Process for preparing light magnesium oxide and calcium carbonate powder by utilizing dolomite acid method

A technology of light magnesium oxide and calcium carbonate powder, which is applied in the direction of magnesium oxide, calcium carbonate/strontium/barium, etc., can solve the problems of environmental pollution, high energy consumption, and large waste residue discharge, and achieve reasonable process design and low energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

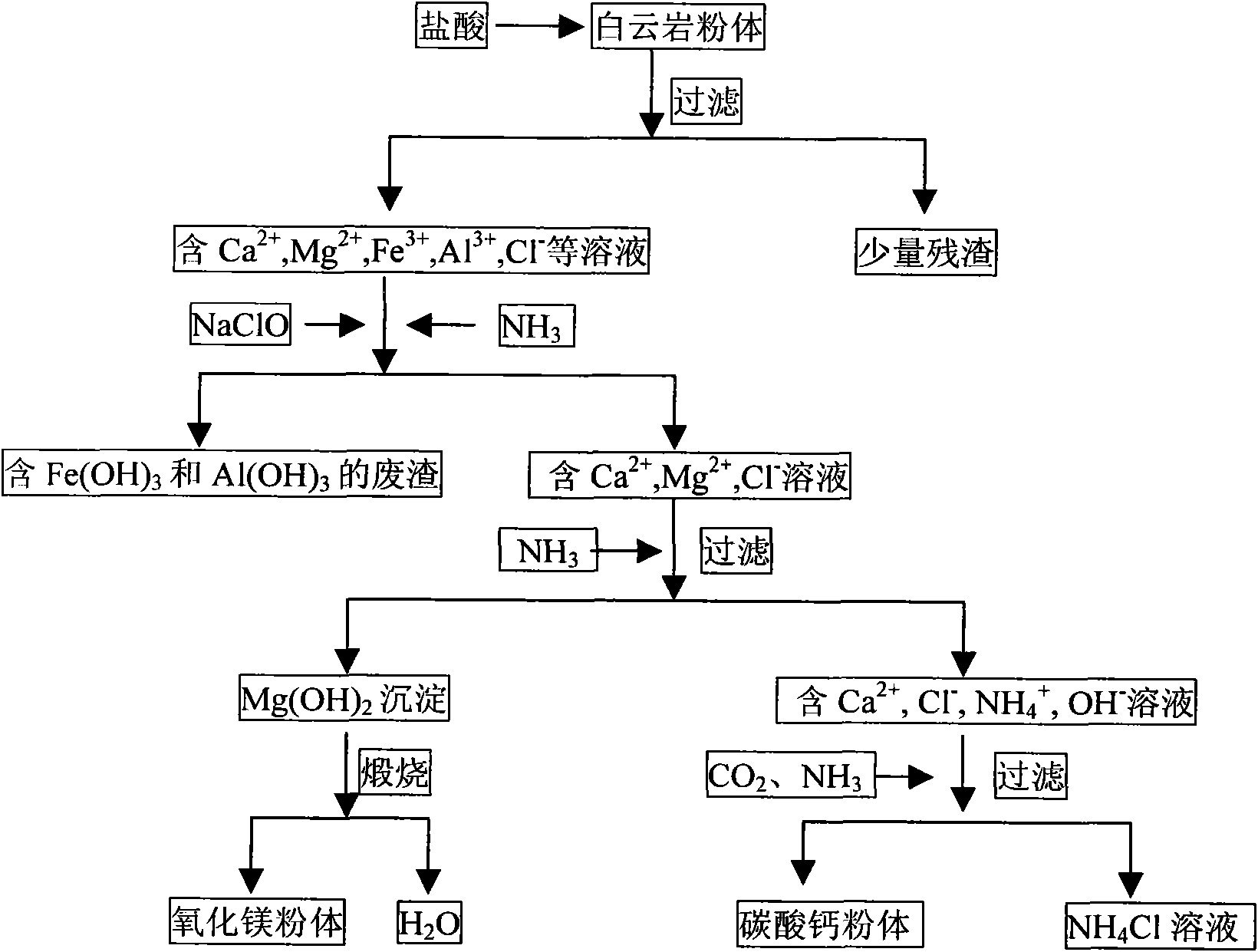

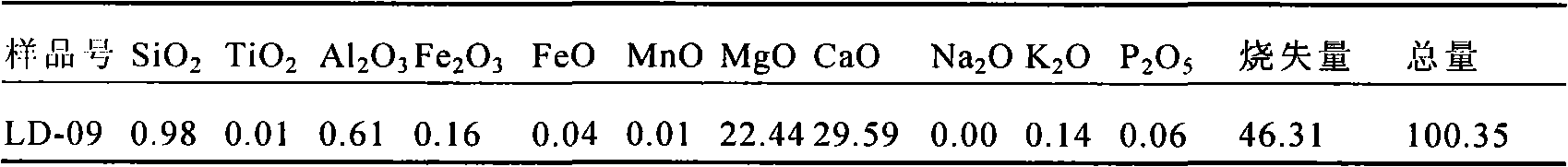

[0023] The process for preparing light magnesium oxide and calcium carbonate powder by dolomite acid method of the present invention uses dolomite as raw material, and the production process includes raw material pretreatment, dolomite acid dissolution, impurity removal, ammonia precipitation of magnesium, and magnesium hydroxide calcination and calcium carbonate preparation process.

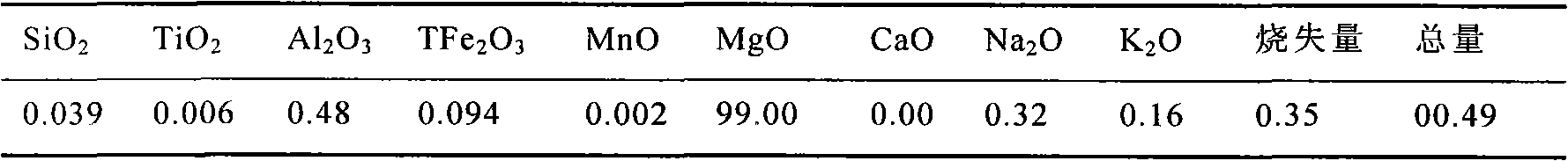

[0024] After the dolomite is crushed and ball-milled, it is added into a hydrochloric acid solution with a mass fraction of 25% to 30% to dissolve. Take the supernatant, add a small amount of NaClO solution, then pass through ammonia gas to adjust the pH value between 5 and 7, and filter to obtain pure MgCl 2 , CaCl 2 solution. Then feed ammonia gas into it, react for 1 to 3 hours, filter, filter cake, wash and dry to obtain magnesium hydroxide precipitate; the precipitate is calcined to obtain light magnesium oxide powder product; the filtrate is passed through ammonia gas, carbonized, filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com