Constant-temperature air storage system applied to compressed air energy storage power generation system

A technology for compressed air energy storage and power generation systems, applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc. Functional capacity and other issues, to achieve the effect of increasing energy storage efficiency, increasing working capacity, and improving energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation of the present invention will be described in further detail below in conjunction with the examples. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

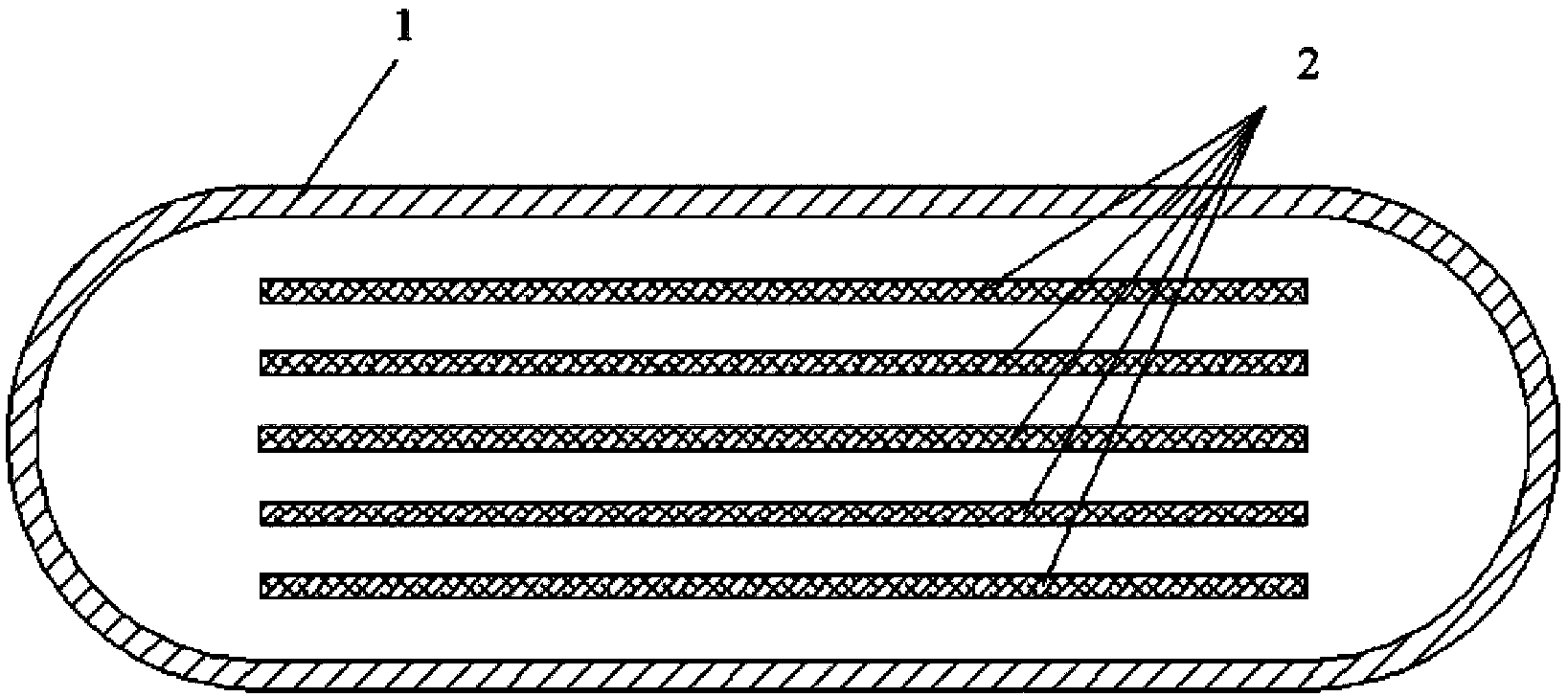

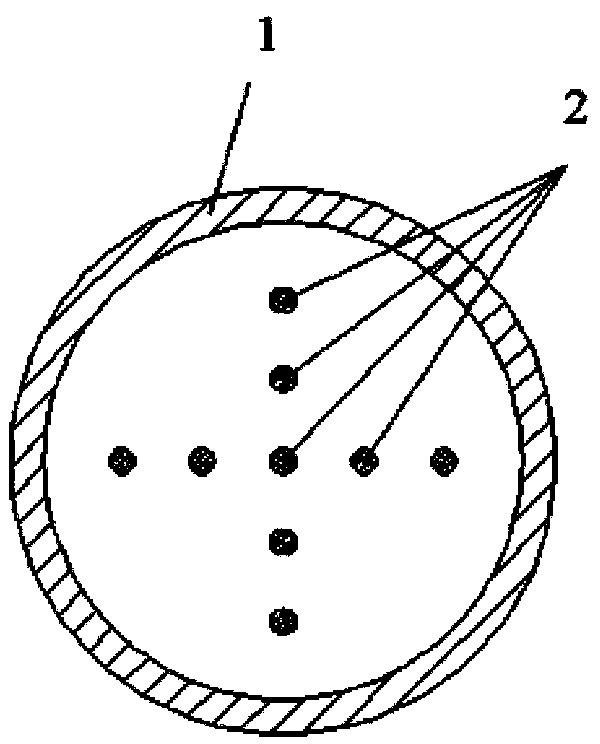

[0027] The constant temperature gas storage system applied to the compressed air energy storage power generation system of the present invention includes a gas storage device 1, which further includes a heat storage device 2 arranged in the gas storage device 1;

[0028] The heat storage device 2 is a phase-change heat storage working medium, or a large specific heat capacity (specific heat capacity greater than 0.5 kJ / kgk) heat storage working medium, or a combination of the two, and is packaged by a packaging structure to form a heat exchange structure.

[0029] The gas storage device 1 of the present invention is used to store high-pressure air of the compressed air energy storage power generation system; the heat storage dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com