Method for preparing calcium carbonate crystal whisker with controllable shape

A calcium carbonate whisker and morphology technology, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, single crystal growth, etc., can solve problems such as difficult control of morphology, achieve good product quality, low energy consumption, The effect of cheap and easy-to-obtain reaction raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

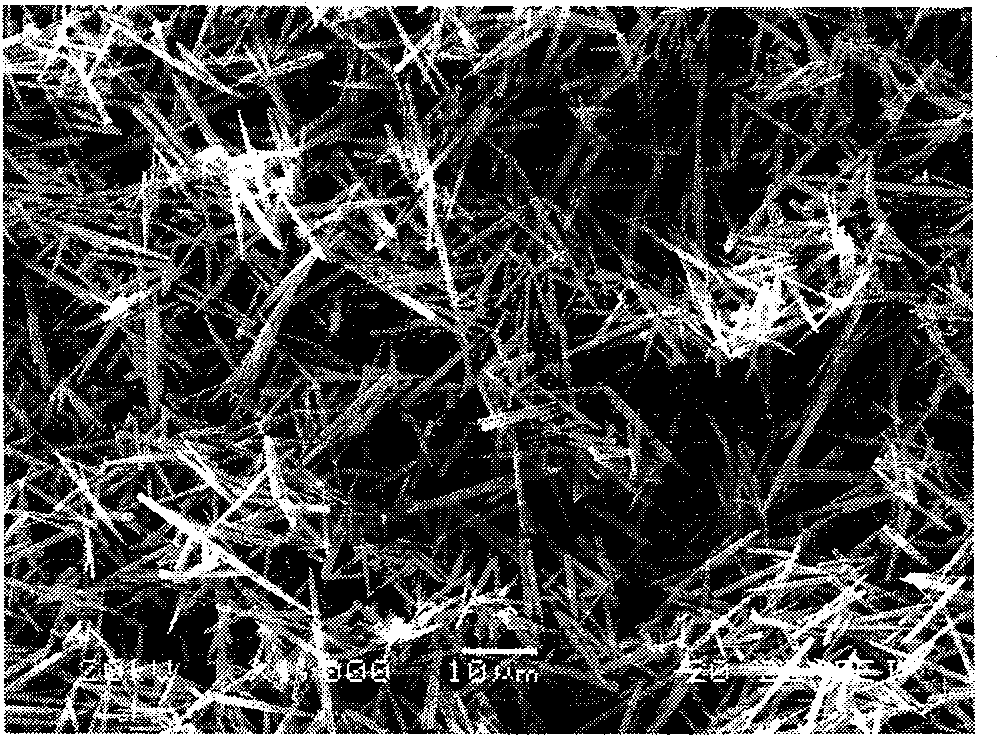

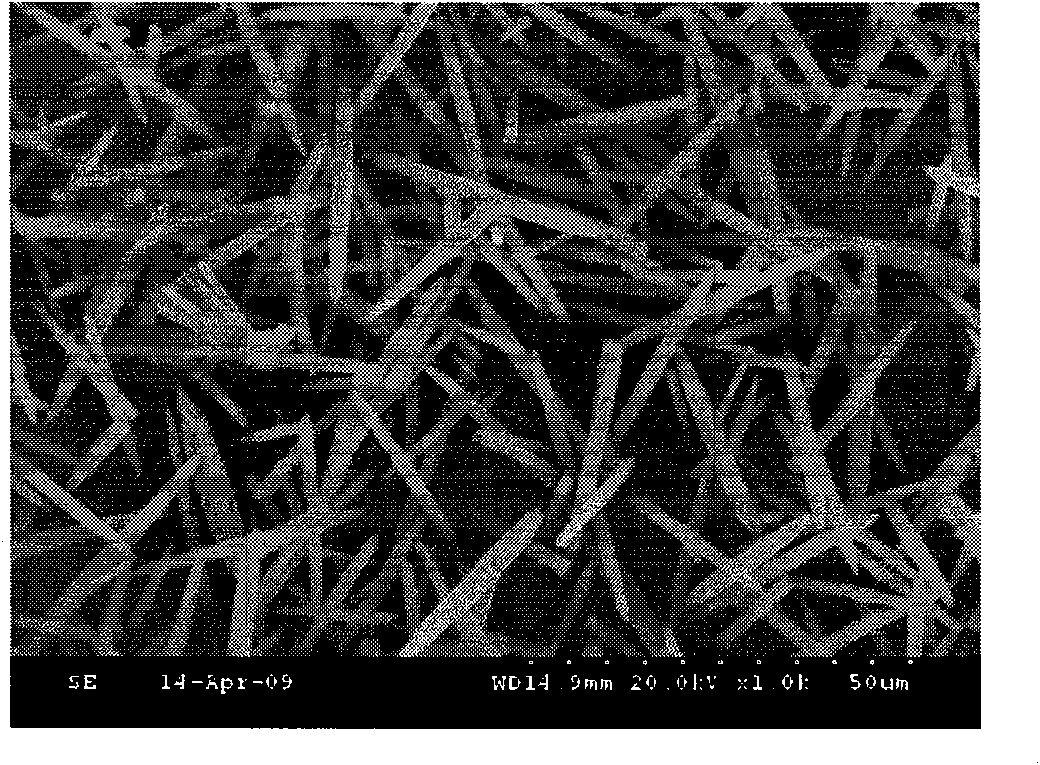

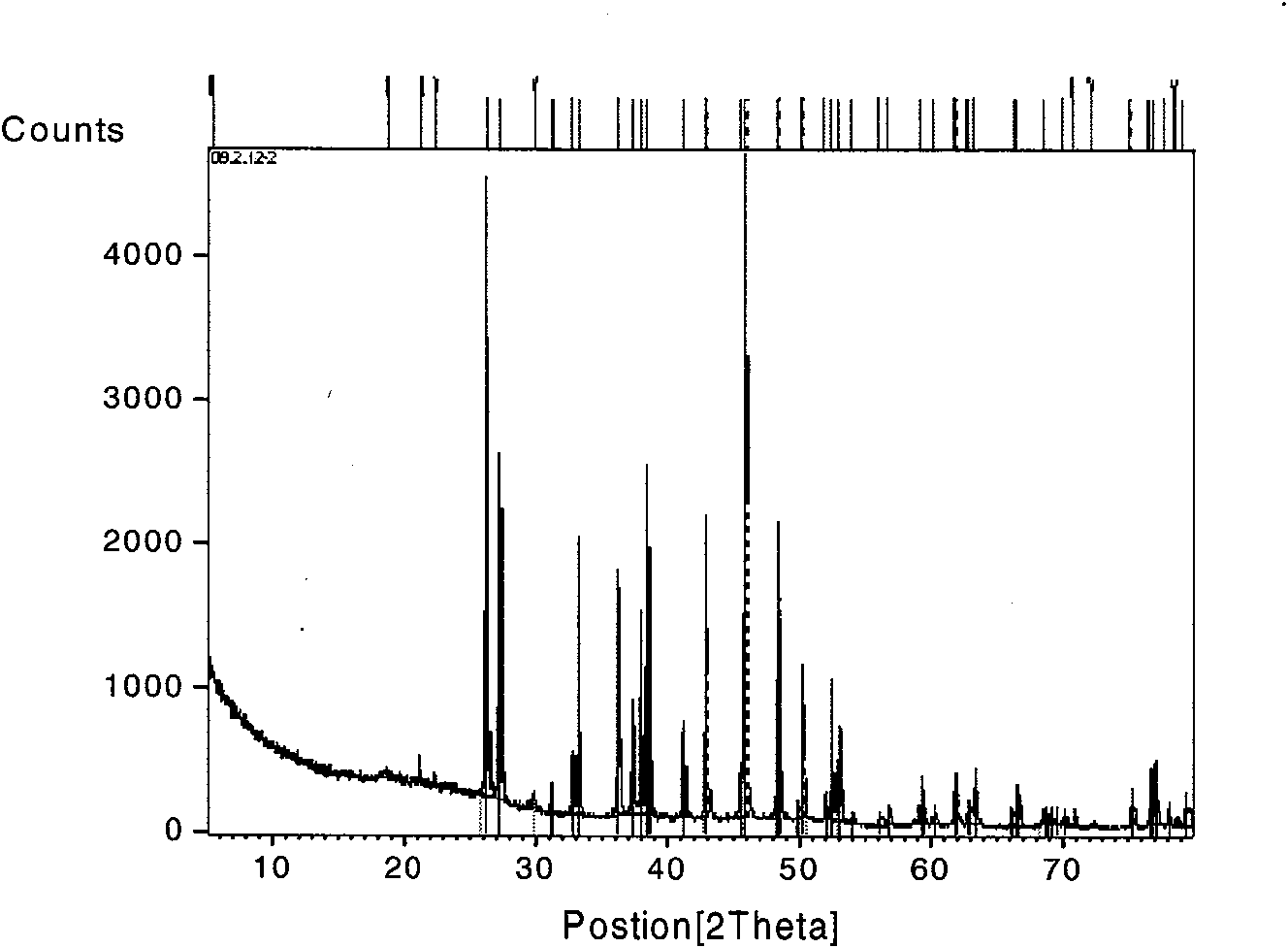

[0020] Embodiment 1, 1. ingredients: add 8L water to dissolve 6kg bischofite, filter for subsequent use; add a small amount of water to digest 618g quicklime for 15hr, pass through a 60 mesh sieve during use, add all in 100L reactor, add water, make the amount of water added Reached 57kg. ②Process conditions: Prepare the slurry to measure the pH value of the solution, control it at about 9, quickly raise the temperature to 80°C, and react for 30 minutes to form MgCl 2 -CaCl 2 -Mg(OH) 2 reaction system. Adjust the carbon dioxide flow rate to 2.0 L / min, measure the pH value of the solution during the reaction, and when the pH value reaches about 7, the reaction ends. ③ Discharge from the discharge port, use a centrifuge to filter the solid-liquid separation, collect the mother liquor, store it for later use, the solid phase is calcium carbonate whiskers, then wash with water, and wash while centrifuging to obtain a calcium carbonate whisker filter cake. ④The whisker filter c...

Embodiment 2

[0021] Embodiment 2, ① ingredients: 60kg experiment one mother liquor; 690g unslaked lime is digested with a small amount of water for 15hr, passed through a 60-mesh sieve, all added to a 100L reactor, and started to stir. ②Process conditions: Prepare the slurry to measure the pH value of the solution, control it at about 9, quickly raise the temperature to 80°C, and react for 30 minutes to form MgCl 2 -CaCl 2 -Mg(OH) 2 reaction system. Adjust the flow rate of carbon dioxide to 2.5 L / min, and measure the pH value of the solution during the reaction. When the pH value reaches about 7, the reaction ends. ③ Discharge from the discharge port, use a centrifuge to filter the solid-liquid separation, collect the mother liquor, and store it for later use; the solid phase is calcium carbonate whiskers, wash with water, and wash while centrifuging to obtain calcium carbonate whisker filter cakes. ④The whisker filter cake was dried in an oven at 90°C for 6 hours. Obtained calcium ca...

Embodiment 3

[0022] Embodiment 3, 1. Ingredients: 51.5kg of experiment two mother liquor; 775g of quicklime was digested with a small amount of water for 15hr, and passed through a 60-mesh sieve during use; 10kg of water was added; all were added in a 100L reactor, and started stirring. ②Process conditions: Prepare the slurry to measure the pH value of the solution, control it at about 9, quickly raise the temperature to 80°C, and react for 30 minutes to form MgCl 2 -CaCl 2 -Mg(OH) 2 reaction system. Adjust the flow rate of carbon dioxide to 2.5 L / min, and measure the pH value of the solution during the reaction. When the pH value reaches about 7, the reaction ends. ③ Discharge from the discharge port, use a centrifuge to filter the solid-liquid separation, collect the mother liquor, and store it for later use; the solid phase is calcium carbonate whiskers, wash with water, and wash while centrifuging to obtain calcium carbonate whisker filter cakes. ④The whisker filter cake was dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com