Method for producing light active calcium carbonate

A technology of activated calcium carbonate and light calcium carbonate, applied in the direction of calcium carbonate/strontium/barium, fibrous fillers, etc., can solve the problems of insignificant improvement in application performance, high power consumption and energy consumption, long process, etc. The effect of suppressing secondary aggregation, good dispersibility, and increasing filling amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] According to the traditional light calcium carbonate production process, the lime is digested and refined by water, and the 3 Add wet calcium stearate (moisture 30%wt) 75Kg (addition is about 2% of finished product calcium carbonate weight) in the refined calcium hydroxide emulsion (analysis calcium hydroxide content is 200g / L), fully stir, pump into the carbonization tower, and then the carbon dioxide (20-35%) gas of passing through purification carries out carbonation reaction to the pH=7-8 of slurry (that is, phenolphthalein does not change red), becomes the calcium carbonate emulsion containing calcium stearate, after dehydration, Drying, crushing and packaging at 100-200°C yields 2.5 tons of finished light active calcium carbonate. The product has been analyzed to reach the first-grade product of HG / T 2567-94. The average particle size is 3.52μm.

Embodiment 2

[0032] According to the traditional light calcium carbonate production process, the lime is digested and refined by water, and the 3 Wet calcium-zinc stearate complex (calcium-zinc ratio is 1, water content 35%wt) 40Kg (addition is about finished product calcium carbonate weight) in the refined calcium hydroxide emulsion (analysis calcium hydroxide content is 200g / L) 1%) and ethanol 30Kg (the addition is about 1.1% of the weight of the finished calcium carbonate), fully stirred evenly, pumped into the carbonization tower, and then the carbonation reaction is carried out to the pH of the slurry by purifying carbon dioxide (20-35%) gas =7-8 (promptly phenolphthalein does not change red), becomes the calcium carbonate emulsion containing calcium stearate, through dehydration, drying at 100-200 ℃, pulverizing and packaging promptly obtains 2.5 tons of finished product light active calcium carbonate. The product has been analyzed to reach the first-grade product of HG / T 2567-94. T...

Embodiment 3

[0034] (1) Preparation of surface treatment agent: add calcium stearate (addition is 2% of calcium carbonate weight) in common stirred tank, then add the ethanol of 1 / 2 calcium stearate amount and appropriate amount of water, fully stir Slurry is made into a slurry with a solid content of about 40%.

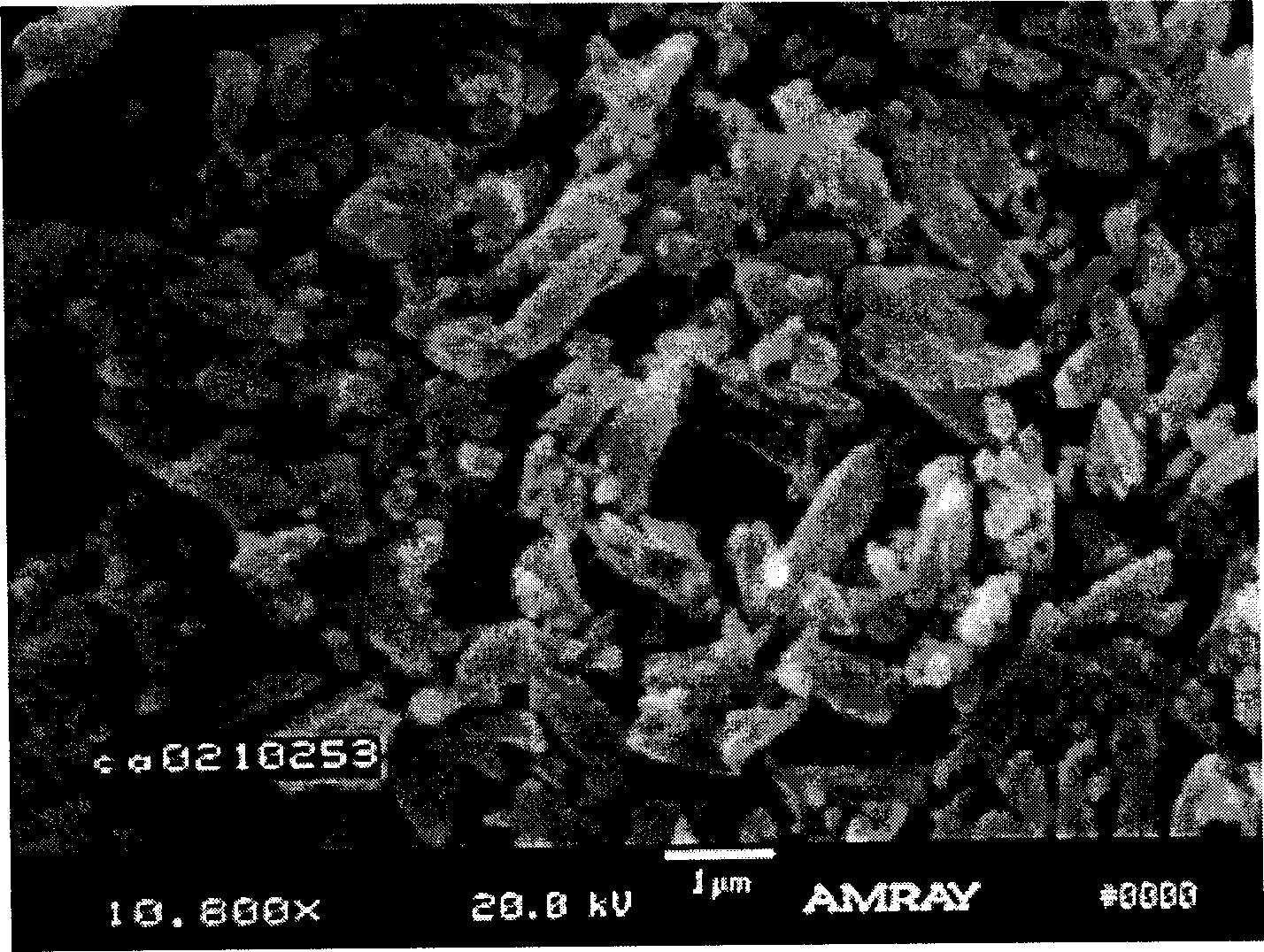

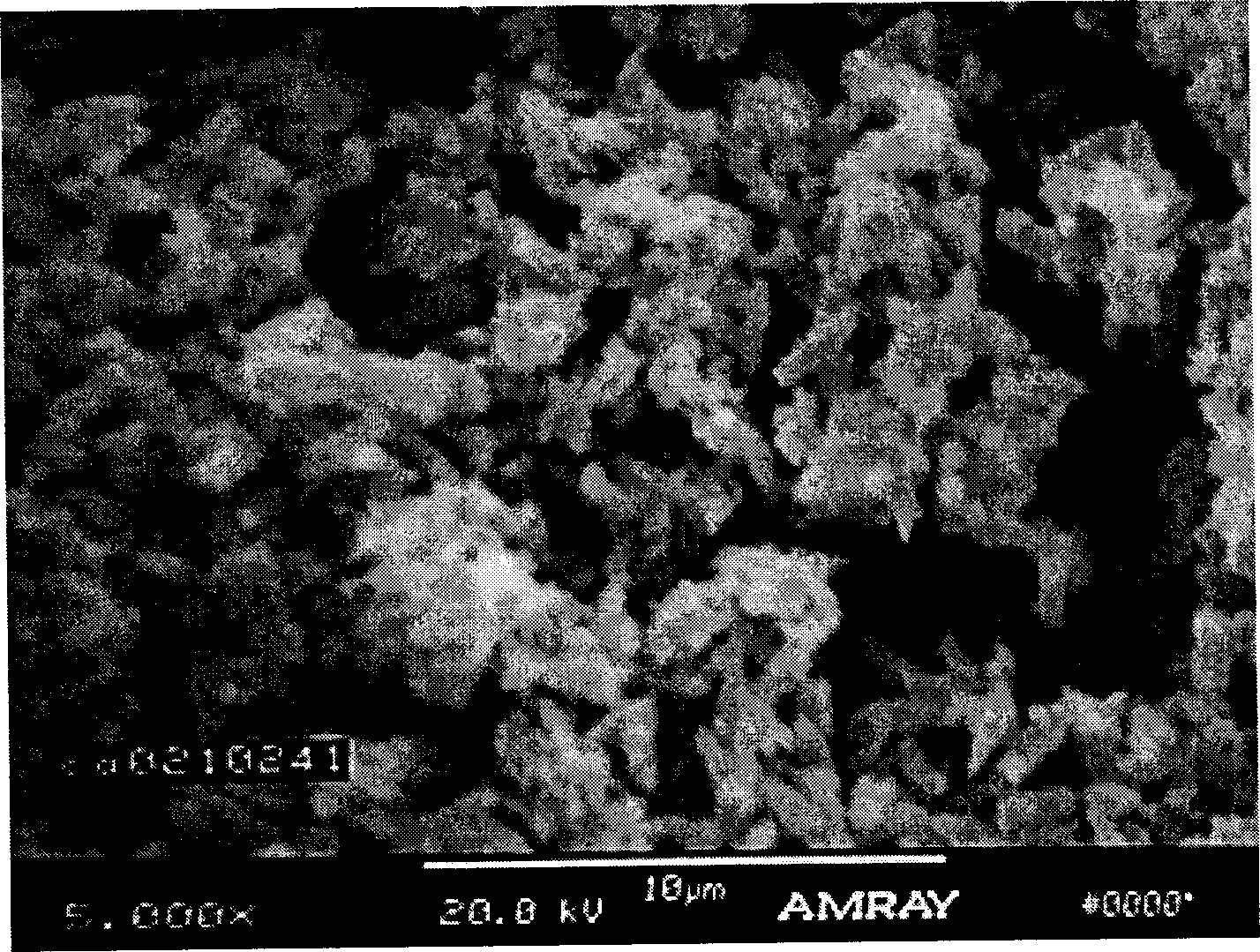

[0035](2) Preparation of ordinary light calcium carbonate: according to the traditional production process of light calcium carbonate, add the upper surface treatment agent into the refined calcium hydroxide emulsion, stir well, and pump carbon dioxide into the carbonization tower under a certain control process Carry out carbonation reaction under certain conditions to form calcium carbonate emulsion, after dehydration, drying, crushing and packaging, it becomes the finished light active calcium carbonate. Product reaches HG / T 2567-94 first grade product through analysis, and product has better dispersibility than embodiment 1, 2, and average particle diameter is 2.85 μ m (see a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com