Magnetic oxygen carrier based solid fuel chemical-looping combustion system and technology

A technology of chemical looping combustion and solid fuel, which is applied in the direction of fluidized bed combustion equipment, fuel for combustion in a molten state, and combustion methods, etc. It can solve the problems of difficult separation of solid mixtures, low transfer volume and utilization efficiency of oxygen carriers, and achieve The effect of effective separation and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

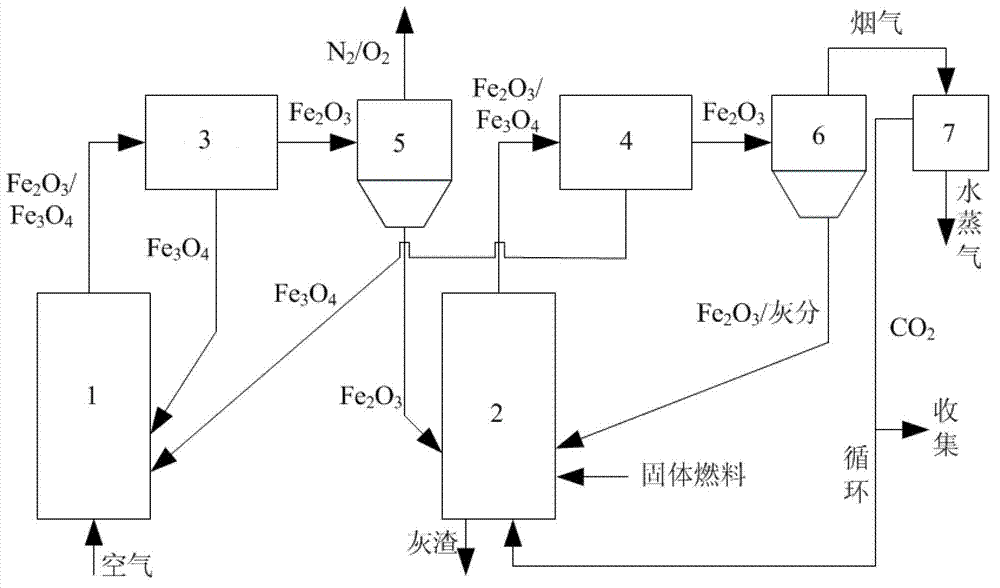

[0029] use figure 1 The structure of the dual electromagnetic control device shown. The solid fuel is lignite, the oxygen carrier is natural iron ore, and the fuel reactor 2 and the air reactor 1 are circulating fluidized bed reactors. Coal and hot Fe 2 o 3 Fully mixed in the fuel reactor 2, and violent gasification reaction and redox reaction occur; part of Fe 2 o 3 is reduced to Fe 3 o 4 Finally, under the action of the second electromagnetic control device 4, with the unreduced Fe 2 o 3 and other solid particles are separated from the fuel reactor 2 into the air reactor 1; Fe 3 o 4 In the air reactor 1 and O 2 reaction and is oxidized to Fe 2 o 3 , and under the action of the first electromagnetic control device 3, with unoxidized Fe 3 o 4 Separation, from the air reactor 1 into the fuel reactor 2, so as to complete the cycle of oxygen carrier. In the 100h experiment, the burnout rate of lignite reached 99%, and the loss rate of iron ore was 3%.

Embodiment 2

[0031] γ-Al 2 o 3 As a support, Fe was prepared by an isometric impregnation method 2 o 3 / γ-Al 2 o 3 As the oxygen carrier, lignite was used as solid fuel, and the chemical looping combustion experiment was carried out by the same process as in Example 1. In the 100h experiment, the burnout rate of lignite reached 99%, Fe 2o 3 / γ-Al 2 o 3 The loss rate of oxygen carrier was 1.5%.

Embodiment 3

[0033] Taking anthracite as solid fuel, the Fe prepared in Example 2 2 o 3 / γ-Al 2 o 3 as an oxygen carrier, and the same process as in Example 2 was used to carry out a chemical looping combustion experiment. In the 100h experiment, the burnout rate of anthracite reached 98.5%, Fe 2 o 3 / γ-Al 2 o 3 The loss rate of oxygen carrier was 1.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com