Turbine stator structure for helium turbine

A technology of stator structure and turbine, which is applied to stators, mechanical equipment, engine components, etc., can solve the problems of inconvenient disassembly and assembly, low efficiency of helium gas work, and the overall length of the turbine stator structure, so as to facilitate disassembly and assembly and improve efficiency. , the effect of shortening the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

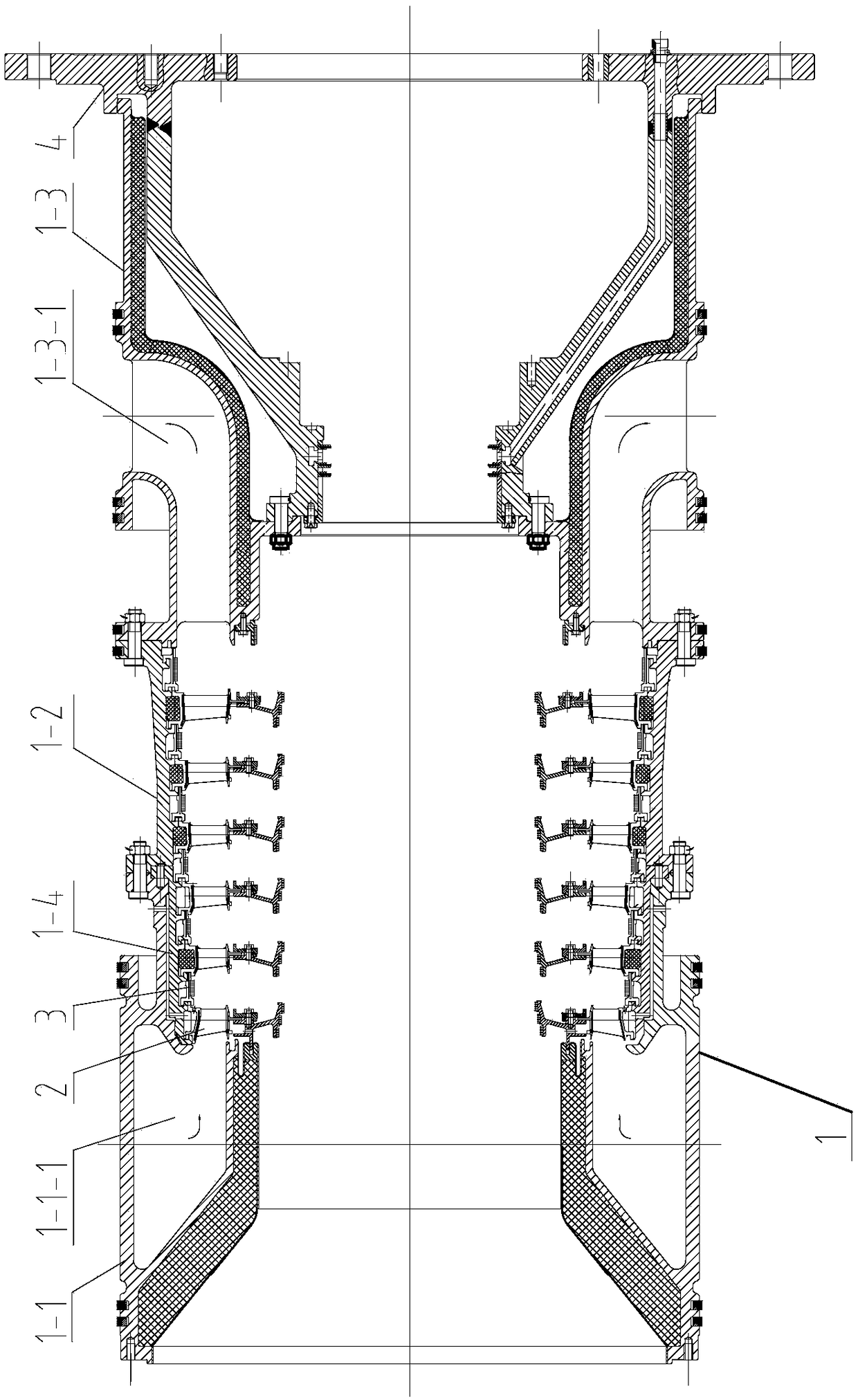

[0020] Specific implementation mode one: combine figure 1 Describe this embodiment, the turbine stator structure for helium gas turbine described in this embodiment includes a turbine casing 1, a guide 2, a sealing guard ring 3 and a bearing housing 4, and the bearing housing 4 extends into the The tail of the turbine casing 1 is fixedly connected, and the seal retaining ring 3 and multiple sets of guides 2 are fixed in the card slot inside the turbine casing 1;

[0021] The turbine case includes an intake case 1-1, a turbine case 1-2 and an exhaust case 1-3, and the front and rear ends of the intake case 1-1 and the turbine case 1-2 are Flanges are respectively provided. The front end of the exhaust casing 1-3 and the upper middle of the interior are respectively provided with flanges. The front end of the bearing housing 4 is provided with a flange, and the rear end is provided with a clip groove;

[0022] The flange at the rear end of the intake casing 1-1 and the flange ...

specific Embodiment approach 2

[0026] Specific implementation mode two: combination figure 1 , 2 and 4 illustrate this embodiment,

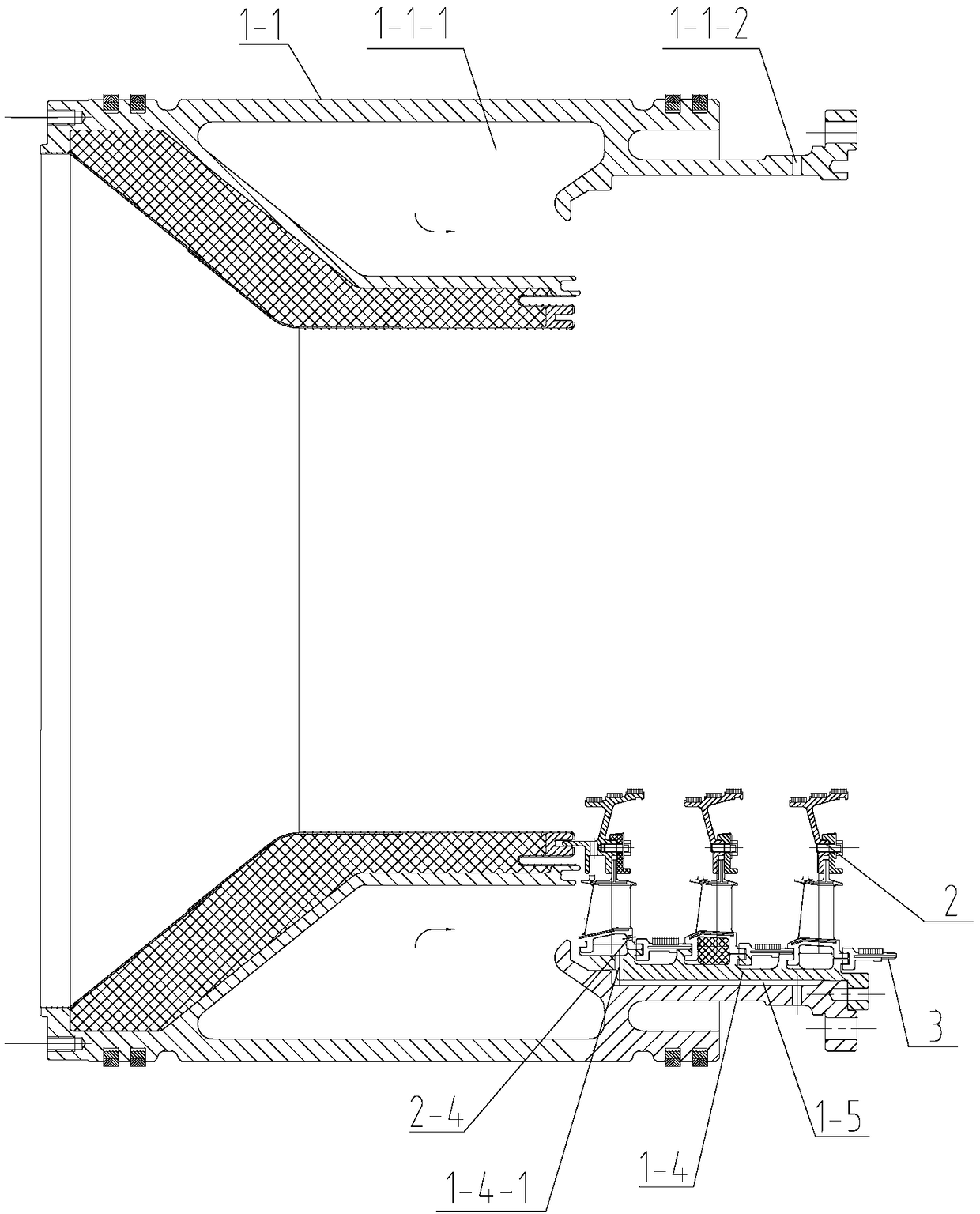

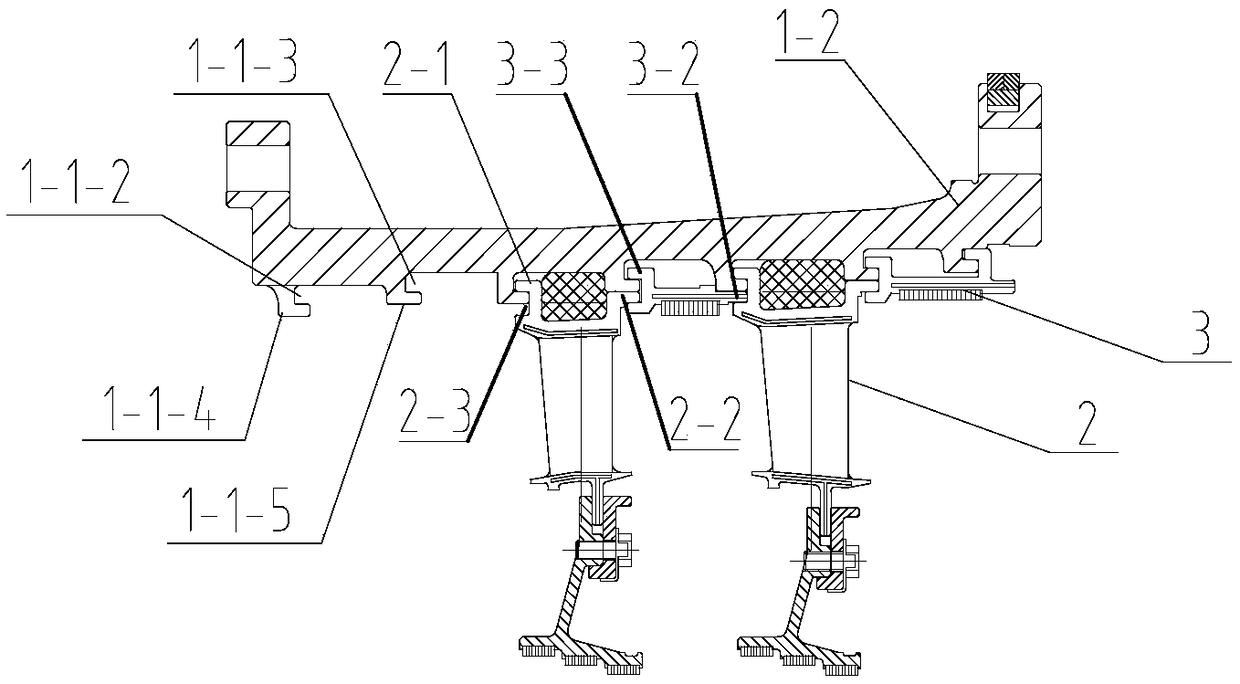

[0027] Such as figure 2 As shown: an inner casing 1-4 is also arranged inside the air intake casing 1-1, and the front 3-stage guide group and the front 3-stage sealing guard ring 3 are installed alternately in the inner casing 1 -4 in the card slot, and fixed inside the intake casing 1-1 through the inner casing 1-4;

[0028] Such as Figure 4 Shown: the tail end of the inner casing 1-4 has a flange; as figure 2 As shown: the tail end of the intake casing 1-1 has a pin hole, the front end of the inner casing 1-4 is stuck in the card slot in the intake casing 1-1, and the flange at the tail end is fixed on the intake casing by pins. In the pin hole at the tail end of the air casing 1-1;

[0029] Such as figure 2 As shown: the fourth cooling gas passage 1-5 is formed between the air intake casing 1-1 and the inner casing 1-4.

[0030] The inner casing is arranged in ...

specific Embodiment approach 3

[0032] Specific implementation mode three: as figure 2 with Figure 5 As shown: the air intake casing 1-1 described in this embodiment also has two air intake holes, and the air intake holes are connected with the air intake channel 1- 1-1 communicate; the exhaust casing 1-3 is provided with an exhaust passage 1-3-1 in the circumferential direction.

[0033] The high-temperature helium gas enters the air intake channel through the air intake hole, guides the flow through the guide set, and then acts on the moving blades of the rotor.

[0034] Other compositions and connection methods are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com