Electrostatic forming film reflecting surface form design method based on mechanical and electrical field coupling

An electrostatic forming and design method technology, which is applied in computing, electrical digital data processing, special data processing applications, etc., can solve the problems of low film forming precision, only focusing on film shape and surface accuracy, and poor film surface stress uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

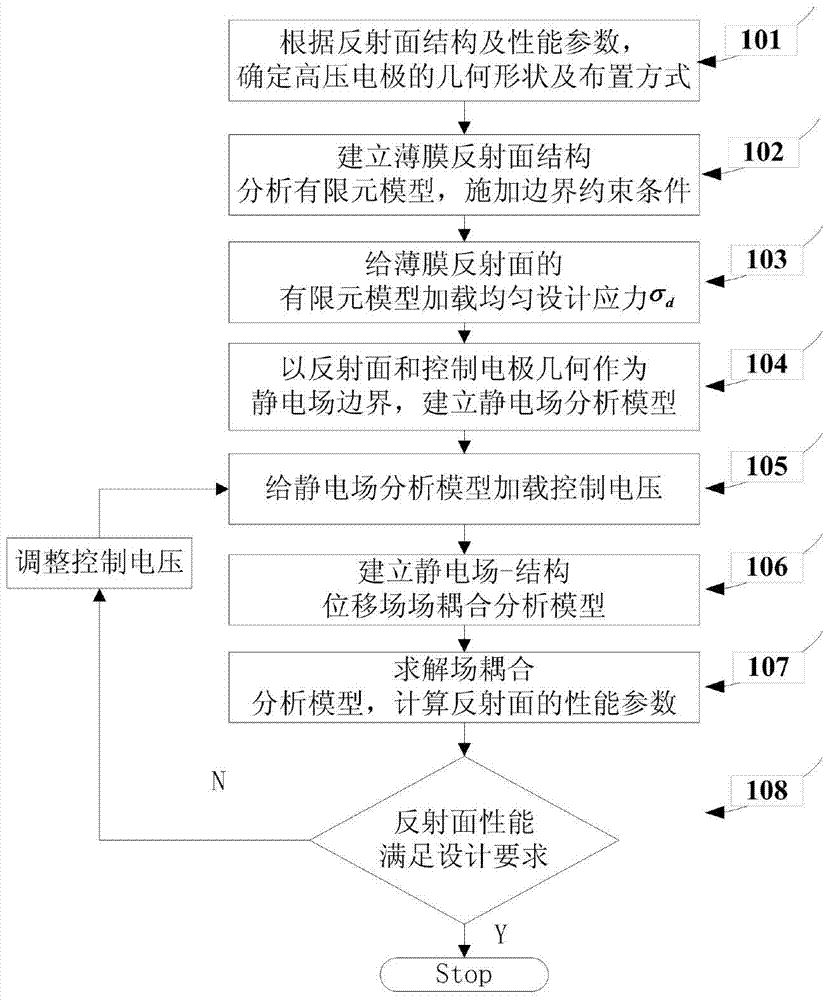

[0047] Such as figure 1 As shown, a method for designing the shape of the reflective surface of an electrostatically formed film based on electromechanical field coupling is characterized in that it at least includes the following steps:

[0048] Step 101: According to the structural parameters of the reflective surface of the electrostatically formed film and the performance requirements of the reflective surface, determine the initial geometry and arrangement of the high-voltage control electrode;

[0049] Step 102: According to the diameter D of the reflective surface of the electrostatically formed film reflective surface a and focal length f a , establish the displacement field analysis model of the membrane structure, and load the boundary constraints;

[0050] Step 103: Apply uniform prestress σ to the structural finite element model of the film reflective surface d ;

[0051] Step 104: Taking the geometry of the film reflector and the high-voltage control electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com