Efficient energy-saving pulp dewatering and drying equipment

A drying equipment, high-efficiency and energy-saving technology, applied in the direction of pulp dehydration, progressive dryer, drying solid materials, etc., can solve the problems of small footprint of energy utilization equipment, difficult to control product quality, high equipment maintenance costs, etc., to achieve improvement Production efficiency and energy utilization, high energy utilization efficiency, the effect of high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] specific implementation plan

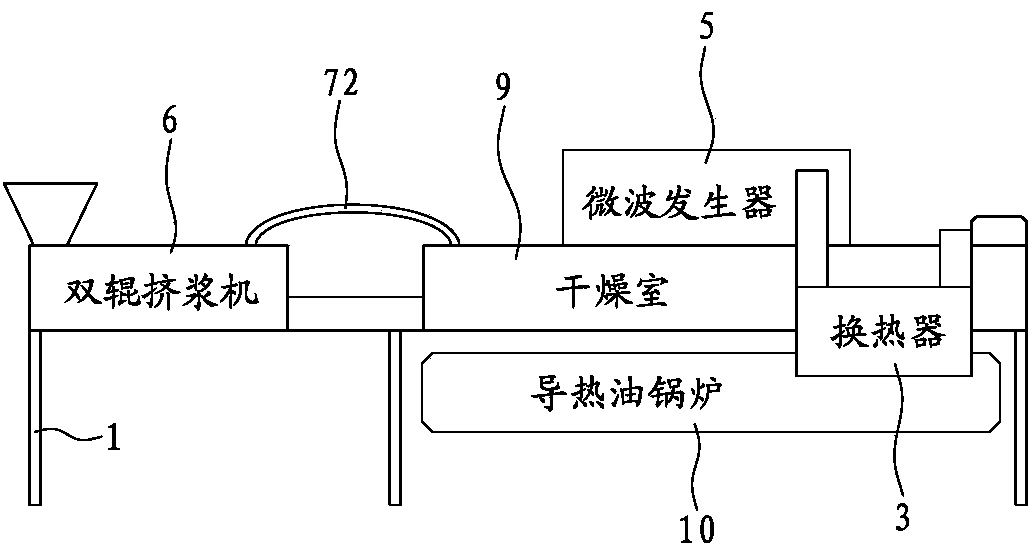

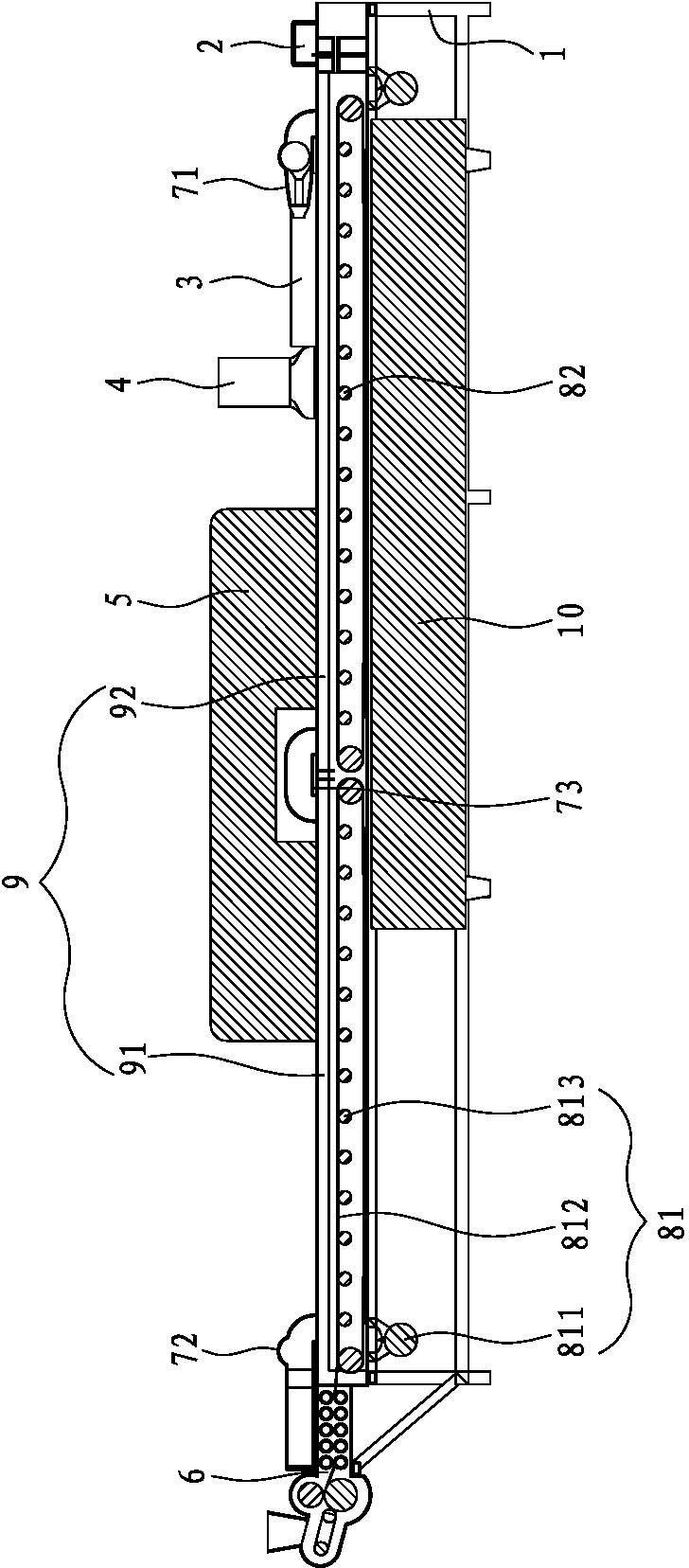

[0035] Such as figure 2 , Figure 3A , Figure 3B As shown, the present invention is a high-efficiency and energy-saving pulp dehydration and drying equipment, which mainly consists of a frame 1, a pulp cutting mechanism 2, a heat exchanger 3, an air preheater 4, a microwave generator 5, and a double-roll press 6 , Hot air circulation pipes 71, 72, 73, material transportation systems 81, 82, drying chamber 9, heat transfer oil boiler 10, etc.

[0036] Described drying chamber 9 is divided into two sections, and it is made of first drying chamber 91 and second drying chamber 92. The first drying chamber 91 and the second drying chamber 92 are connected to each other and are installed in the middle of the frame 1. The two sections of drying chambers are separated by partitions, and hot air circulates between the first drying chamber 91 and the second drying chamber 92. The pipe 73 communicates. Material transport systems 81 and 82 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com