Production of high-purity spherical nano-calcium carbonate

A calcium carbonate and nanotechnology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of high performance requirements of reaction equipment, uneven particle size distribution, high energy consumption in the reaction process, shorten the reaction time, optimize the production process, save input effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

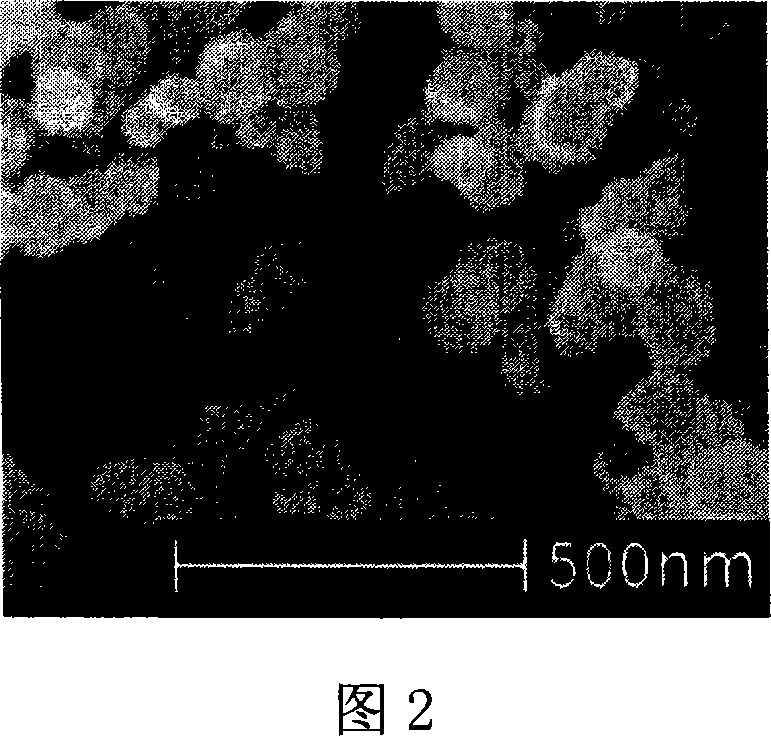

[0020] Embodiment 1: the dissolving temperature is 90 DEG C, under the condition of continuous stirring, calcium chloride is dissolved in deionized water, and the impurity removal agent of calcium chloride weight 3% is added in the solution simultaneously, and this impurity removal agent is hydroxide A mixture of calcium and polyacrylamide mixed at a ratio of 4:1, then filter out impurities, add water to prepare a 0.4mol / L calcium chloride solution; dissolve sodium hydroxide in deionized water to prepare a 5.0mol / L hydroxide Sodium solution, then lowered to room temperature, under the condition of continuous stirring, let it slowly flow into the calcium chloride solution for reaction, and control the reaction temperature at 30°C to obtain calcium hydroxide slurry; pump the above calcium hydroxide slurry into Into the carbonization reactor, feed pure carbon dioxide for carbonization, and control the reaction temperature not to exceed 30°C, detect the pH value of the reaction sol...

Embodiment 2

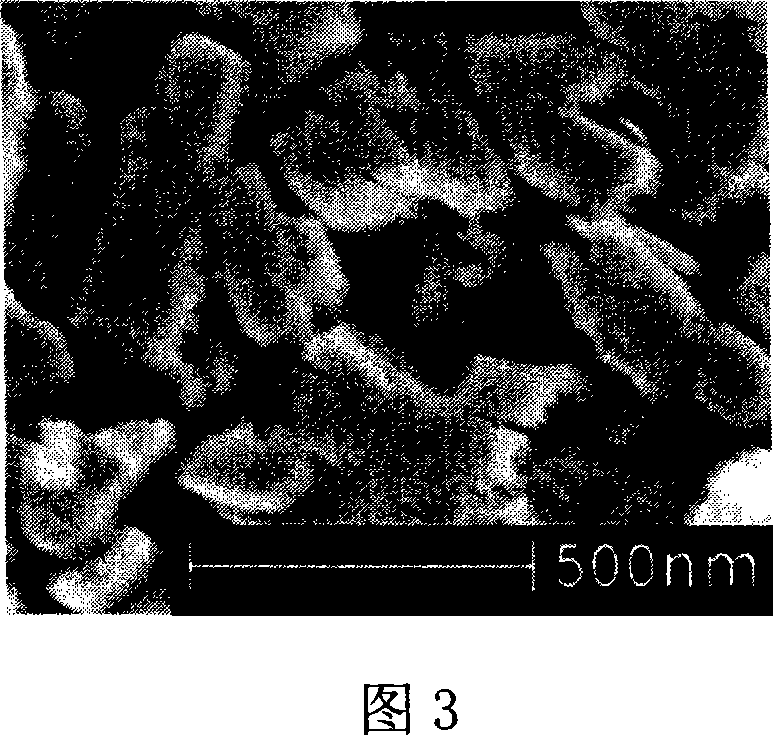

[0022] Embodiment 2: the dissolving temperature is 95 ℃, under the condition of continuous stirring, calcium chloride is dissolved in deionized water, and the impurity removal agent of calcium chloride weight 4% is added in the solution simultaneously, and this impurity removal agent is hydroxide A mixture of calcium and polyacrylamide mixed at a ratio of 5:1, then filter out impurities, add water to prepare a 0.2mol / L calcium chloride solution; dissolve sodium hydroxide in deionized water to prepare a 3.5mol / L hydroxide Sodium solution, then lowered to room temperature, under the condition of continuous stirring, let it slowly flow into the calcium chloride solution for reaction, and control the reaction temperature at 25°C to obtain calcium hydroxide slurry; pump the above calcium hydroxide slurry into Into the carbonization reactor, feed pure carbon dioxide for carbonization, and control the reaction temperature to 25°C, and check the pH value of the reaction solution. When ...

Embodiment 3

[0024] Embodiment 3: the dissolving temperature is 100 ℃, under the condition of continuous stirring, calcium chloride is dissolved in deionized water, and the impurity removal agent of calcium chloride weight 5% is added in the solution simultaneously, and this impurity removal agent is hydroxide The mixture of calcium and polyacrylamide mixed in a ratio of 3:1 is prepared by adding water to prepare a 0.3mol / L calcium chloride solution; dissolving sodium hydroxide in deionized water to prepare a 2.5mol / L sodium hydroxide solution, and then To room temperature, under the condition of continuous stirring, let it slowly flow into the calcium chloride solution for reaction, and control the reaction temperature at 20°C to obtain calcium hydroxide slurry; pump the above calcium hydroxide slurry into the carbonization reactor , feed pure carbon dioxide for carbonization, and control the reaction temperature to 20°C, detect the pH value of the reaction solution, and when the pH value ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com