Coal-based fuel chemical-looping combustion power generation system and method based on supercritical carbon dioxide

A technology of chemical chain combustion and carbon dioxide, which is applied in the direction of machines/engines, gas turbine devices, mechanical equipment, etc., to achieve the effect of reducing costs, reducing emissions, and reducing carbon dioxide emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

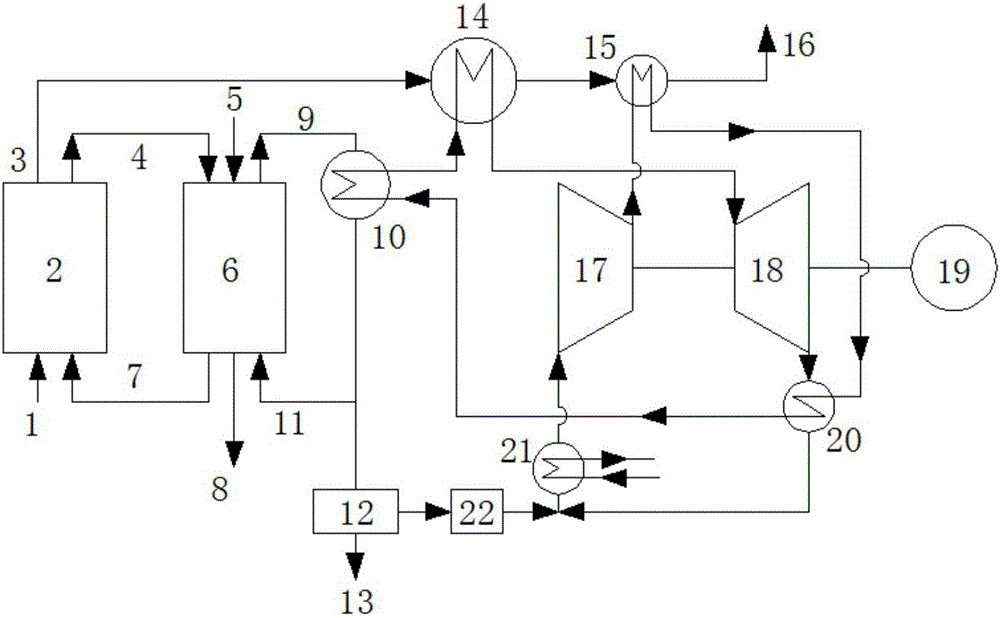

[0040] refer to figure 1 , a kind of coal-based fuel chemical looping combustion power generation system based on supercritical carbon dioxide according to the present invention includes an air reactor 2, a fuel reactor 6 and a carbon dioxide capture device 12 connected in sequence, and is arranged between the fuel reactor 6 and the carbon dioxide The capture device 12 is connected to the low-temperature heat exchanger 10 on the pipeline, which is sequentially connected to the low-temperature medium pipeline of the high-temperature heat exchanger 14 at the low-temperature medium output end of the low-temperature heat exchanger 10, the carbon dioxide turbine 18, and the high-temperature medium pipeline of the regenerator 20 , cooler 21 high temperature medium pipeline, carbon dioxide compresso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com