Inside and outside burning coal integrative combined cycle generation system and method

A combined cycle power generation and coal-fired technology, applied in steam generation, steam generation devices, gas turbine devices, etc., can solve the major environmental problems without considering the control of CO, limited efficiency improvement, low power generation efficiency, etc., to achieve superior environmental protection, The effect of saving compression power consumption and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] specific implementation

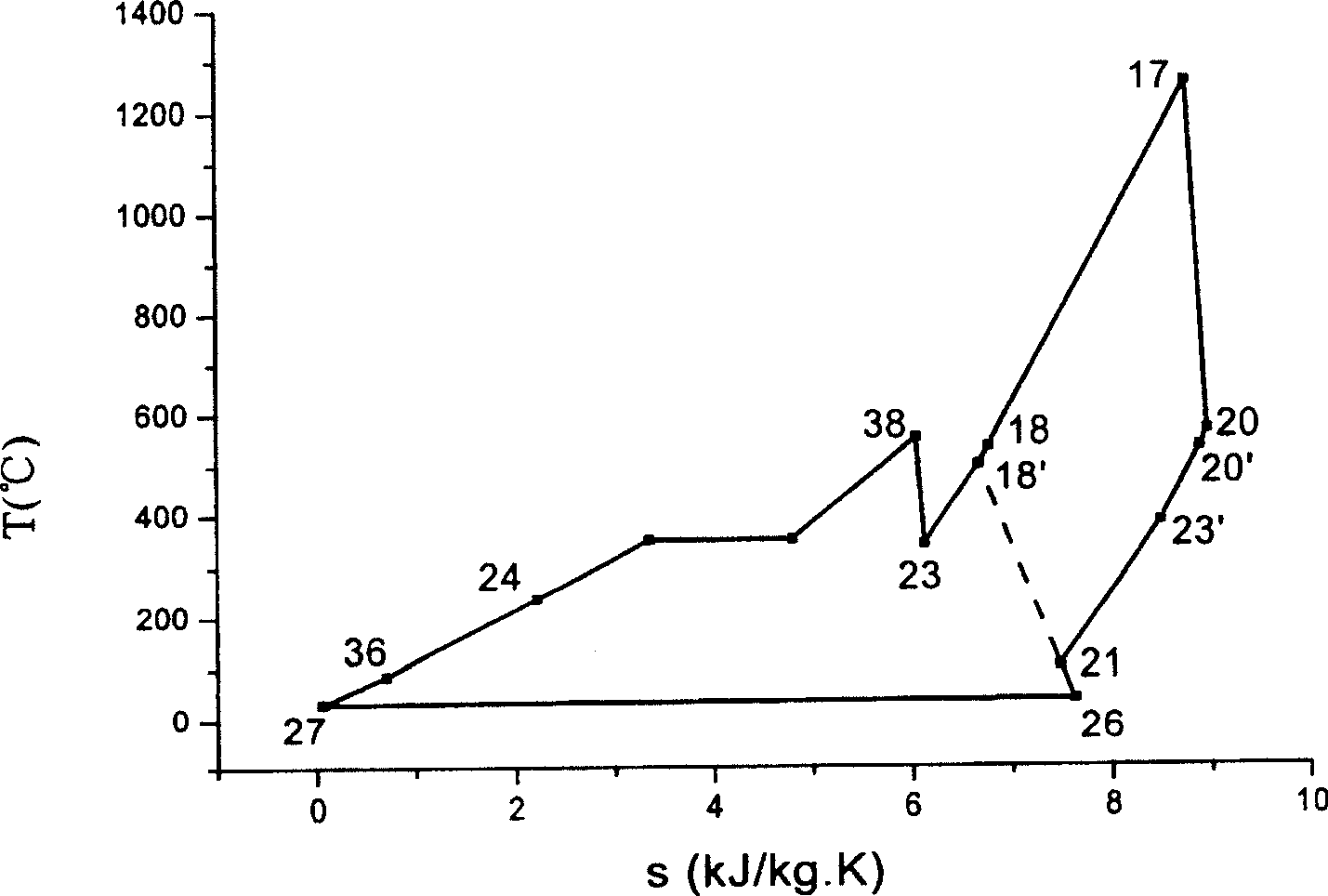

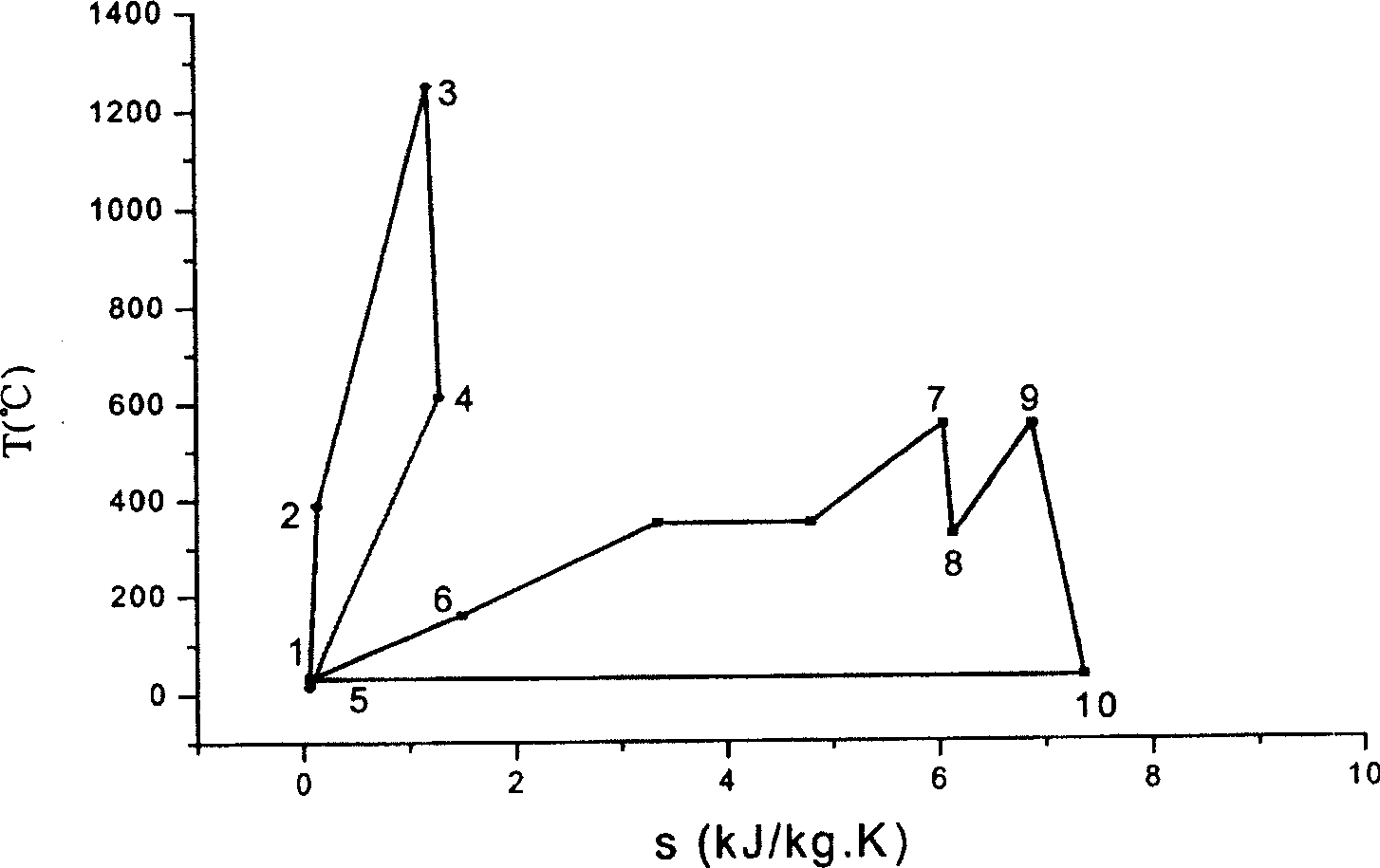

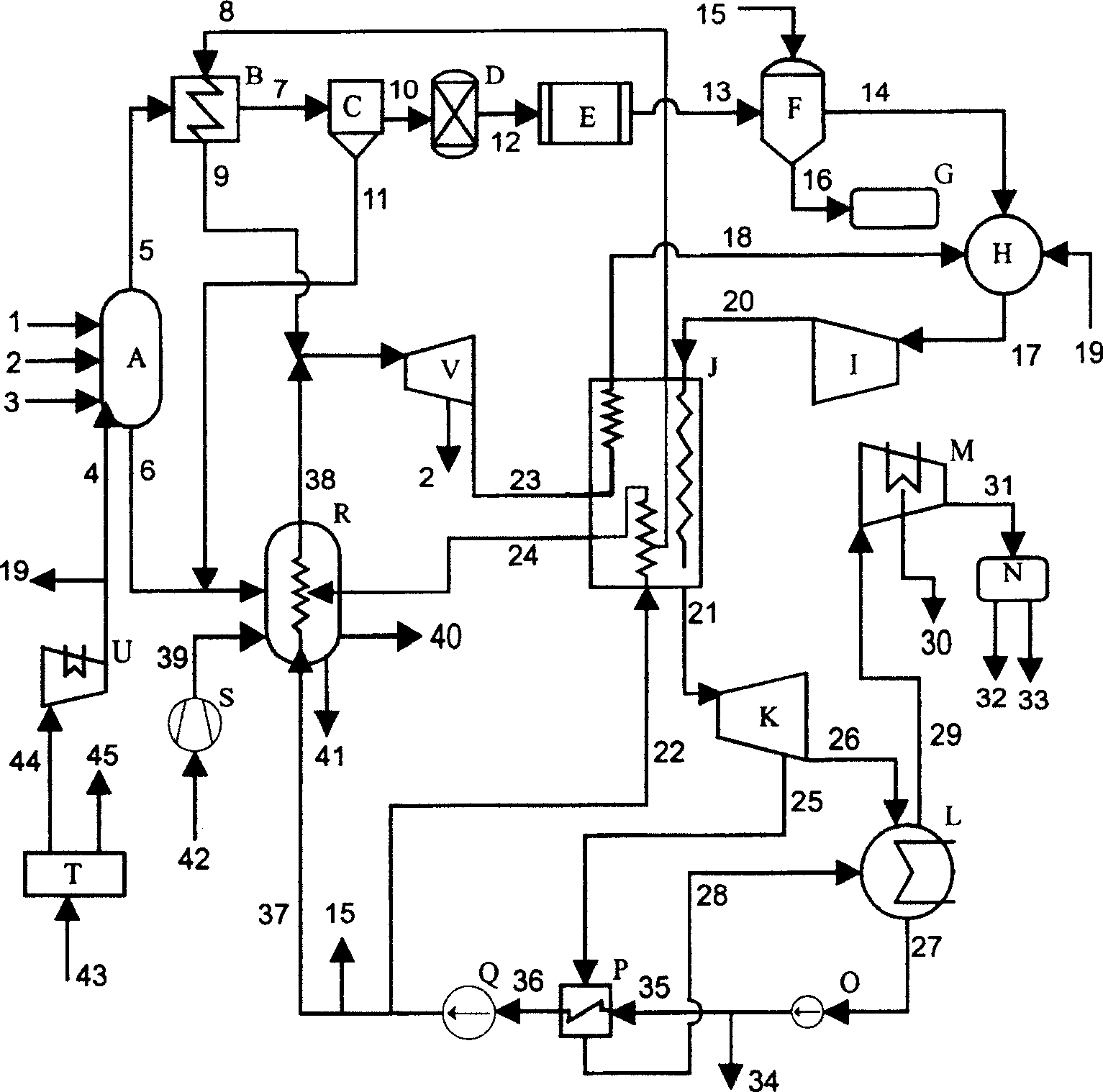

[0054] The T-s figure of new cycle of the present invention sees figure 1 (points in the figure and image 3 corresponding to the logistics serial number). The heat absorption process is divided into two stages: 24-38 is heating by external combustion (including the heating of water vapor by semi-coke combustion and the heating of water vapor by high-temperature gas), and 18-17 is heating by internal combustion; the work process is divided into three stages. Sections: 38-23 are high-pressure steam turbines, 17-20 are high-temperature gas turbines (steam and CO 2 mixed working fluid), 21-26 are cryogenic gas turbines (steam and CO 2 Mixed working fluid); the exothermic process is 26-27; the temperature rise of the feed water pressurization process is low, and it is 27 points and 36 points in the figure; the process 27-36, 36-24, 23-18 is the feed water reheating ( The heat source is low-temperature gas turbine pumping), feed water preheating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com