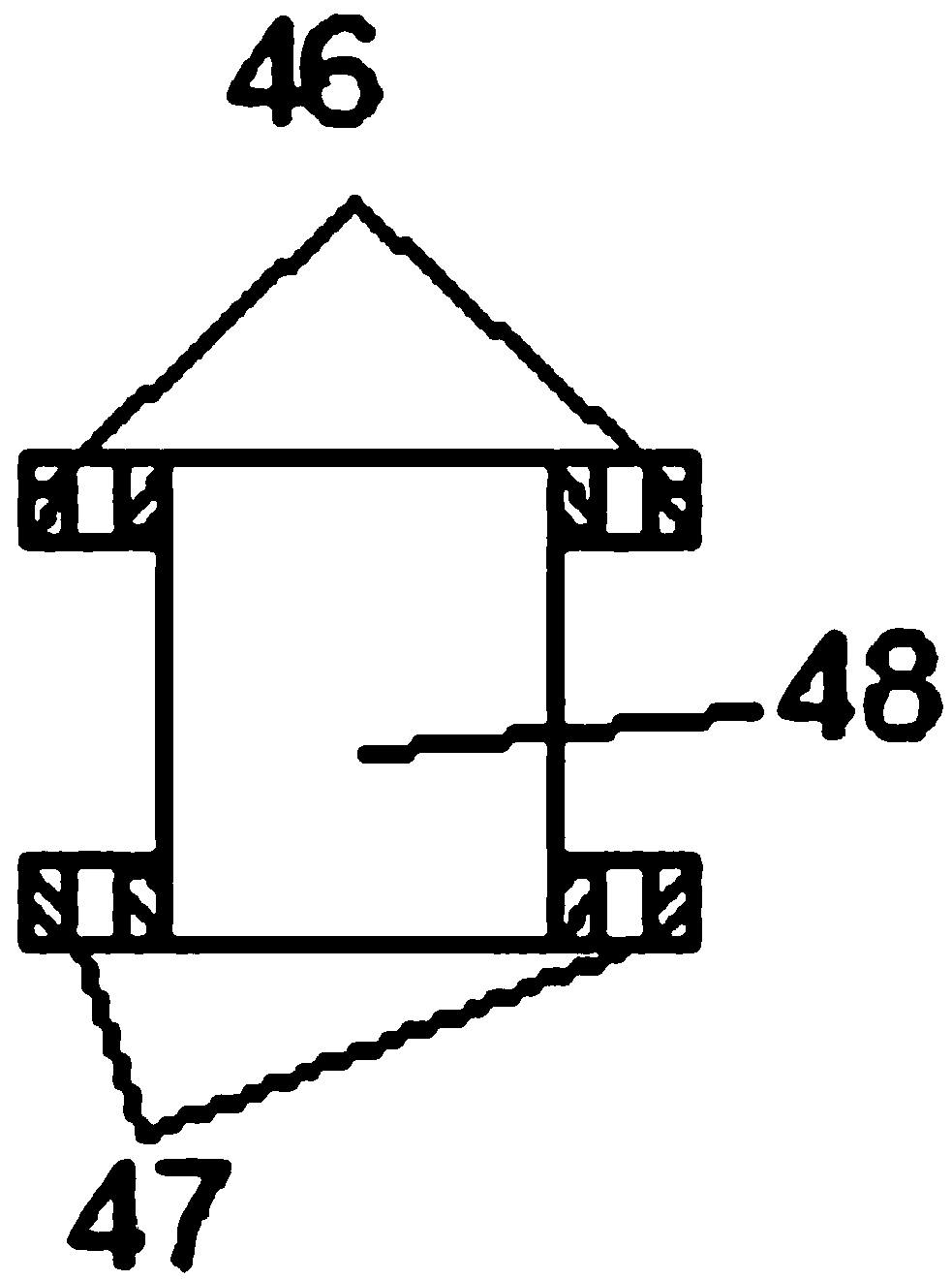

Thermal remediation system for organic matter contaminated soil through double-phase transformation heat treatment

InactiveCN111014268AAvoid generatingReduce the burden onContaminated soil reclamationIncinerator apparatusCrusherThermal desorption

The invention relates to a thermal remediation system for organic matter contaminated soil through double-phase transformation heat treatment. The system comprises a feeding system, a thermal desorption system, an organic pollutant dust removal system, a combustible combustion system, a flue gas waste heat recovery system and a tail gas treatment emission system, wherein the feeding system consists of a hammer crusher communicated with an organic contaminated soil inlet, a screening machine communicated with an outlet of the hammer crusher, a conveying belt communicated with an outlet of the screening machine, and an iron remover above an outlet of the conveying belt; a soil feeding port of the thermal desorption system is connected with an outlet of a belt conveyor, a lower end outlet ofthe tail of the thermal desorption system is communicated with a steel type conveying belt, and an upper end outlet of the tail of the thermal desorption system is communicated with the organic pollutant dust removal system. Energy consumption and tail gas treatment costs are reduced, organic pollutant heat and flue gas waste heat can be recycled, fuel is saved, energy consumption is reduced, thetreatment efficiency is high, tail gas is discharged after being treated, and environmental protection is facilitated.

Owner:TIANJIN UNIV

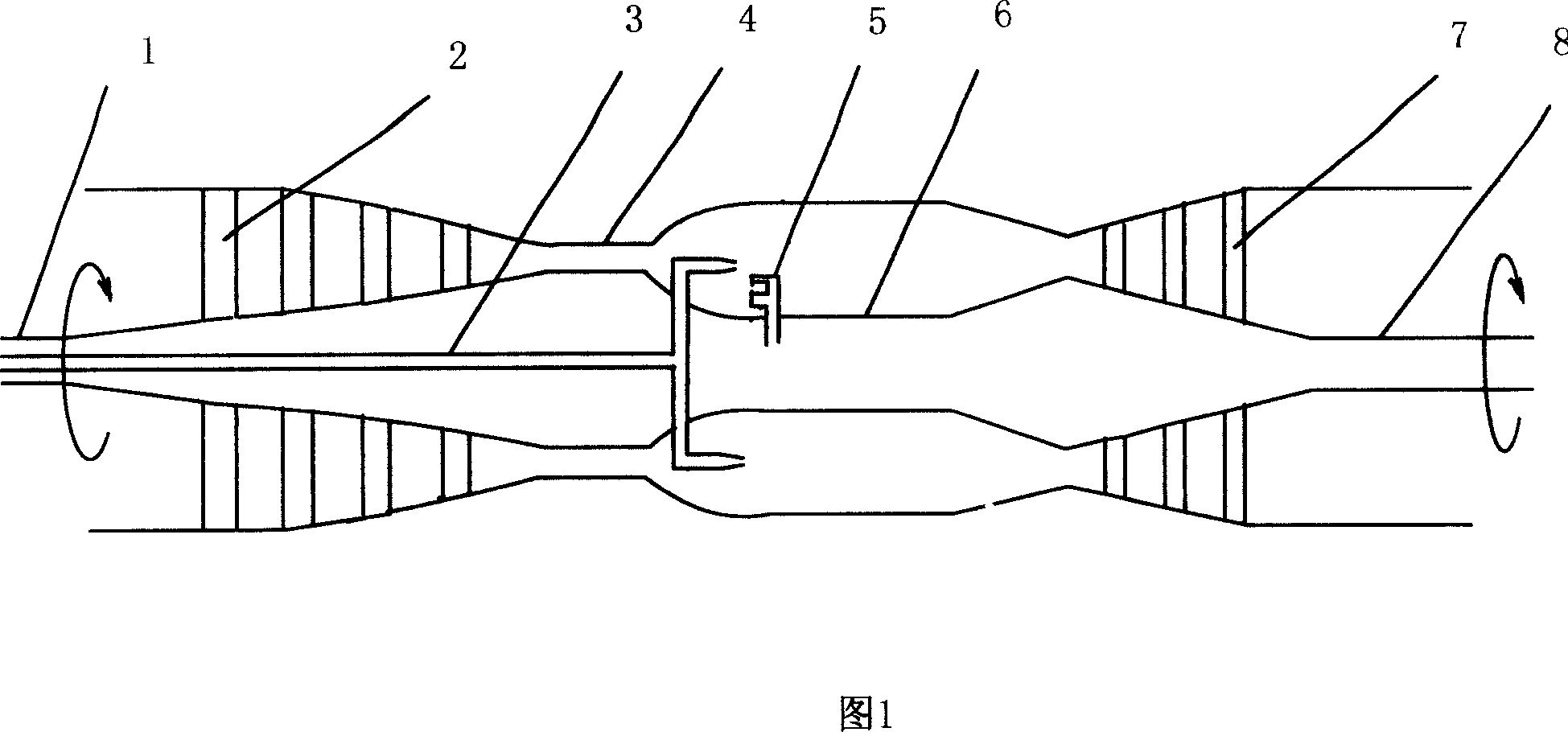

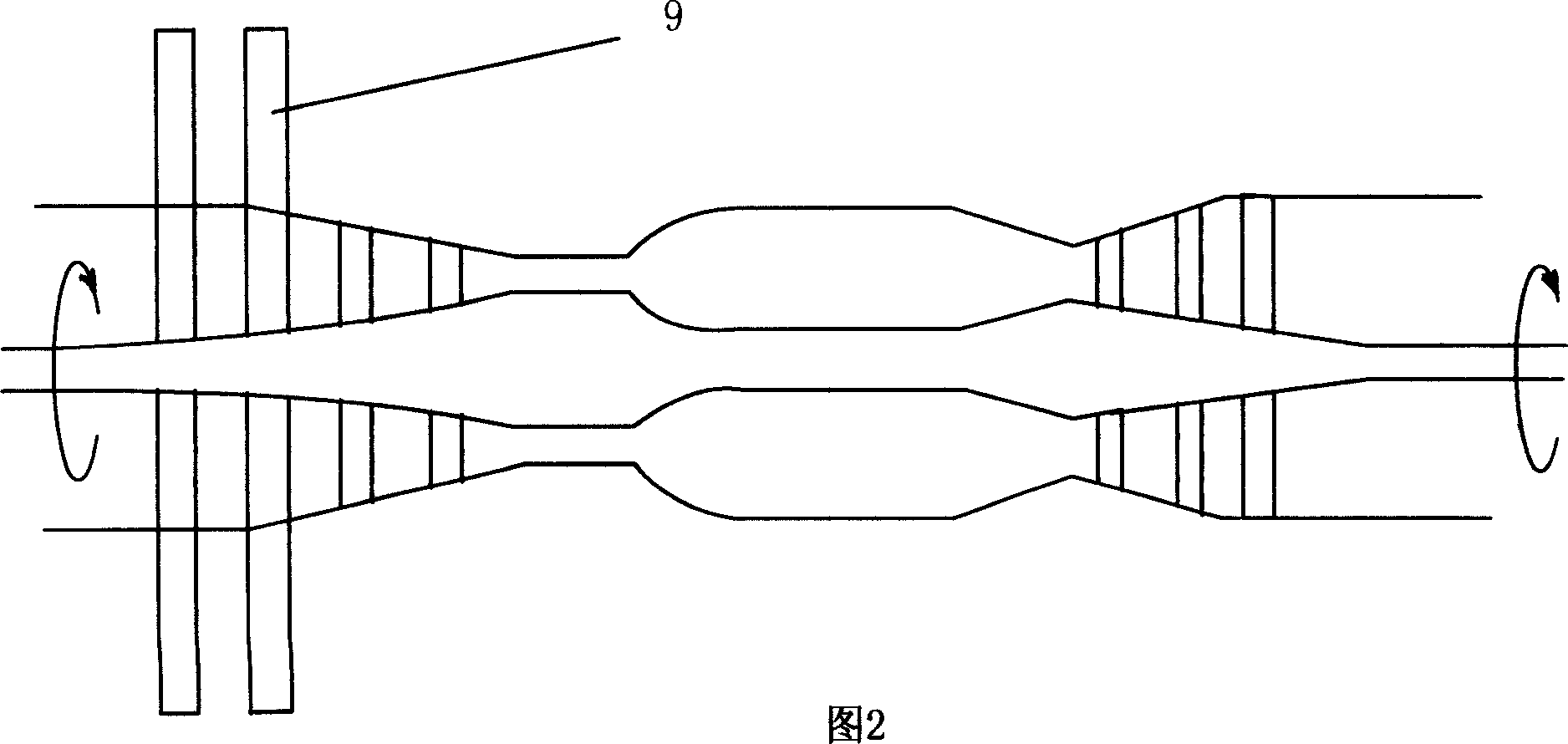

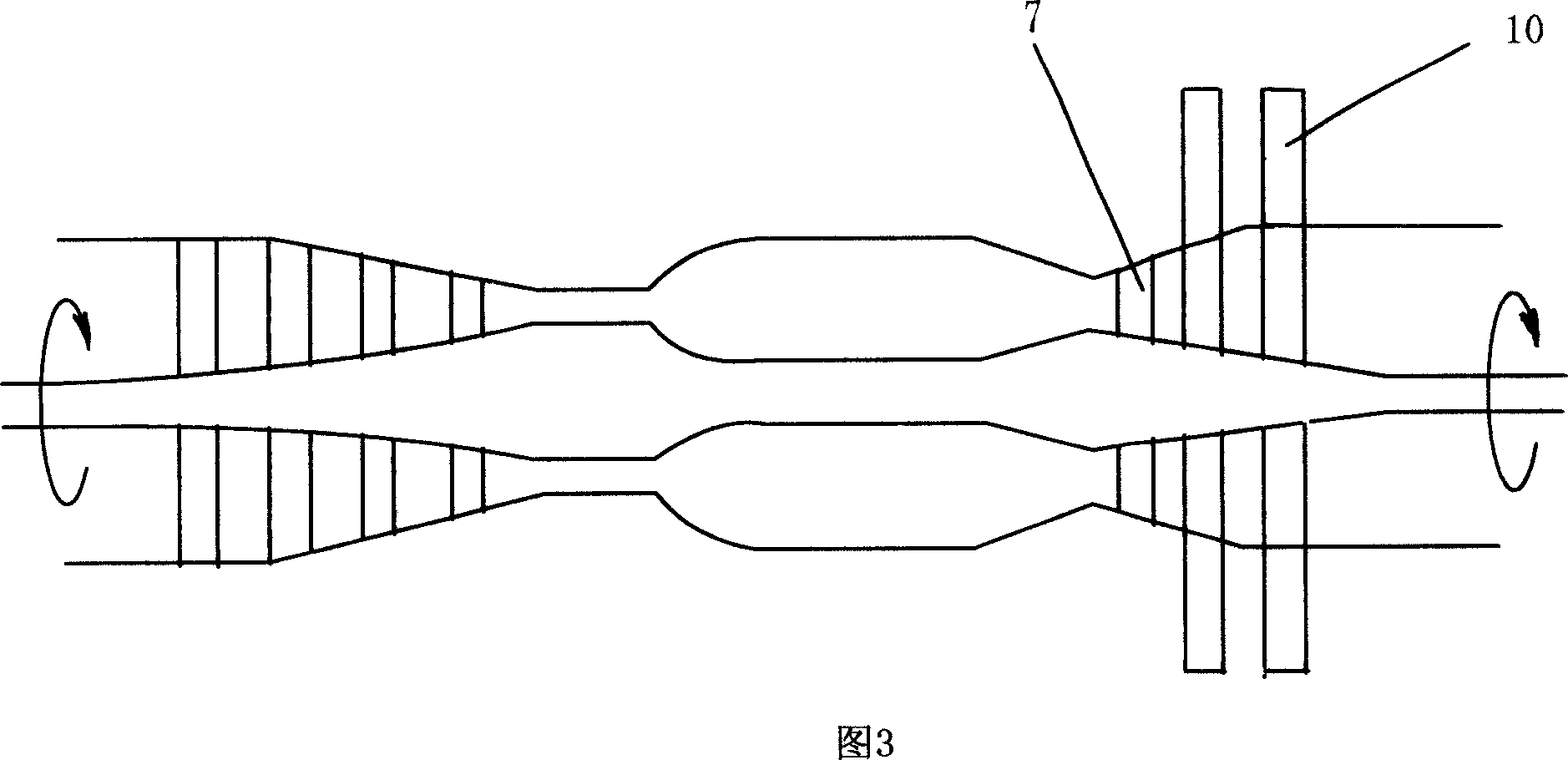

Rotary jet engine

InactiveCN1924319AEasy to dissipate heatRaise the initial gas temperatureGas turbine plantsNozzleRotary engine

Owner:李志文

Novel wind energy heating system

PendingCN108374762AExpand the form of useAvoid consumptionWind motor combinationsRenewable energy generationThermal energyEngineering

The invention provides a novel wind energy heating system which comprises a wind energy collecting device, an air power heating furnace and a speed increase unit. The wind energy collecting device comprises a first rotating shaft and rotary blades fixed to the first rotating shaft in the circumferential direction, and the rotary blades rotate under the effect of wind energy to drive the first rotating shaft to rotate; the air power heating furnace comprises a furnace wall, a second rotating shaft arranged in the furnace wall, a plurality of restriction orifices and a plurality axial flow blades fixed to the second rotating shaft; center holes of the multiple axial flow blades are arranged on the second rotating shaft in a sleeving manner and are arranged in the axial direction of the second rotating shaft, the restriction orifices are arranged between every two corresponding adjacent axial flow blades, and the speed increase unit is connected between the first rotating shaft and the second rotating shaft. By means of the novel wind energy heating system, other unnecessary waste generated by conversion from wind energy to electric energy to heat energy is saved, and the energy resource using rate is improved; and the inlet air temperature of the air energy using equipment can be improved, the energy conversion efficiency of the air energy using equipment is improved, and the application scope of the system is expanded.

Owner:XUHAI COLLEGE CHINA UNIV OF MINING & TECH +1

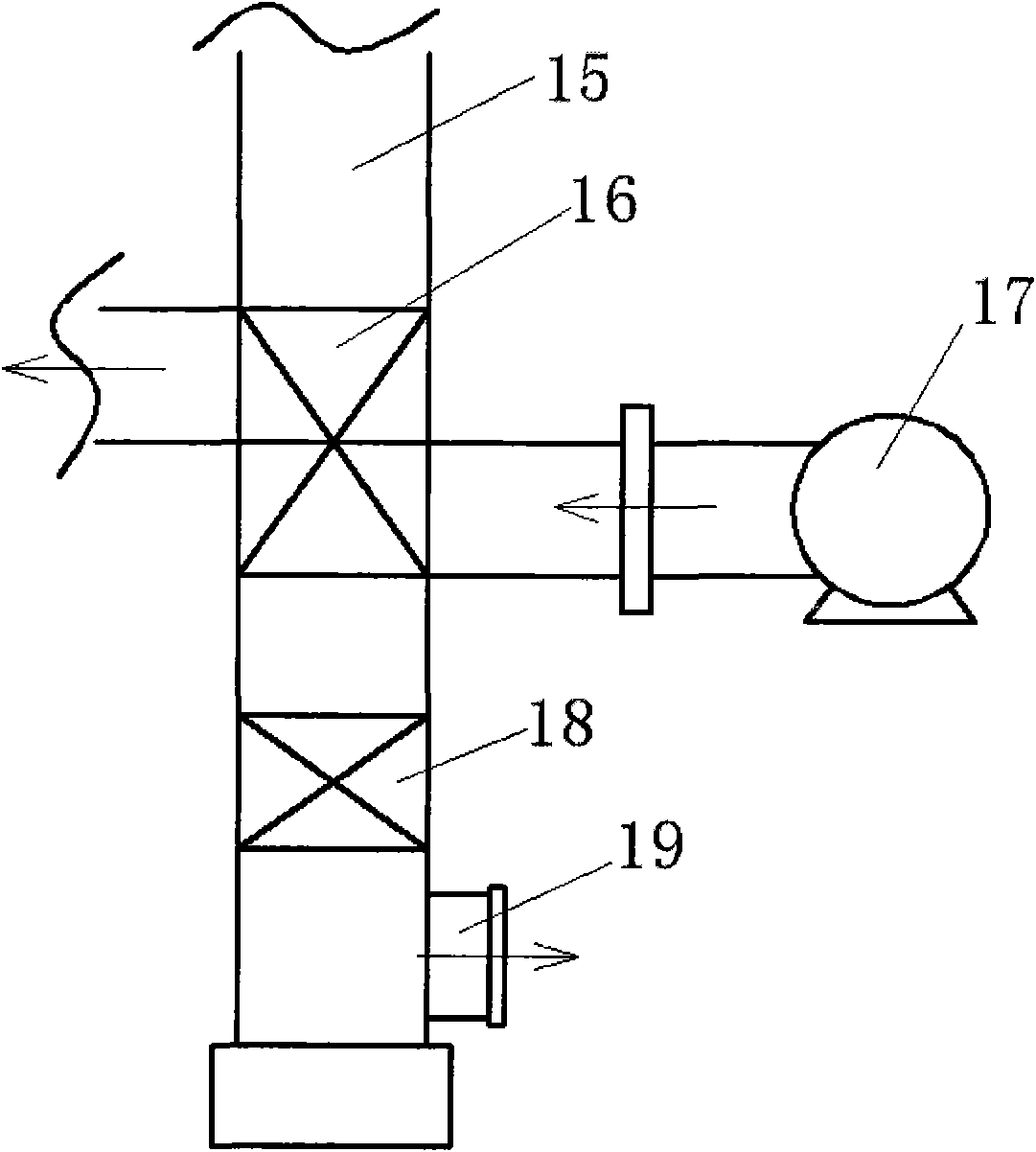

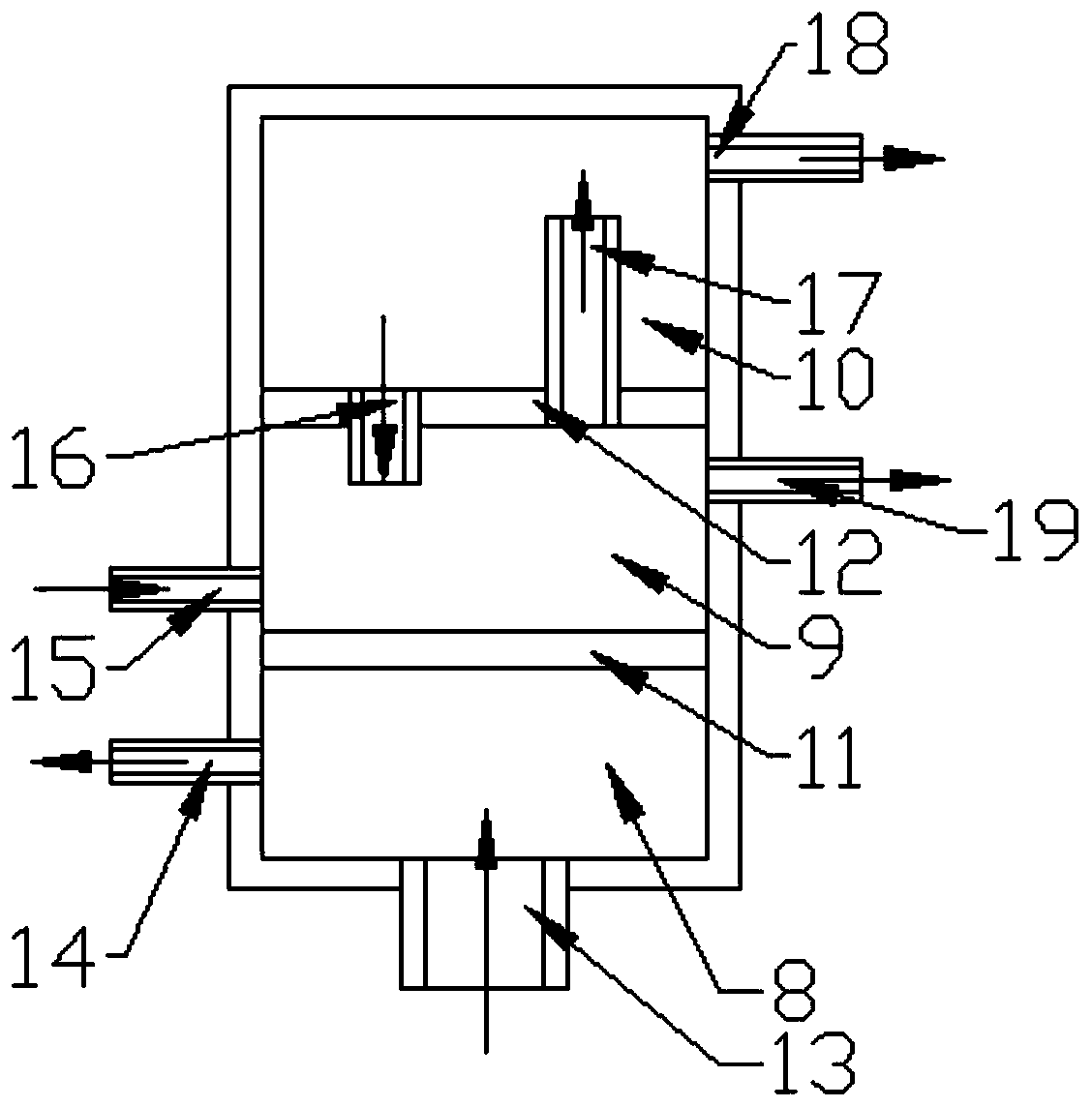

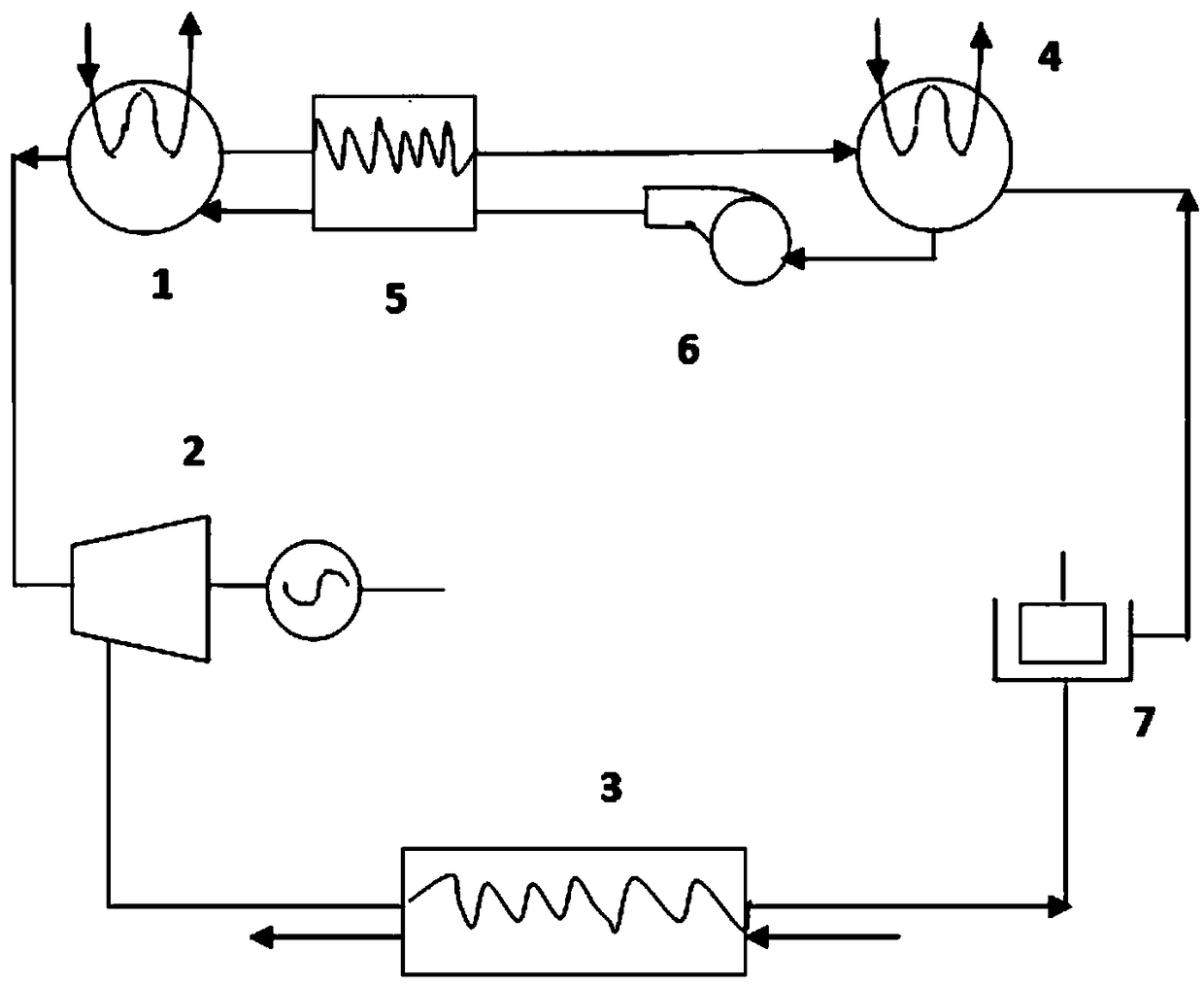

High temperature air cooled reactor direct hydrogen production coupling steam cycle power generation system and method thereof

InactiveCN105551554ARealize the function of electricity co-productionImprove heat utilizationNuclear energy generationHydrogen productionCogenerationSuperheater

The invention discloses a high temperature gas cooled reactor direct hydrogen production coupling steam cycle power generation system and a method thereof. The system comprises a high temperature gas cooled reactor, a conversion reactor, a steam generator, a coolant cycle pump, a steam superheater, a turbo generator set, a condenser, a water-feeding pump, a middle temperature converter, a steam extraction pipeline and a natural gas pipeline, wherein a helium outlet of the high temperature gas cooled reactor is connected with a helium inlet of the conversion reactor, a helium outlet of the conversion reactor is connected with the steam generator, a conversion gas outlet of the conversion reactor is connected with the steam superheater, a water steam outlet of the steam generator is connected with a steam inlet of the steam superheater, a steam outlet of the steam superheater is connected with a steam inlet of the turbo generator set, and a steam extraction port of the turbo generator set outputs a blast of steam and is connected with a raw material inlet of the conversion reactor. Through the system, a hydrogen-power cogeneration mode is realized, temperature matching, the high heat utilization rate, low hydrogen production cost and high steam cycle efficiency are realized, and the system further has excellent economic benefits and application prospects.

Owner:JIMEI UNIV

Phase-change heat transfer soil thermal remediation system

InactiveCN111069262AIncrease processing rateImprove heat transfer efficiencyVortex flow apparatusRotary drum furnacesDust controlThermal desorption

The invention discloses a phase-change heat transfer soil thermal remediation system. The system comprises a thermal desorption system, a dust removal device, a combustible combustion device, a soil discharge device, a waste heat recovery device and a waste gas treatment device, the thermal desorption system is communicated with the dust removal device; the dust removal device is communicated withthe soil discharge device and the combustible combustion device; the combustible combustion device is communicated with the thermal desorption system; the thermal desorption system is connected to the waste heat recovery device, and the waste heat recovery device is connected to the exhaust gas treatment device and the combustible combustion device, the system is used for solving the problems that combustion is complex, separated organic pollutants are not utilized, resources are wasted, substances are difficult to combust, flue gas heat is not further utilized, and the heat efficiency of thesystem is reduced.

Owner:TIANJIN UNIV

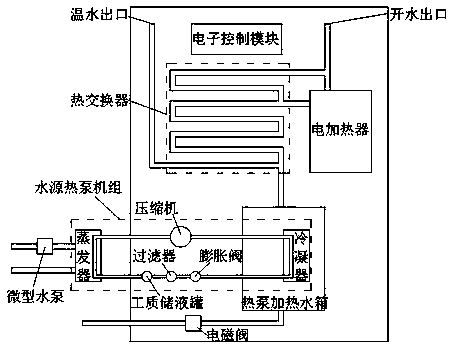

Novel energy-saving water boiling equipment

The invention discloses novel energy-saving water boiling equipment, and relates to the field of new energy resources energy-saving equipment. According to the novel energy-saving water boiling equipment, a water source heat pump and a pipe-in-pipe heat exchanger and the like are adopted, so that under the same condition, the time of cold water being heated to boiling is greatly shortened; a goodheat preservation measure and an ingenious structure are adopted, so that the heat loss is reduced as much as possible; and according to the independently-designed pipe-in-pipe heat exchanger, high-temperature water passes through the inner pipe and low-temperature water passes through the outer pipe, and compared with the prior art, lost heat can be reduced, and meanwhile, the low-temperature water can be preheated and the high-temperature water can be cooled, so that the expected effect of simultaneously supplying boiled water and warm water can be achieved. The equipment has strong practicability in actual production and life; and the water source heat pump can operate under the variable working conditions and can still keep operating steadily under the condition of repeated starting and stopping, so that the water boiling equipment has extremely high reliability.

Owner:徐州赛诺过滤科技有限公司

High-temperature gas-cooled reactor direct hydrogen production coupled steam cycle power generation system and method

InactiveCN105551554BRealize the function of electricity co-productionImprove heat utilizationNuclear energy generationHydrogen productionCogenerationSuperheater

The invention discloses a high temperature gas cooled reactor direct hydrogen production coupling steam cycle power generation system and a method thereof. The system comprises a high temperature gas cooled reactor, a conversion reactor, a steam generator, a coolant cycle pump, a steam superheater, a turbo generator set, a condenser, a water-feeding pump, a middle temperature converter, a steam extraction pipeline and a natural gas pipeline, wherein a helium outlet of the high temperature gas cooled reactor is connected with a helium inlet of the conversion reactor, a helium outlet of the conversion reactor is connected with the steam generator, a conversion gas outlet of the conversion reactor is connected with the steam superheater, a water steam outlet of the steam generator is connected with a steam inlet of the steam superheater, a steam outlet of the steam superheater is connected with a steam inlet of the turbo generator set, and a steam extraction port of the turbo generator set outputs a blast of steam and is connected with a raw material inlet of the conversion reactor. Through the system, a hydrogen-power cogeneration mode is realized, temperature matching, the high heat utilization rate, low hydrogen production cost and high steam cycle efficiency are realized, and the system further has excellent economic benefits and application prospects.

Owner:JIMEI UNIV

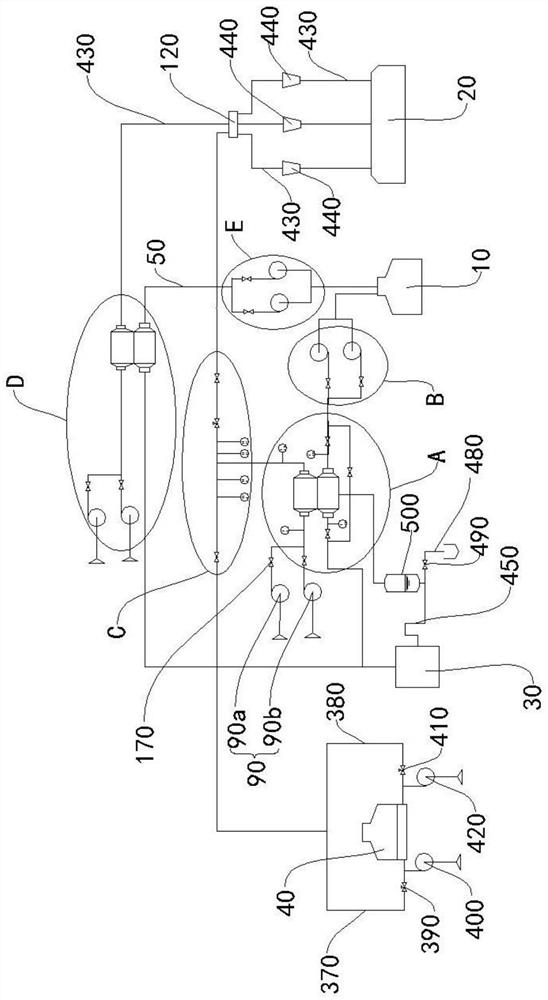

A system and method for quickly starting and warming up a combined cycle steam turbine

ActiveCN107227979BRaise initial temperatureIncrease flexibilityGas turbine plantsInterengaging clutchesEngineeringSynchronizing

The invention relates to the technical field of fuel gas-steam combined cycle systems, in particular to a quick combined cycle steam turbine starting and warming system and method. The system comprises a gas turbine, a power generator, a self-synchronizing clutch, a steam turbine, a steam turbine turning gear and a warming steam source. The steam turbine comprises a high pressure cylinder, an intermediate pressure cylinder and a lower pressure cylinder. Warming steam conveying pipelines leading to the high pressure cylinder, the intermediate pressure cylinder and the lower pressure cylinder are connected to the warming steam source. The method comprises the steps that the rotating speed of the steam turbine is increased through the steam turbine turning gear so as to be higher than the rotating speed of the gas turbine; a main screw-type sliding part of the clutch is pried with a manual lever, so that the main screw-type sliding part slides towards the input end of the clutch till the phase positions of driving teeth and the phase positions of driven teeth of the clutch are aligned, and engagement of the clutch is achieved; warming steam is injected into the steam turbine, the steam turbine drives the gas turbine to rotate, and warming starts to be conducted; and when the temperature of an intermediate pressure rotor of the steam turbine reaches the preset temperature or the warming time reaches the preset time, warming is stopped. The cold start time can be shortened.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD +2

Petroleum coke direct burner

InactiveCN101852427BEasy to burnBurn quicklySolid fuel combustionIndirect carbon-dioxide mitigationAir preheaterCombustor

The invention discloses a petroleum coke direct burner, comprising a hopper, a fire grate, air chambers and a deslagging channel, wherein, the fire grate is driven by a driving shaft and a driven shaft to rotate; a front arch is arranged on an upper front wall, and a rear arch is arranged on a rear wall; the deslagging channel is arranged between the fire grate and the rear wall; a plurality of the air chambers are arranged under the fire grate; the hopper is arranged outside the front wall and is internally provided with a sizing screen; the lower space of a separating baffle plate is divided into a coarse material box and a fine material box, the coarse material box is provided with a coarse material gate for controlling discharge speed, and the fine material box is provided with a finematerial gate for controlling discharge speed; and the air supply system of the air chamber is provided with an air preheater. The petroleum coke direct burner can be widely applied in the field of boiler combustion equipment, and has the advantages of simple structure, easy ignition and high combustion efficiency.

Owner:SOUTH CHINA UNIV OF TECH

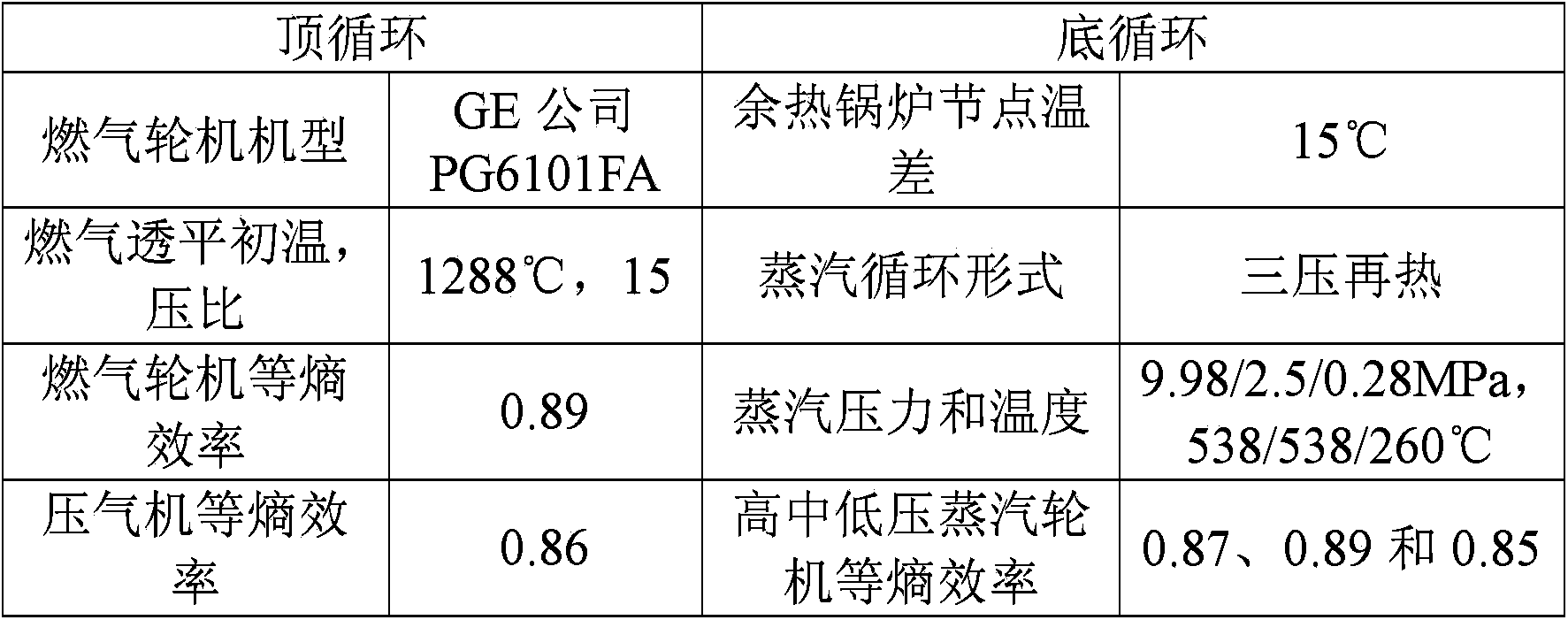

Inside and outside burning coal integrative combined cycle generation system and method

InactiveCN100504053CAchieve efficiencyPromote environmental protectionGas turbine plantsSteam generation plantsWorking fluidWater vapor

The invention relates to an internal and external coal-fired integrated combined cycle power generation system and a power generation method. The power generation system includes a coal gasification subsystem, a power cycle subsystem and a carbon dioxide recovery subsystem; The section is heated by external combustion, using the energy of semi-coke obtained from partial coal gasification; the high-temperature section is heated by internal combustion, using the energy of coal gas obtained from partial coal gasification; because the present invention adopts the internal combustion method, the initial temperature of the cycle can reach The initial temperature level of modern gas turbines; use the heat of the external combustion process to convert high-pressure water into high-pressure steam, and do not use a compressor to increase the pressure of the working medium in the cycle, thereby saving the power consumption of the working medium; the working medium of the turbine The main component is water vapor, the exhaust pressure is very low, and the cycle pressure ratio is high; carbon dioxide is automatically separated during the exothermic condensation process of the turbine exhaust; the power generation system has the advantages of high thermal efficiency, advanced environmental protection performance and good economy.

Owner:中科思道(南京)储能技术有限公司

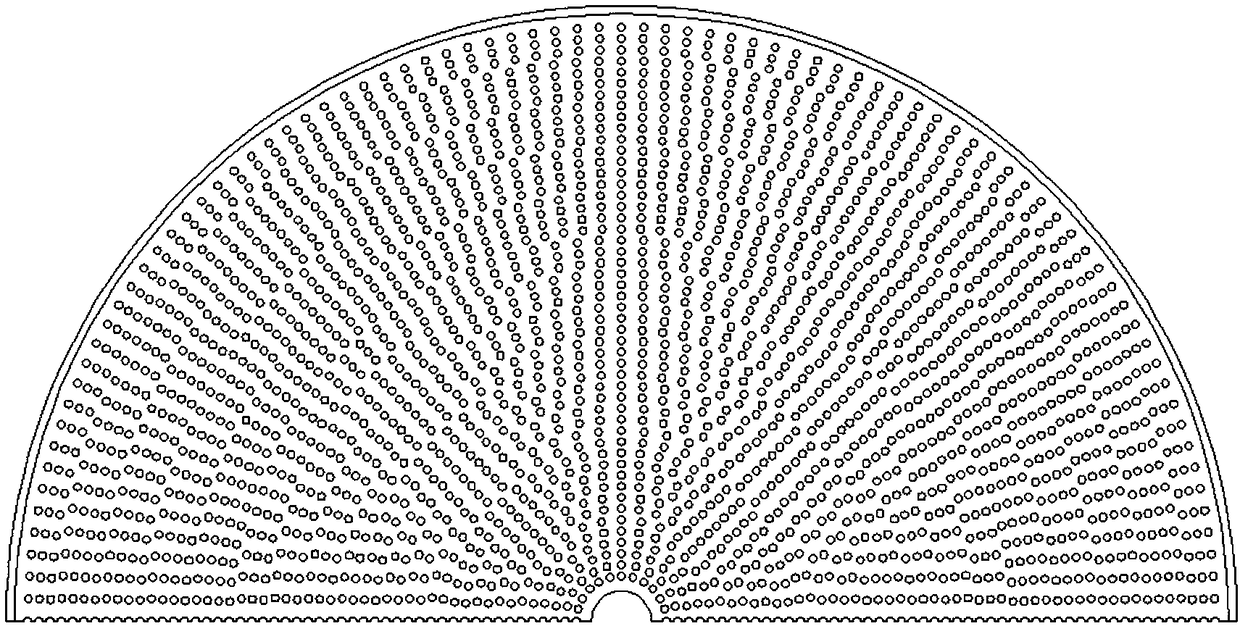

A preheating solar water heater

ActiveCN106705458BEvenly loadedReduce volumeSolar heating energySolar heat collector detailsWater sourceEngineering

Owner:JIANGSU SUNNIC SOLAR ENERGY INDAL

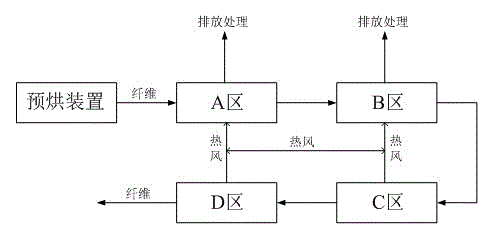

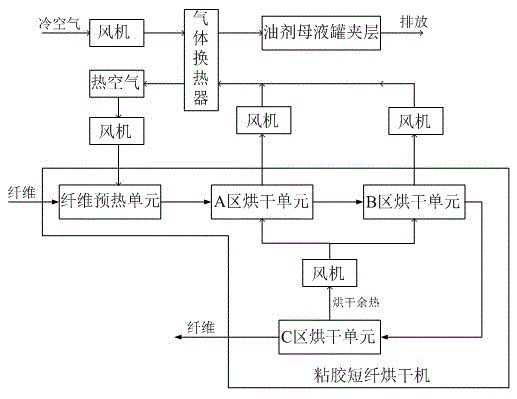

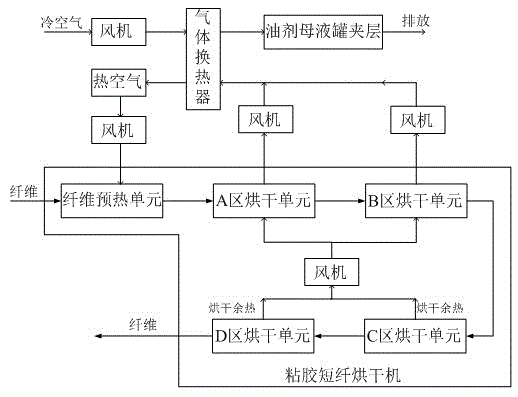

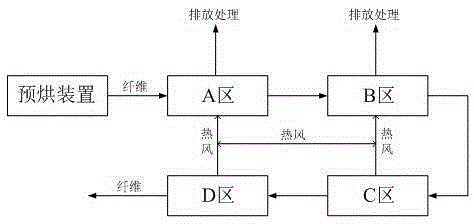

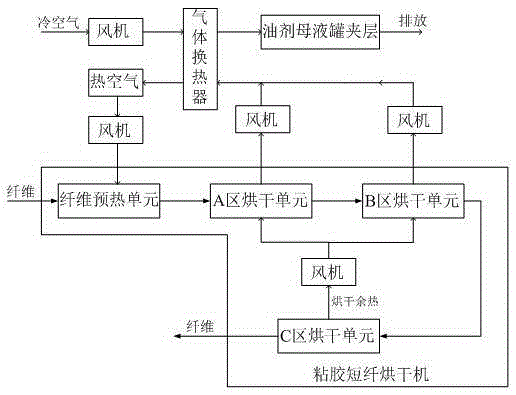

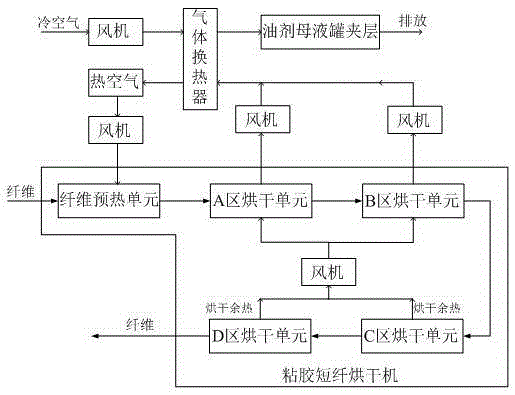

Thermal energy recycling process based on viscose staple fiber drying waste heat

ActiveCN104372551AReduce moisture contentSpeed up evaporationLiquid/gas/vapor removalTextile treatment machine arrangementsThermal energyFiber

The invention discloses a thermal energy recycling process based on viscose staple fiber drying waste heat. According to the process, waste heat of a viscose staple fiber dryer is treated in a classified mode and recycled. The viscose staple fiber dryer comprises a fiber preheating unit, a high-temperature waste heat unit and a waste heat drying unit, wherein the fiber preheating unit, the high-temperature waste heat unit and the waste heat drying unit are connected in sequence. The treatment process comprises classified treatment and recycling treatment. The design is quite reasonable; the defects that by the adoption of an existing waste gas drying and thermal energy utilization technology, classifications are unclear, the layout is not diversified, and the utilization rate is low are overcome; since waste gases in all regions of the dryer are classified according to the characteristics of the waste gases and recycled, the practicability of the waste gas drying and thermal energy utilization technology is improved, the problems of large thermal energy loss, high steam consumption, high production cost and the like in the prior art are also solved, energy conservation and consumption reduction work of an enterprise is promoted, and high social value and economic benefits are obtained.

Owner:YIBIN GRACE +2

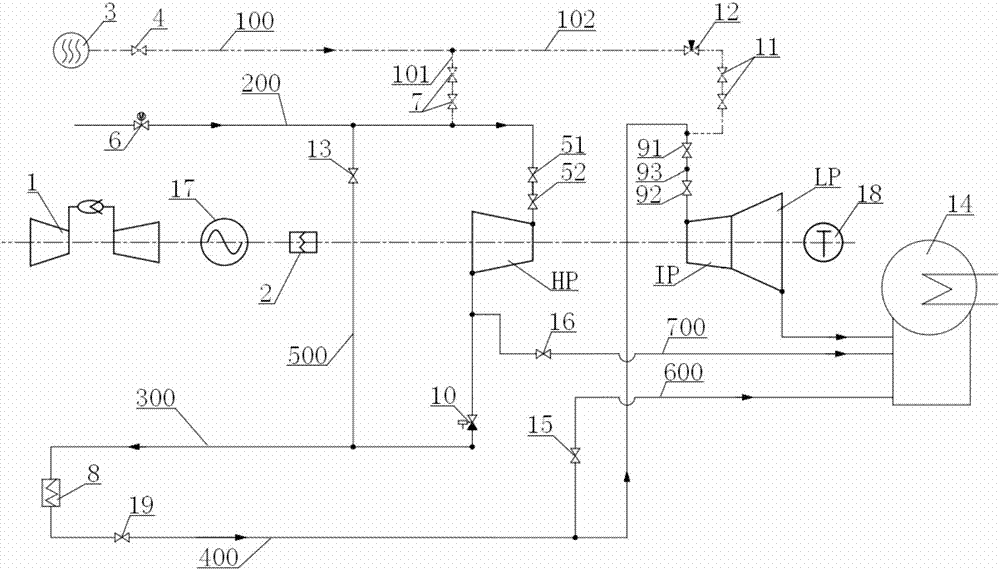

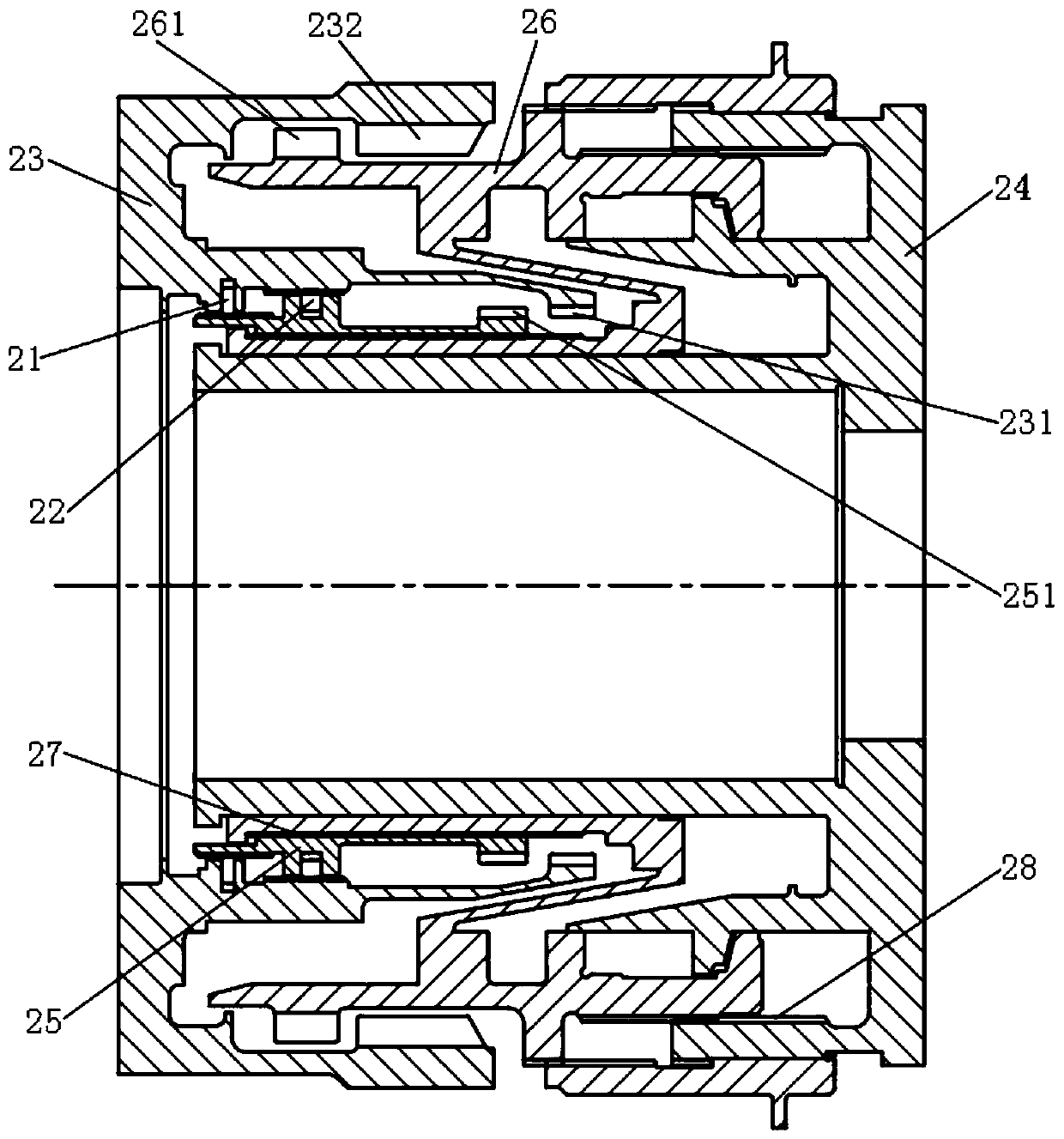

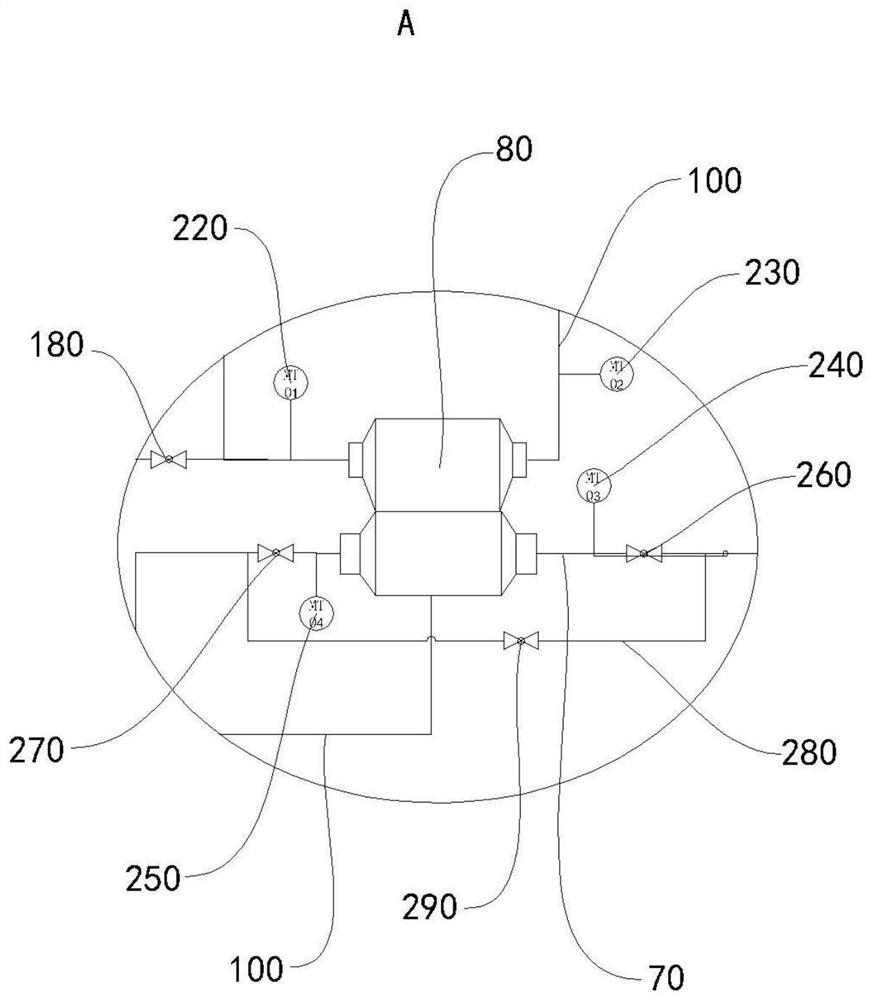

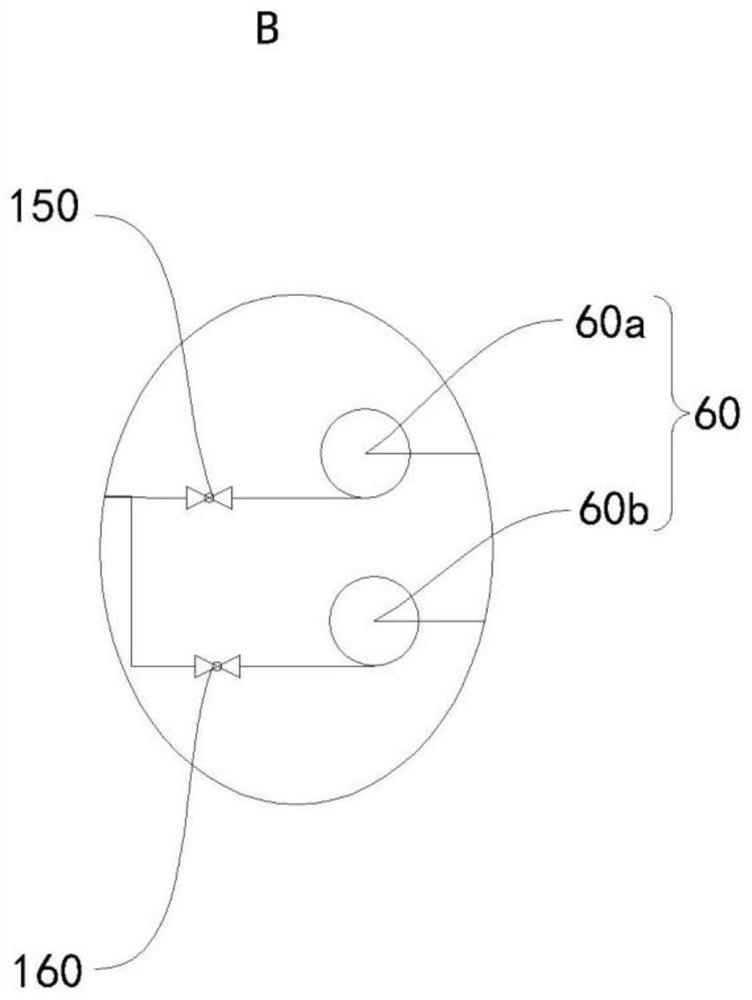

A combined cycle steam turbine quick-start pre-heating system and warm-up method thereof

ActiveCN108425707BSignificant progressRaise initial temperatureGas turbine plantsEngine startersHeating timeEngineering

The invention relates to the technical field of fuel gas-steam combined cycle systems, in particular to a preheating system quickly started by a combined cycle steam turbine, and a heating method thereof. The system comprises a fuel gas turbine, an electric generator, an automatic synchronizing clutch, the steam turbine and a heating gas source, wherein the steam turbine comprises a high-pressurecylinder, a middle-pressure cylinder and a low-pressure cylinder; the heating gas source is connected with a heating steam conveying pipeline leading to the high-pressure cylinder and the middle-pressure cylinder; and the automatic synchronizing clutch is the clutch provided with a primary pawl and a secondary pawl. The method comprises the steps of when the fuel gas turbine is static or the rotating speed of the fuel gas turbine is lower than the rotating speed of the steam turbine, accelerating the rotating speed of the steam turbine; when the rotating speed of the steam turbine is tended toexceed the rotating speed of the fuel gas turbine, engaging the automatic synchronizing clutch, and leading a heating steam; when the rotating speed of the steam turbine is accelerated and stabilizedat p r / min, driving the fuel gas turbine and the electric generator to rotate at the speed of p r / min, and starting to heat; and when the temperature of a middle-pressure rotor of the steam turbine reaches to the preset temperature or the heating time reaches to the preset time, finishing heating. The cold start time can be shortened.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD +2

Efficient energy-saving pulp dewatering and drying equipment

ActiveCN103438678BReduce drying costsLow costPulp de-wateringDrying gas arrangementsAir preheaterMicrowave

Owner:JIMEI UNIV

Fluidized bed dryer

InactiveCN109751836AReduces uneven dryingAvoid adding heat sourcesDrying solid materials with heatDrying gas arrangementsFluidized bed dryingEngineering

The invention relates to a drying device, in particular to a fluidized bed dryer. A fluidized bed body, a heater, an air blower, an induced draught fan and a cyclone separator are included; the two sides of the fluidized bed body are provided with a wet material inlet pipe and a dry material outlet pipe correspondingly; a bottom connection pipe of the fluidized bed body communicates with the heater which communicates with the air blower; a filter is arranged in a pipeline between the heater and the air blower; a top connection pipe of the fluidized bed body communicates with the cyclone separator; and a top outlet of the cyclone separator communicates with the induced draught fan. According to the fluidized bed dryer, the outer wall face of the wet material inlet pipe is sleeved with a boxbody, the inner wall of the box body and the outer wall of the wet material inlet pipe form a cavity, heat media flow through the cavity, wet materials are dried in advance, and therefore the defectsthat caking is caused when the wet materials enter a bed body in the prior art and drying unevenness is caused, and discharging of products is affected are reduced.

Owner:丹阳市宏光机械有限公司

An absorption heat pump refrigeration power cogeneration method

ActiveCN106170669BRaise initial temperatureReduce exhaust temperatureHeat pumpsSolubilitySteam power

Owner:湖北沄禾泽生态农业开发有限公司

Flue gas waste heat recycling system

PendingCN114593602ARaise initial temperatureKeep dryMaintainance of heating chambersFurnace typesFlue gasProcess engineering

The invention provides a flue gas waste heat recycling system. The flue gas waste heat recycling system comprises a firing kiln, a green body drying kiln, a desulfurizing tower and a spray tower drying furnace. High-temperature flue gas exhausted by the firing kiln is subjected to waste heat conduction through the first heat exchanger and is used as combustion-supporting air for fuel combustion of the spray tower drying furnace, so that the initial temperature and the internal energy of the combustion-supporting air are improved, the fuel in the spray tower drying furnace is more prone to combustion, and the combustion-supporting air volume and the fuel needed for generating the same heat and the same flue gas temperature are reduced; meanwhile, flue gas waste heat is conducted through the first heat exchanger and can also be used as air for drying the ceramic green bodies in the green body drying furnace, so that fuel consumed when the ceramic green bodies are dried is reduced; in addition, the flue gas in the middle of the firing process of the firing kiln is introduced into the second heat exchanger, heat guided out by the first heat exchanger is insufficient to supplement green body drying heat, the second heat exchanger can be used as the first heat exchanger for standby application, and the purposes of saving energy, reducing carbon emission and improving enterprise benefits can be achieved.

Owner:白兆金 +1

Heat energy reuse process based on waste heat of viscose staple fiber drying

ActiveCN104372551BImprove practicalityPromote energy saving and consumption reductionLiquid/gas/vapor removalTextile treatment machine arrangementsFiberThermal energy

The invention discloses a thermal energy recycling process based on viscose staple fiber drying waste heat. According to the process, waste heat of a viscose staple fiber dryer is treated in a classified mode and recycled. The viscose staple fiber dryer comprises a fiber preheating unit, a high-temperature waste heat unit and a waste heat drying unit, wherein the fiber preheating unit, the high-temperature waste heat unit and the waste heat drying unit are connected in sequence. The treatment process comprises classified treatment and recycling treatment. The design is quite reasonable; the defects that by the adoption of an existing waste gas drying and thermal energy utilization technology, classifications are unclear, the layout is not diversified, and the utilization rate is low are overcome; since waste gases in all regions of the dryer are classified according to the characteristics of the waste gases and recycled, the practicability of the waste gas drying and thermal energy utilization technology is improved, the problems of large thermal energy loss, high steam consumption, high production cost and the like in the prior art are also solved, energy conservation and consumption reduction work of an enterprise is promoted, and high social value and economic benefits are obtained.

Owner:YIBIN GRACE +2

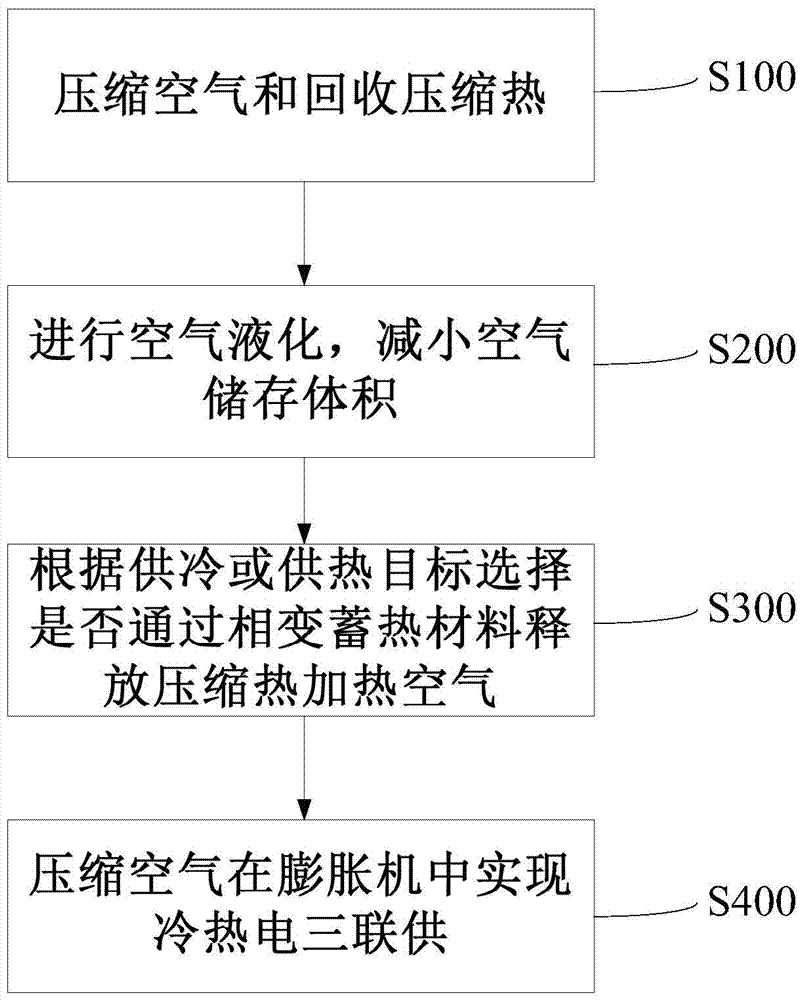

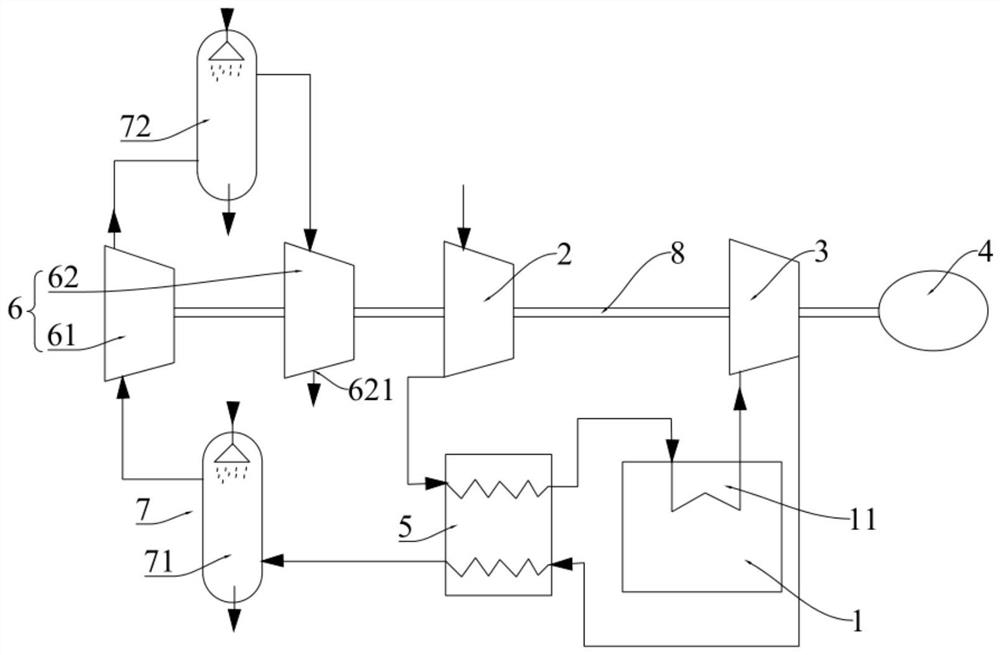

A combined cooling, heating and power supply device and method for supplying heat in summer and cooling in winter

ActiveCN105715518BIncrease temperatureIncrease working heat loadSolidificationLiquefactionAir compressionElectricity

The embodiment of the present invention discloses a combined cooling, heating and power supply device and method for supplying heat in summer and cold in winter, including a multi-stage air compression system, a solar phase change thermal storage system, an air liquefaction system and an expander combined cooling, heating and power supply system. The embodiment of the present invention provides a combined cooling, heating and power supply device and method for supplying heat in summer and cold in winter, and its method is based on liquid air energy storage technology. It utilizes low-priced low-cost electricity and waste electricity in power stations to provide compressed air, and the compressed air passes through during peak power consumption. The expander generates power, and the exhaust gas is used as a cold source / heat source to realize heating in winter and cooling in summer; at the same time, a solar phase change heat storage system is used to collect waste heat from the compressor and solar energy, which not only heats the working fluid to improve system efficiency, but also serves as a heat source for external supply hot water.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

Electricity-heat-electricity energy storage system and method

ActiveCN112539673ARaise initial temperatureHigh thermal efficiencyHeat storage plantsMachines/enginesElectric heatingProcess engineering

The invention discloses an electricity-heat-electricity energy storage system and method, and relates to the technical field of energy storage. The electricity-heat-electricity energy storage system comprises a heat storage device, a first air compressor, a turbine device and a generator, wherein the heat storage device is filled with a heat storage medium, the heat storage medium is silicon, during heat storage, silicon is converted into a liquid state from a solid state, during heat release, silicon is converted into a solid state from a liquid state, and a heat exchanger is further arrangedin the heat storage device; the first air compressor is used for compressing air to 0.15 MPa to 0.3 MPa, and the first air compressor is connected with an inlet of the heat exchanger, so that heat exchange between the air and the liquid silicon is facilitated; the turbine device is connected with an outlet of the heat exchanger; and the generator is connected with the turbine device. According tothe electricity-heat-electricity energy storage system, the thermodynamic conversion efficiency can be ensured, and the operation safety of the system can be improved.

Owner:SHANGHAI POWER EQUIP RES INST

An electric-thermal-electric energy storage system and method

ActiveCN112539673BRaise initial temperatureHigh thermal efficiencyHeat storage plantsMachines/enginesAir compressionLiquid state

The invention discloses an electric-thermal-electric energy storage system and method, and relates to the technical field of energy storage. The electric-thermal-electric energy storage system comprises: a heat storage device, a heat storage medium is contained in the heat storage device, and the heat storage medium is silicon, when the heat is stored, the silicon changes from a solid state to a liquid state, and when the heat is released, the silicon changes from a liquid state The first air compressor is used to compress the air to 0.15MPa‑0.3MPa, and the first air compressor is connected to the inlet of the heat exchanger, so that the air can be Liquid silicon conducts heat exchange; turbine device, which is connected to the outlet of the heat exchanger; generator, which is connected to the turbine device. The invention can not only ensure the thermal-dynamic conversion efficiency, but also improve the safety of system operation.

Owner:SHANGHAI POWER EQUIP RES INST

Pre-heating type solar water heater

ActiveCN106705458AEvenly loadedReduce volumeSolar heating energySolar heat devicesWater sourceSolar water

The invention relates to a pre-heating type solar water heater which comprises a pre-heating water tank; a plurality of heat collecting tubes are fixedly arranged on the upper part of the pre-heating water tank; the pre-heating water tank comprises a housing layer and a light-transmitting plate; a pre-heating cavity is formed between the light-transmitting plate and the housing layer; a light reflecting layer is arranged on the surface of the housing layer; the pre-heating water tank is connected with the heat collecting tubes through a connecting water tank; the connecting water tank comprises a water inlet cavity, a middle-temperature cavity and a high-temperature cavity; the bottom of the water inlet cavity is connected with a public water source; the top of the water inlet cavity communicates with the bottom of the pre-heating water tank; the bottom of the middle-temperature cavity communicates with the top of the pre-heating water tank; the top side wall of the middle-temperature cavity communicates with each heat collecting tube; the bottom of the high-temperature cavity is separately equipped with a low-temperature circulating tube and a high-temperature water inlet tube; the low-temperature circulating tube passes through the top of the middle-temperature cavity and extends to the bottom position of the middle-temperature cavity; the high-temperature water inlet tube communicates with the top of the middle-temperature cavity; the other end of the high-temperature water inlet tube extends to a top position of the high-temperature cavity; and a used water drainage tube is further arranged on the top of the high-temperature cavity.

Owner:JIANGSU SUNNIC SOLAR ENERGY INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com