Chemical looping combustion device and method based on tower bubbling fluidized bed fuel reactor

A technology of fuel reactor and bubbling fluidized bed, which is applied in the direction of fluidized bed combustion equipment, combustion method, fuel burned in molten state, etc., which can solve the problem of reduced chemical chain combustion efficiency of solid fuel, unfavorable gas-solid contact, and reduced reaction Efficiency and other issues to achieve the effect of improving gas-solid mixing, inhibiting the growth of bubbles, and ensuring combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

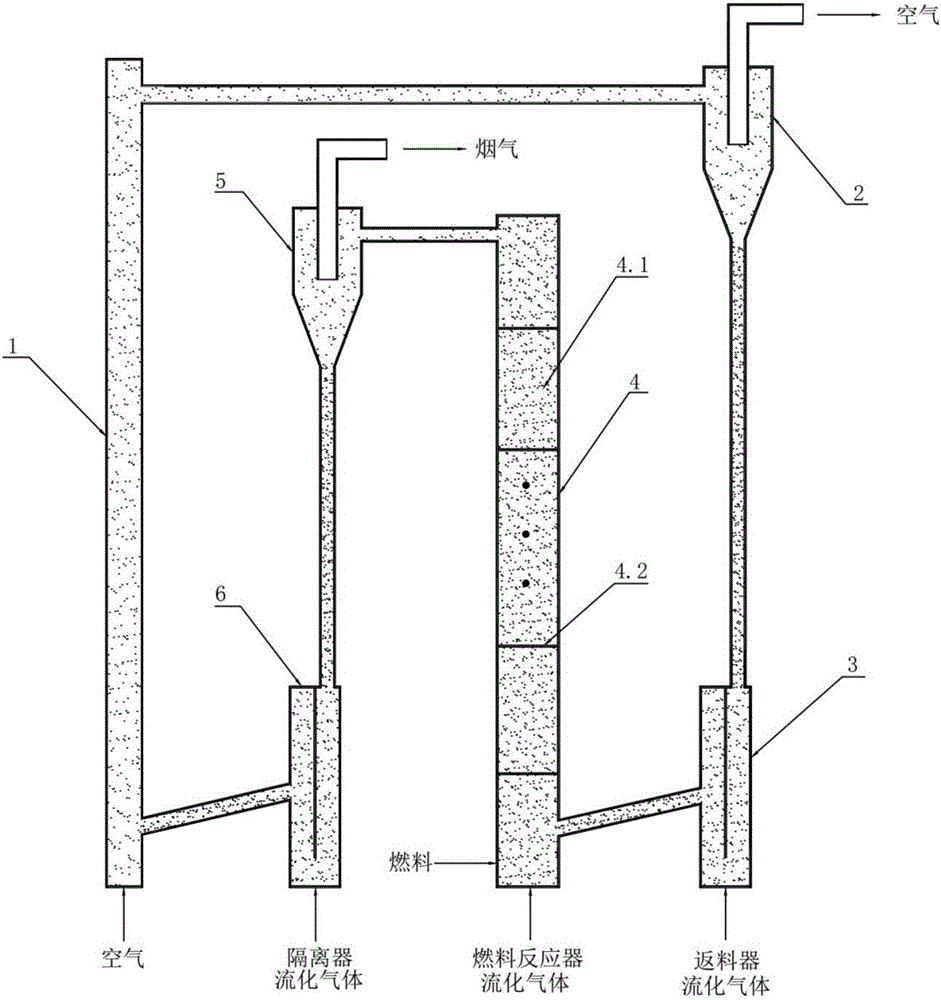

[0036] A method for a chemical chain combustion device based on a tower-type bubbling fluidized bed fuel reactor is that the fuel is not directly contacted and combusted with air, and the fuel is gas fuel. Gas fuels are reducing gases, including CO, H 2 and CH 4 and other gaseous fuels containing hydrocarbons. The gas fuel enters the tower fuel reactor 4, and the oxidation-reduction reaction is alternately cyclically carried out between the air reactor 1 and the tower fuel reactor 4 through the oxygen carrier, so as to realize the combustion of the gas fuel, and the oxygen carrier includes Various oxygen carrier particles such as nickel-based, iron-based, and copper-based; the specific method includes the following steps:

[0037] 1) Oxidation reaction: the fluidizing gas enters the tower fuel reactor 4 through the fuel reactor fluidizing gas inlet at the bottom of the tower fuel reactor 4, and the gaseous fuel enters the tower fuel reactor 4 through the fuel inlet on the bo...

Embodiment 2

[0044] A method for a chemical chain combustion device based on a tower-type bubbling fluidized bed fuel reactor is that the fuel is not directly contacted and combusted with air, and the fuel is a solid fuel. Solid fuels are solid fuels containing hydrocarbons, including coal, biomass, and domestic sludge. The solid fuel enters the tower fuel reactor 4, and the oxidation-reduction reaction is carried out alternately between the air reactor 1 and the tower fuel reactor 4 through the oxygen carrier, so as to realize the combustion of the solid fuel, and the oxygen carrier includes Various oxygen carrier particles such as nickel-based, iron-based, and copper-based; the specific method includes the following steps:

[0045] 1) gasification reaction: the fluidizing gas enters the tower fuel reactor 4 through the fuel reactor fluidizing gas inlet at the bottom of the tower fuel reactor 4, and the solid fuel enters the tower through the fuel inlet on the bottom side of the tower fue...

Embodiment 3

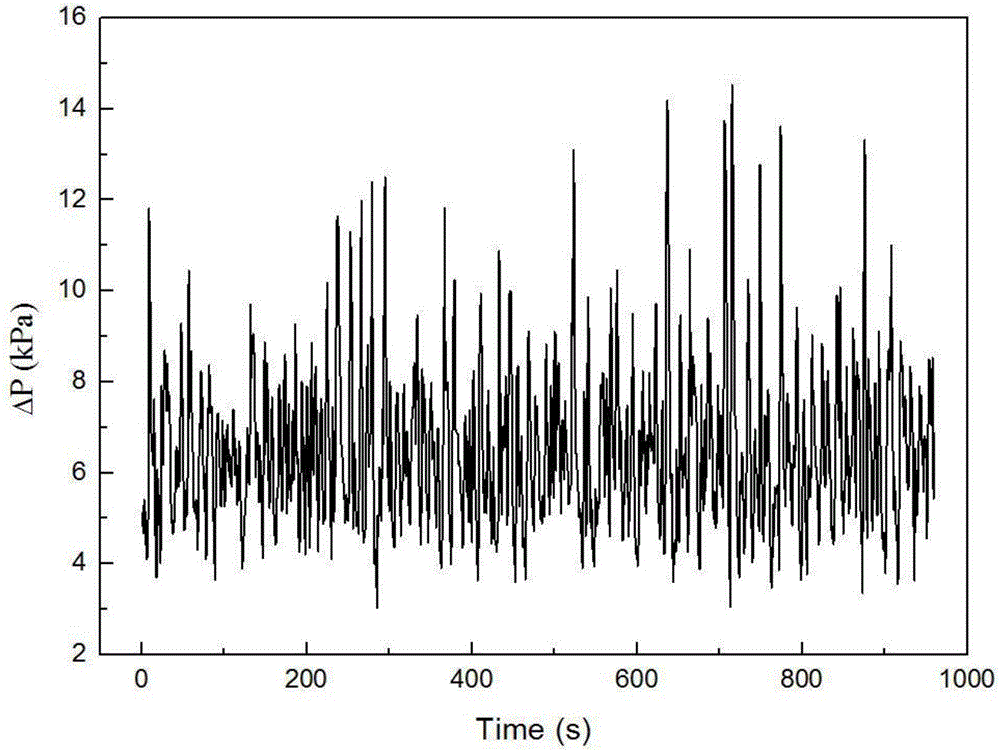

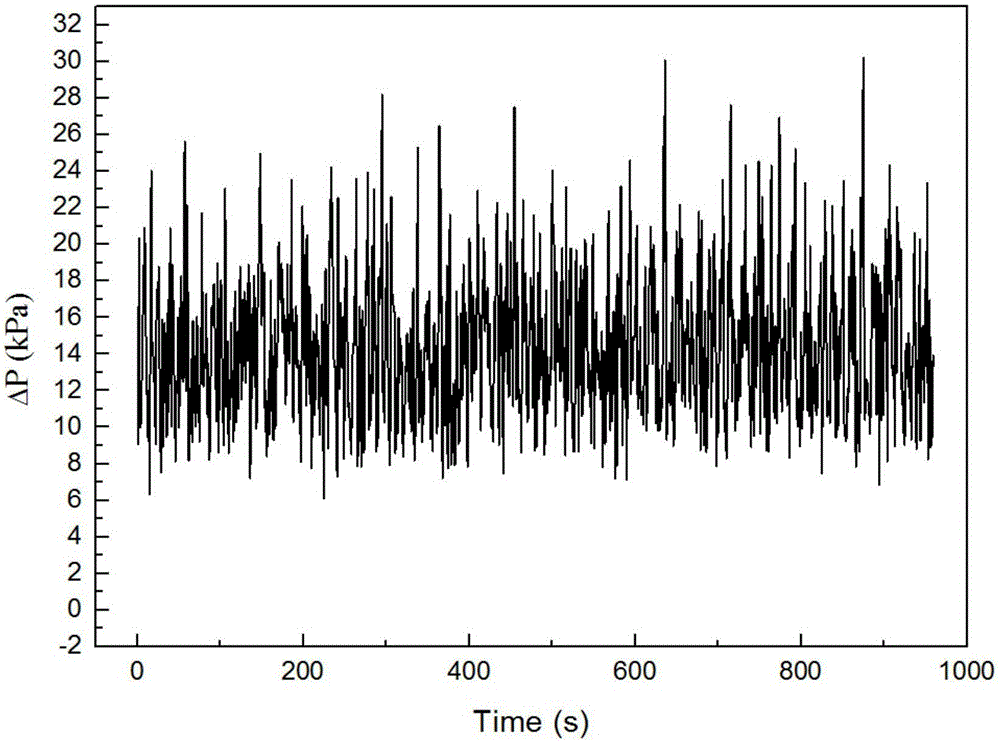

[0055] Quartz sand was used instead of oxygen carrier particles to carry out cold circulation experiments at room temperature. The particle size of quartz sand was 0.1-0.3 mm. Four independent air distribution baffles were set in the tower fuel reactor along the height direction. The fuel reactor is divided into five chambers, through figure 2 , image 3 The pressure drop curve of the bed found that the pressure fluctuated within a certain range with the passage of time, and the mean value was stable around a certain fixed value. This shows that the material circulation in the fluidized bed is in good condition, and the materials in the air reactor and the fuel reactor reach a dynamic balance. And during the circulation process, no obvious plug flow and throttling phenomenon were observed in the tower fuel reactor, the flow was uniform, and the gas-solid mixing was good.

[0056] In summary, the chemical chain combustion device and method based on a tower bubbling fluidized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com