Chemical power poly-generation energy system and method for recycling CO2

A co-generation energy and poly-generation technology, applied in chemical instruments and methods, chemical industry, sustainable manufacturing/processing, etc., can solve problems such as high energy consumption, low safety factor, difficulty in transportation and storage, and achieve reduction Consumption, reduction of greenhouse gas emissions, and the effect of overcoming a sharp decline in energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

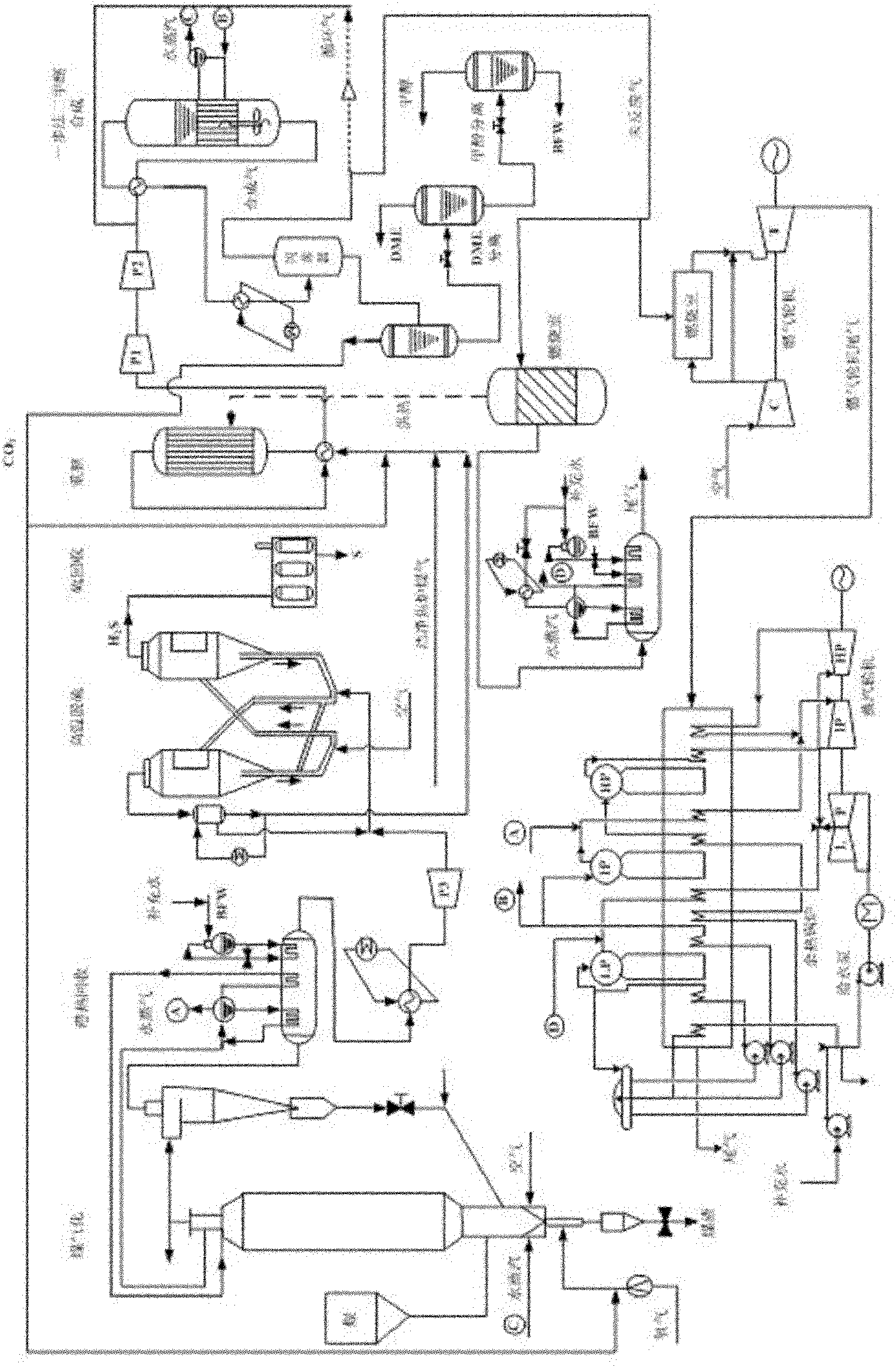

[0020] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in combination with examples and with reference to the accompanying drawings.

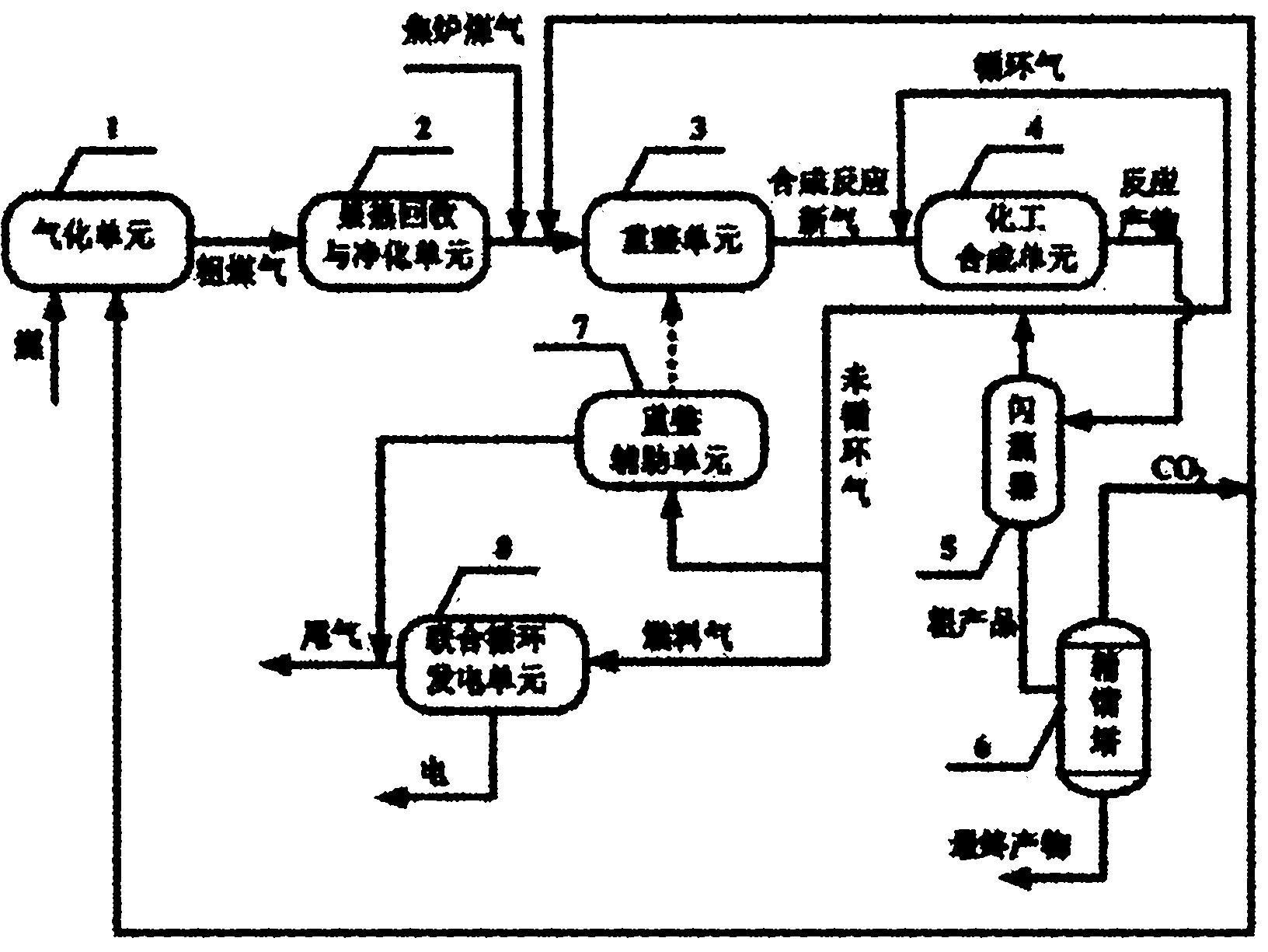

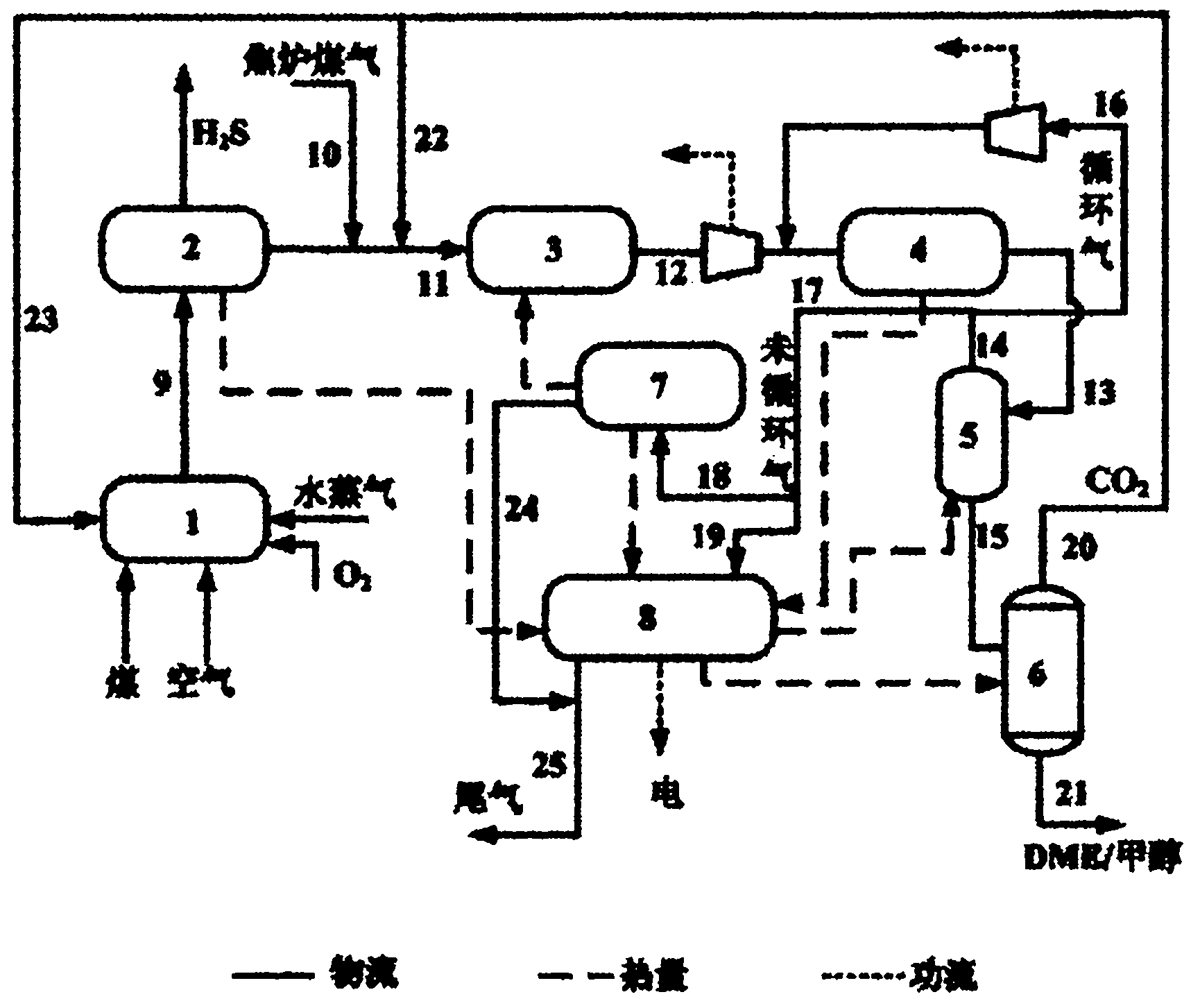

[0021] figure 1 A kind of recyclable CO provided for the present invention 2 Schematic diagram of the chemical power polygeneration energy system structure, the system includes gasification unit 1, synthesis gas sensible heat recovery and purification unit 2, reforming unit 3, chemical synthesis unit 4, flash evaporator 5, rectification tower 6, heavy Whole auxiliary unit 7, combined cycle power generation unit 8. Wherein, the reforming unit 3 includes a first heat exchanger and a reforming reactor. The chemical synthesis unit 4 includes a fresh gas compressor, a circulation compressor, a second heat exchanger and a chemical synthesis reactor.

[0022] Among them, the gasification unit 1 is used to receive a part of recycled CO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com