Quick combined cycle steam turbine starting and warming system and method

A fast-start, combined cycle technology, applied in the field of gas-steam combined cycle systems, can solve problems such as low thermal efficiency and increase power generation costs, increase peak shaving capacity and power generation, eliminate clutch damage, and shorten cold start requirements. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1 of the present invention provides a method for quickly starting and warming up a combined cycle steam turbine. The method for quickly starting and warming up a combined cycle steam turbine in Embodiment 1 is suitable for cold start of a single-shaft combined cycle unit equipped with a clutch. The shaft combined cycle unit is equipped with a generator between the gas turbine and the steam turbine. One end of the generator shaft is connected to the rotor shaft of the gas turbine, and the other end of the generator shaft is connected to the rotor shaft of the steam turbine through a clutch. The gas turbine and the steam turbine share the same steam turbine barring device, and the steam turbine barring device is connected with the steam turbine. The capacity of the steam turbine barring device in the first embodiment should be capable of driving the steam turbine, the generator and the gas turbine to rotate at the same time.

[0054] The clutch in the first emb...

Embodiment 2

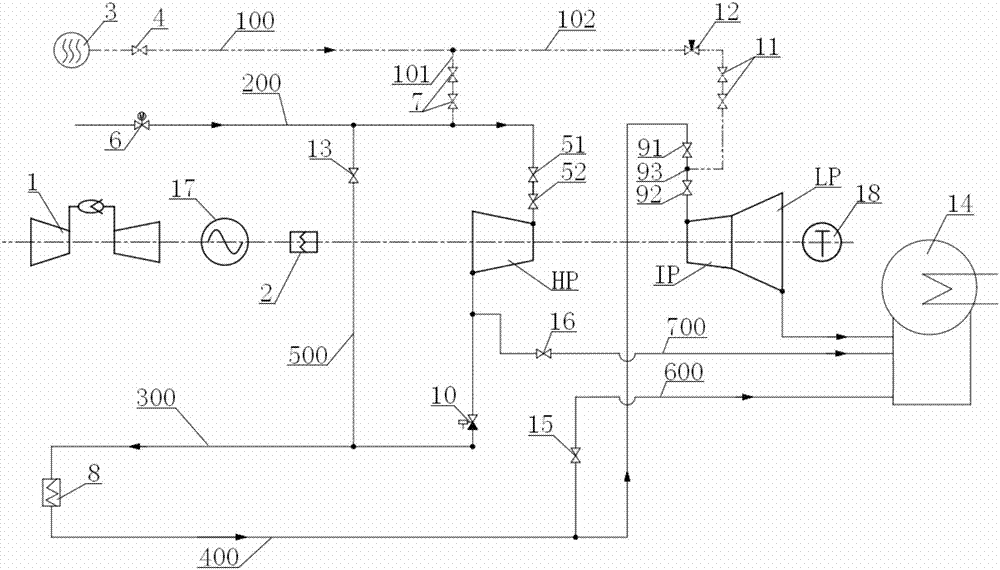

[0066] Such as figure 1 As shown, Embodiment 2 provides an embodiment of the combined cycle steam turbine quick start warm-up system of the present invention. The system for quickly starting and warming up a combined cycle steam turbine in Embodiment 2 can be used to realize the method for quickly starting and warming up a combined cycle steam turbine described in Embodiment 1.

[0067] Specifically, the combined cycle steam turbine quick-start warm-up system of the second embodiment includes a warm-up steam source 3 and a coaxially arranged gas turbine 1, a generator 17, a clutch 2 and a steam turbine, that is, one end of the generator 17 rotating shaft and The rotor shaft of the gas turbine 1 is connected, and the other end of the rotating shaft of the generator 17 is connected with the rotor shaft of the steam turbine through the clutch 2 . The steam turbine is connected with the steam turbine barring device 18, and the steam turbine can be dragged to rotate by the steam t...

Embodiment 3

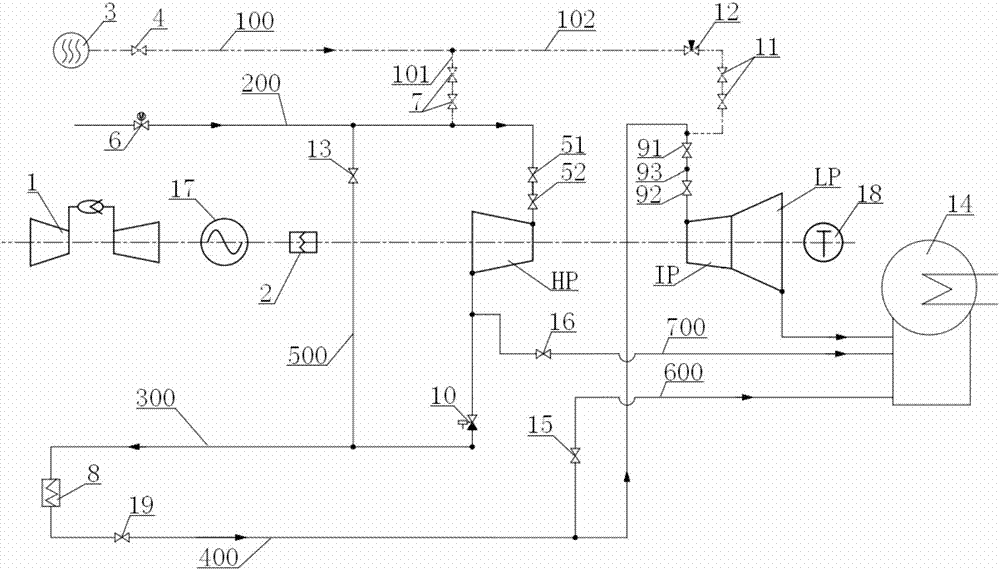

[0090] Such as figure 2 As shown, the third embodiment provides the second embodiment of the combined cycle steam turbine quick start warm-up system of the present invention. The third embodiment is basically the same as the second embodiment, and the similarities will not be repeated. The difference is that in the third embodiment, a gate valve 19 is provided on the medium-pressure steam inlet pipeline 400 upstream of the medium-pressure steam inlet valve group. , the warm-up steam delivery pipeline 100 communicates with the medium-pressure steam inlet pipeline 400 through the medium-pressure delivery pipeline 102 between the gate valve 19 and the medium-pressure steam inlet valve group. When the gate valve 19 is closed and the medium-pressure steam inlet valve group is opened, the warm-up steam in the warm-up steam delivery pipeline 100 can pass through the medium-pressure delivery pipeline 102 into the medium-pressure steam inlet pipeline 400, and then pass through the med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com