Combined heat and carbon dioxide supply system for greenhouse

A carbon dioxide and greenhouse technology, applied in the field of greenhouse agriculture, can solve the problems of unstable wind power generation, unstable system, and high thermal efficiency, and achieve the effects of facilitating purification and dust removal, realizing automation, and improving initial temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

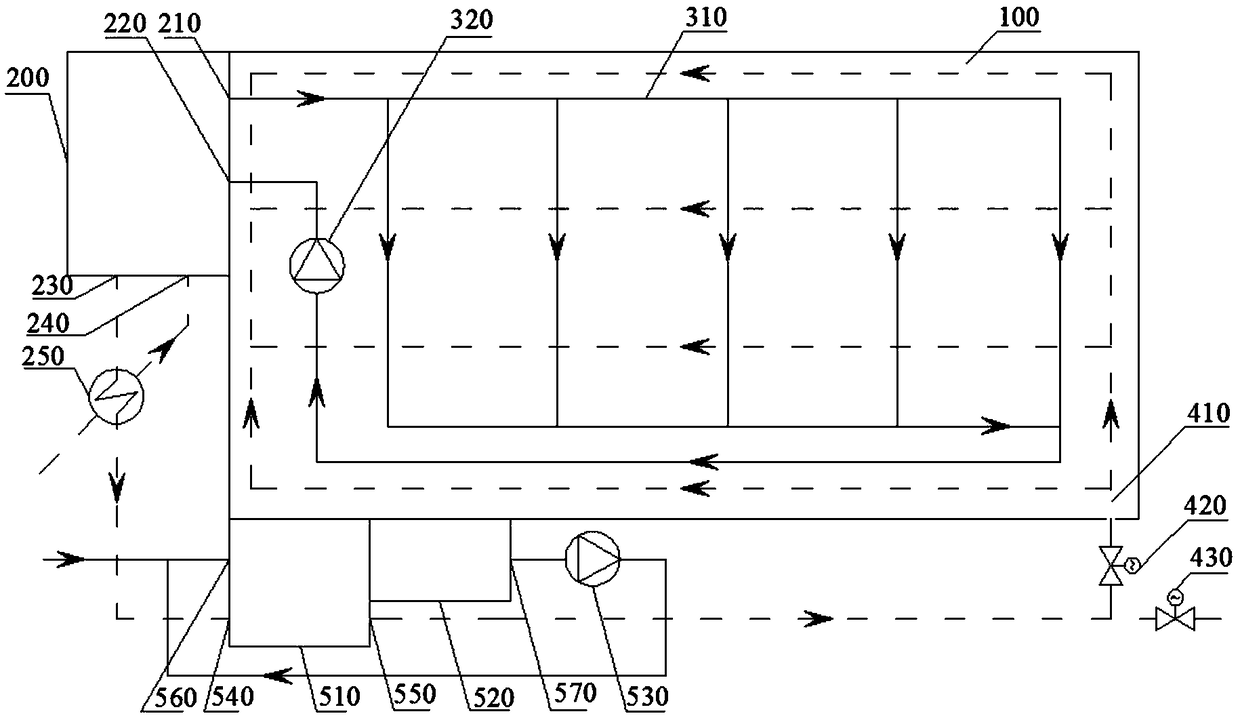

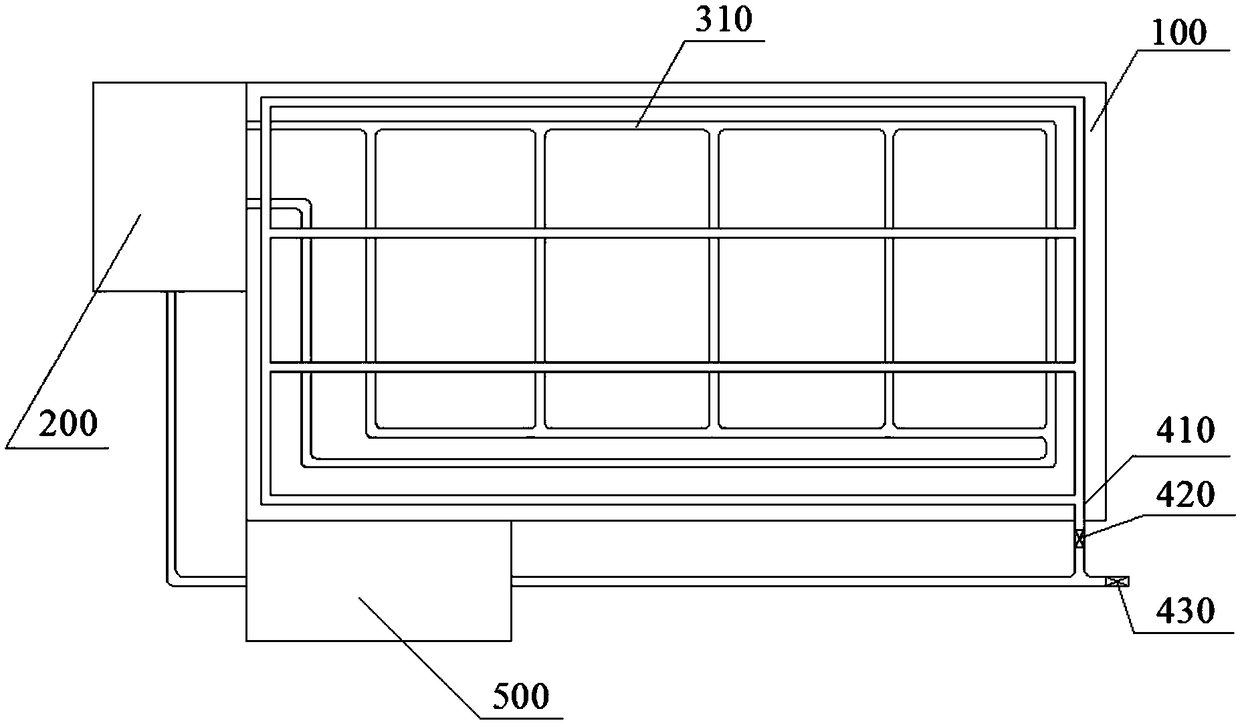

[0025] Such as figure 1 and figure 2 As shown, a greenhouse combined heating and carbon dioxide supply system includes a biomass boiler 200, a heat exchanger 250, a gas purification room 500 and a control system; the biomass boiler 200 is provided with a steam outlet 210 and a liquid water inlet 220 and the flue gas outlet 230, the inside of the greenhouse 100 is provided with a closed-loop heating pipe 310, and the steam outlet 210 is sequentially connected to the return pump 320 and the liquid water inlet 220 through the heating pipe 310; the inside of the greenhouse 100 is provided with a carbon injection pipe 410 , the flue gas outlet 230 is sequentially connected with the heat exchanger 250 , the gas cleaning chamber 500 and the carbon injection tube 410 . The car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com