Device for separating carbon dioxide through chemical-looping combustion in coal pressurizing high-density recirculating fluidized bed

A circulating fluidized bed and chemical looping combustion technology, which is applied in fluidized bed combustion equipment, indirect carbon dioxide emission reduction, fuel burning in a molten state, etc., can solve problems that have not yet been obtained, increase the attainment rate, and improve the gasification reaction rate , the effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

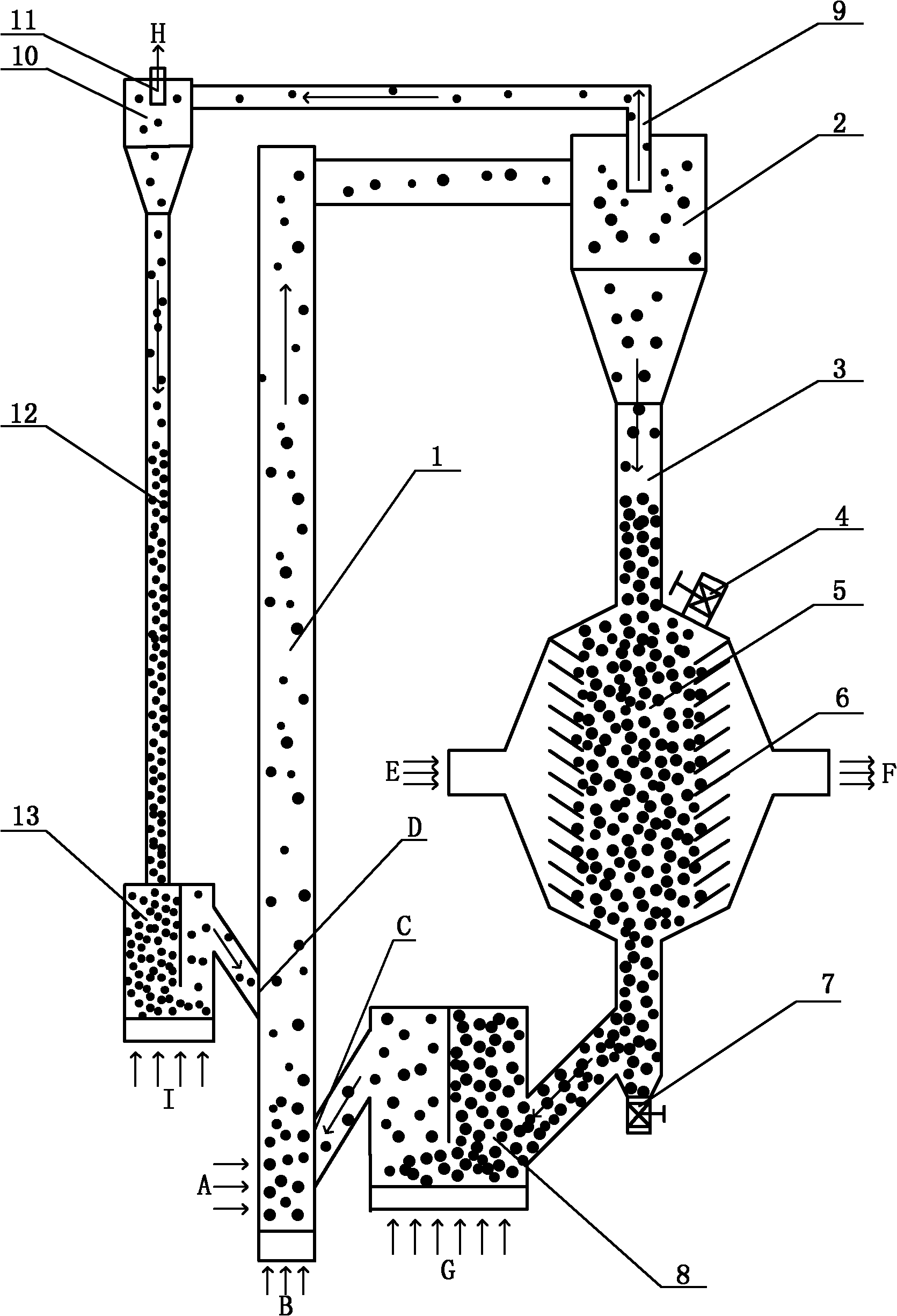

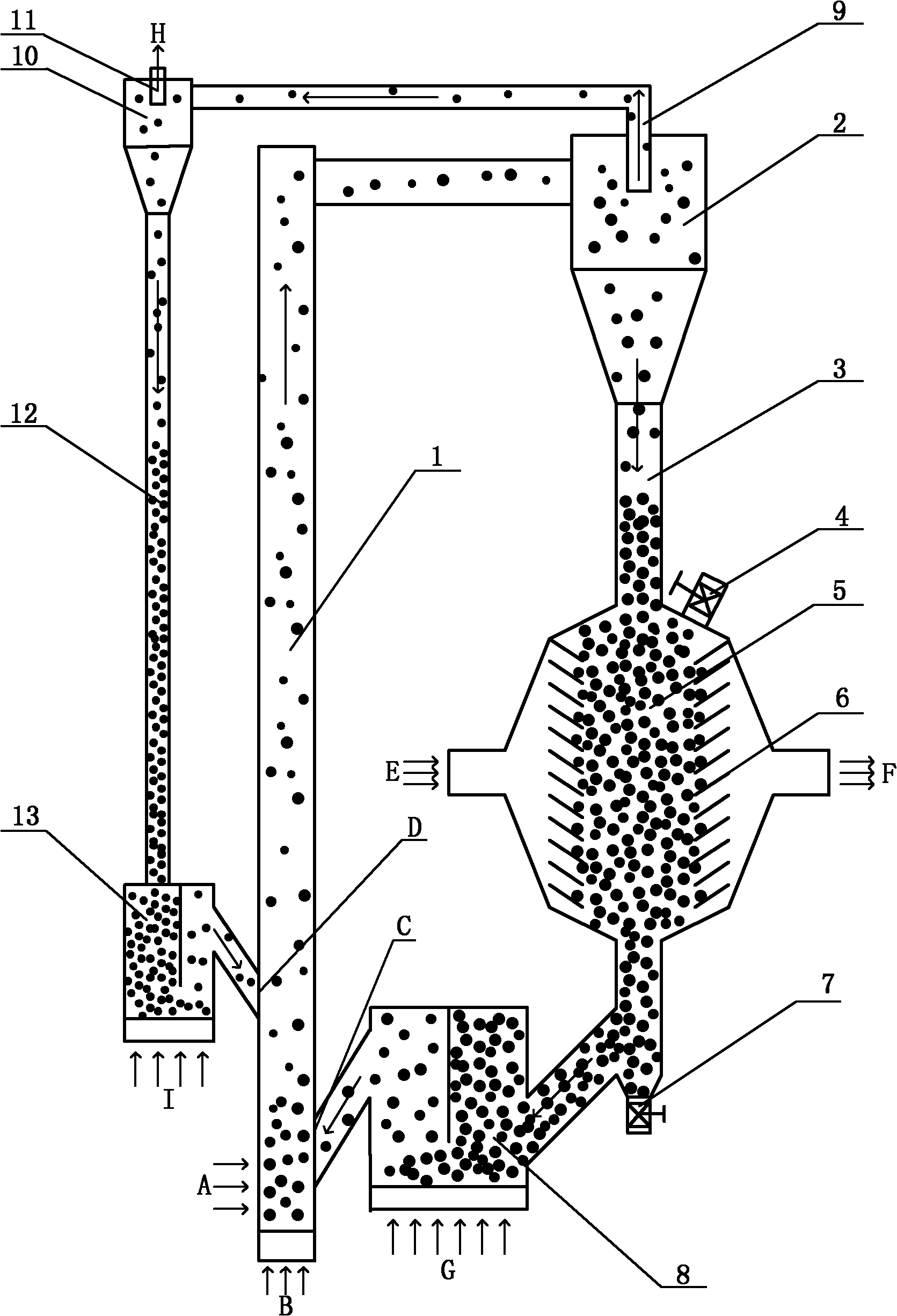

[0023] The device for separating carbon dioxide by chemical looping combustion of coal in a pressurized high-density circulating fluidized bed provided by the present invention includes a pressurized high-density circulating fluidized bed fuel reactor 1, a primary cyclone separator 2, a primary material leg 3, Fresh oxygen carrier particle feeder 4, cross-flow moving bed air reactor 5, grid plate 6, deactivated oxygen carrier particle discharger 7, primary return feeder 8, primary exhaust pipe 9, secondary The primary cyclone separator 10, the secondary exhaust pipe 11, the secondary material leg 12 and the secondary feeder 13.

[0024] The device for separating carbon dioxide by chemical looping combustion in a pressurized high-density circulating fluidized bed of coal consists of a two-stage circulation loop: the upper part of the pressurized high-density circulating fluidized bed fuel reactor 1 communicates with a primary cyclone separator 2, The lower part of the primary c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com