Fragrant environment protection polyvinyl chloride granules

A polyvinyl chloride, aromatic type technology, applied in the field of aromatic environmentally friendly polyvinyl chloride pellets, can solve problems such as taste stimulation, internal organ system harm, soil and water pollution, etc., and achieve pleasant spirits, stable and reliable quality, and reduced pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Aromatic environmentally friendly PVC wire and cable material

[0035] According to any group of ingredients (weight parts) in Example ①~Example ④ in Table 1

[0036] Table I

[0037] component

[0038] polyethylene wax

[0039] Using existing production methods:

[0040] First, the plasticizer, stabilizer, antioxidant, barium stearate and stearic acid are mixed on the three rollers to make pulp, and the pulped mixture is poured into the high-speed mixer, and then PVC resin, polyethylene wax, Highly activated light calcium carbonate filler, deodorant, flavor, flame retardant and colorant, stir at 100 to 120 ° C for 10 to 30 minutes, so that the powder is completely mixed evenly, loose and elastic, and then mixed The uniform material is put into the hopper of the single-screw extruder, and the temperature of each section of the screw is 145-165°C. The material is further completely plasticized, so that the product made of aromatic enviro...

Embodiment 2

[0046] Embodiment 2: Aromatic environment-friendly PVC sole material

[0047] Any group of ingredients (parts by weight) in Examples (1) to (4) in the following list 3

[0048] Table 3

[0049] component

[0050] TOTM plasticizer

[0051] Using existing production methods:

[0052] First, the plasticizer, stabilizer, antioxidant, barium stearate and stearic acid are mixed on the three rollers to make pulp, and the pulped mixture is poured into the high-speed mixer, and then PVC resin, polyethylene wax, Highly activated light calcium carbonate filler, deodorant, flavor and colorant, stir at 100-120°C for 10-30 minutes, so that the powder is completely mixed, loose and elastic, and then add the evenly mixed material into the In the hopper of the single-screw extruder, the temperature of each section of the screw is between 145 and 165°C. The material in the hot-melt state after being plasticized by the extruder is added to the double-roll mill for further p...

Embodiment 3

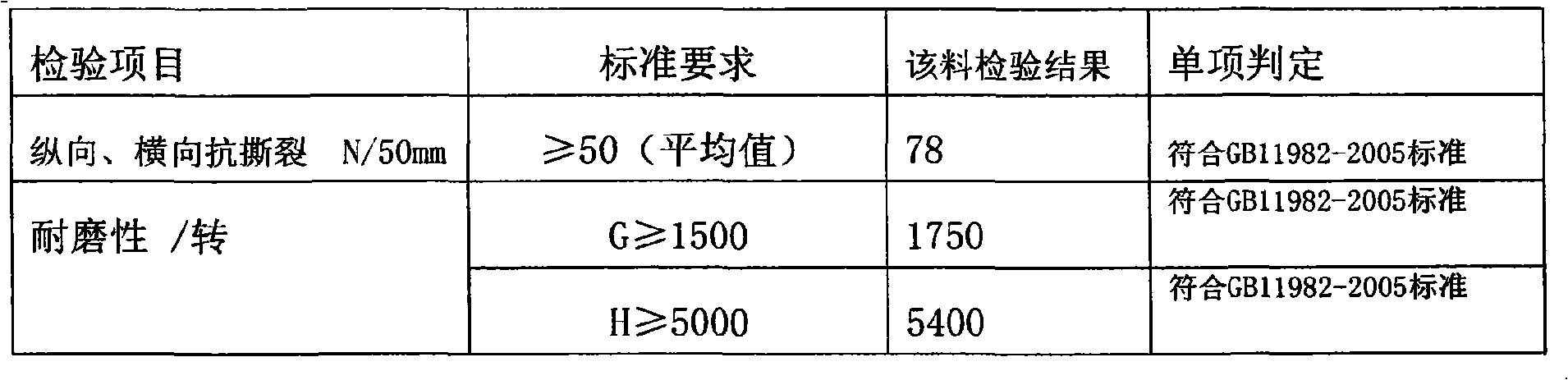

[0057] Example 3: Aromatic environment-friendly PVC floor leather material

[0058] Press any group of ingredients (parts by weight) in Example ~ Example in Table 5

[0059] Table 5

[0060] component

Example

Example

Example

Example

PVC resin

100 copies

100 copies

100 copies

100 copies

DOTP plasticizer

11 servings

15 servings

18 servings

20 servings

TOTM plasticizer

20 servings

32 servings

26 servings

35 servings

Environmentally friendly Ca / Zn heat stabilizer

4 parts

6 servings

5 servings

8 servings

Antioxidant 1010A or 1076

0.2 servings

0.5 servings

0.6 servings

1 serving

0.4 servings

0.6 servings

0.8 servings

1.5 servings

Deodorant SW class

6 servings

10 servings

11 servings

12 servings

plant aromatic essence

6 servings

7 servings

7 servings

7.5 s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com