Preparation method of morphology controllable calcium carbonate based on temperature control

A temperature control, calcium carbonate technology, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc., can solve the problem of increasing production costs, increasing the complexity of the process, and increasing the risk of calcium carbonate production and other problems, to achieve the effect of less restrictions, lower production costs, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Add CaCl 2 Dissolve in water to prepare 0.1mol / L CaCl 2 solution;

[0041] 2) Na 2 CO 3 (or K 2 CO 3) dissolved in water to prepare 0.1mol / L Na 2 CO 3 (or K 2 CO 3 ) solution;

[0042] 3) Place the two solutions in a water bath at 15°C for 10-30 minutes;

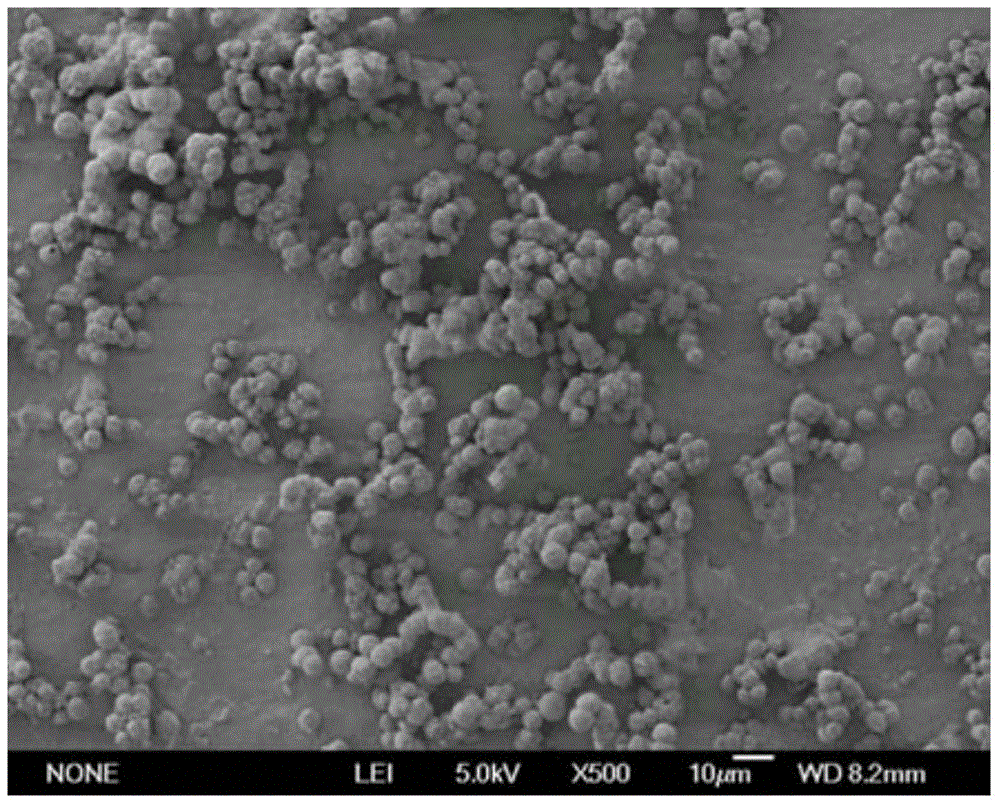

[0043] 4) The two solutions were mixed and stirred for more than 3 minutes without adding any other reagents, and the precipitated product was harvested and dried at room temperature to obtain spherical micron-sized calcium carbonate vaterite crystals (such as figure 1 ).

Embodiment 2

[0045] 1) Add CaCl 2 Dissolve in water to prepare 0.1mol / L CaCl 2 solution;

[0046] 2) Na 2 CO 3 (or K 2 CO 3 ) dissolved in water to prepare 0.1mol / L Na 2 CO 3 (or K 2 CO 3 ) solution;

[0047] 3) Place the two solutions in a water bath at 35°C for 10-30 minutes;

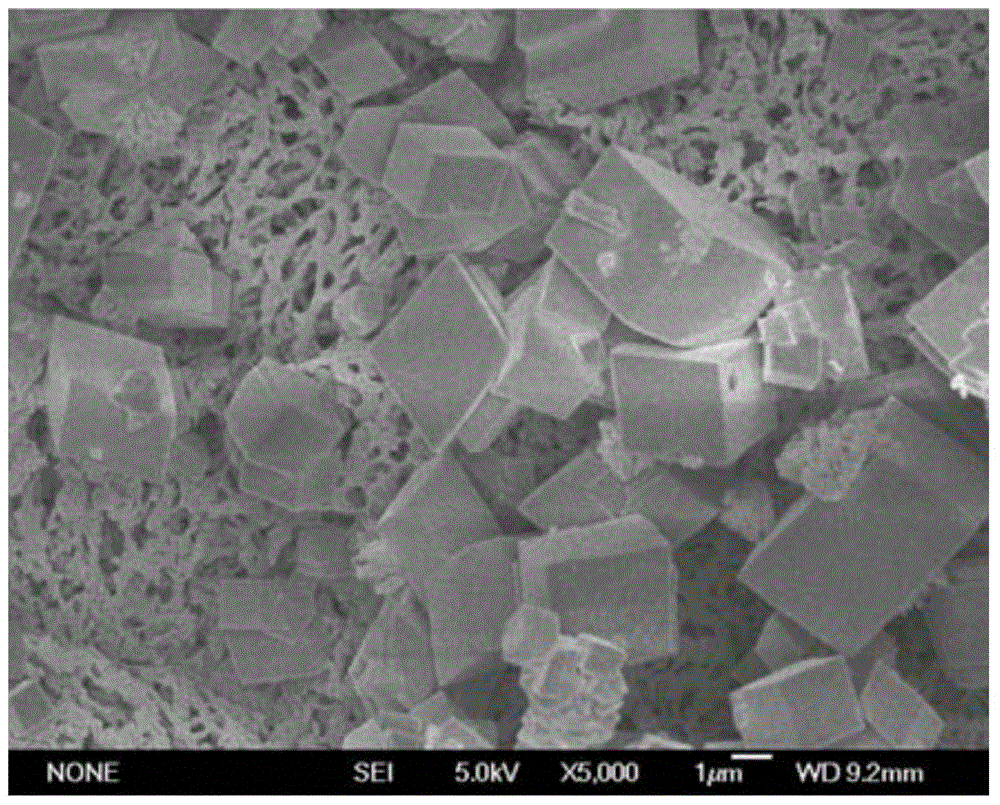

[0048] 4) The two solutions were mixed and stirred for more than 3 minutes without adding any other reagents, and the precipitated product was harvested and dried at room temperature to obtain cubic micron-sized calcium carbonate calcite crystals (such as figure 2 ).

Embodiment 3

[0050] 1) Add CaCl 2 Dissolve in water to prepare 0.1mol / L CaCl 2 solution;

[0051] 2) Na 2 CO 3 (or K 2 CO 3 ) dissolved in water to prepare 0.1mol / L Na 2 CO 3 (or K 2 CO 3 ) solution;

[0052] 3) Place the two solutions in a water bath at 55°C for 10-30 minutes;

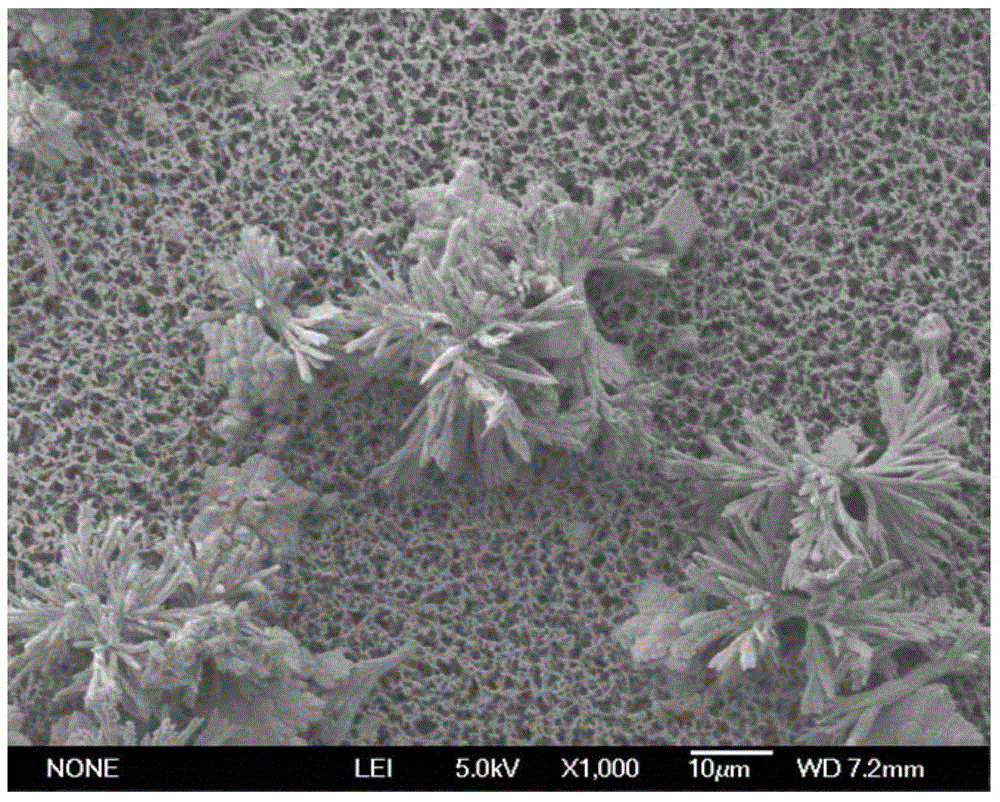

[0053] 4) The two solutions were mixed and stirred for more than 3 minutes without adding any other reagents, and the precipitated product was harvested and dried at room temperature to obtain chrysanthemum-shaped micron-sized calcium carbonate aragonite crystals (such as image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com