Process for producing high-purity electronic grade strontium carbonate

An electronic-grade strontium carbonate technology, which is applied in the field of preparation of high-purity electronic-grade strontium carbonate, can solve the problems of high performance requirements of reaction equipment, uneven particle size distribution, and high energy consumption in the reaction process, so as to reduce energy consumption and protect the environment Pollution, simple structure, and the effect of optimizing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

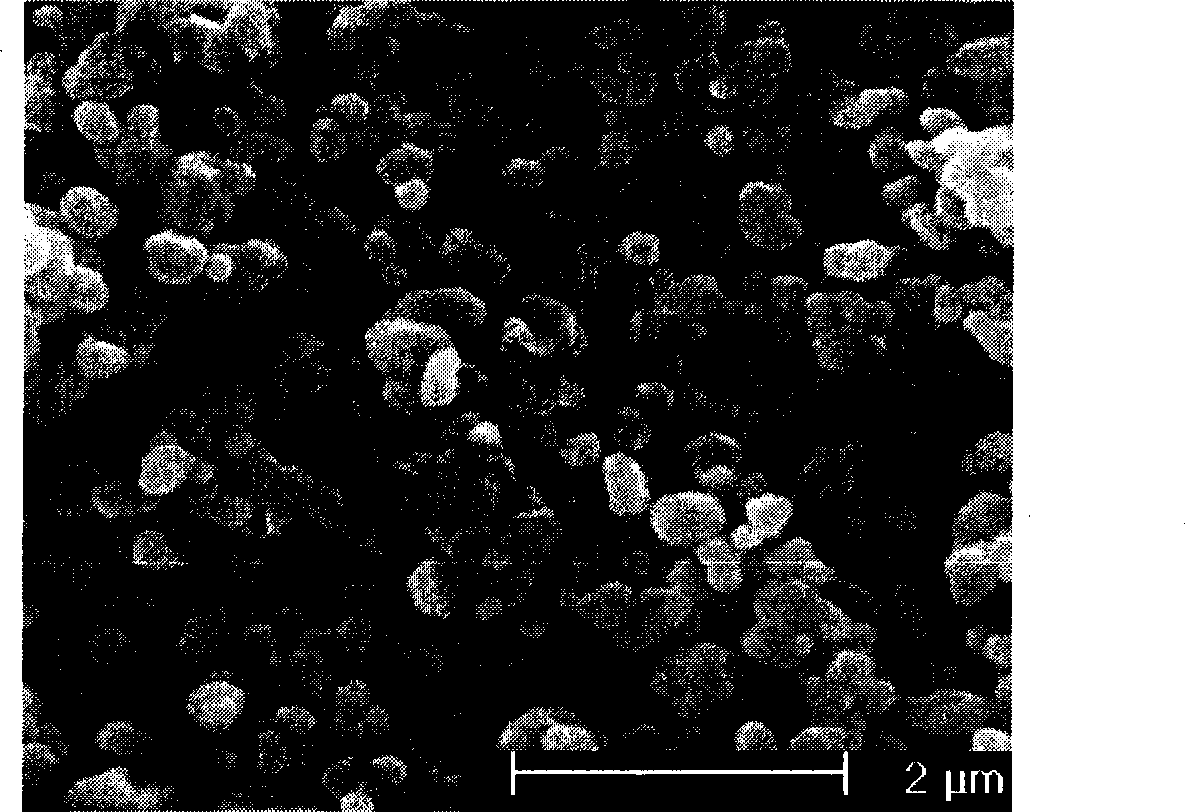

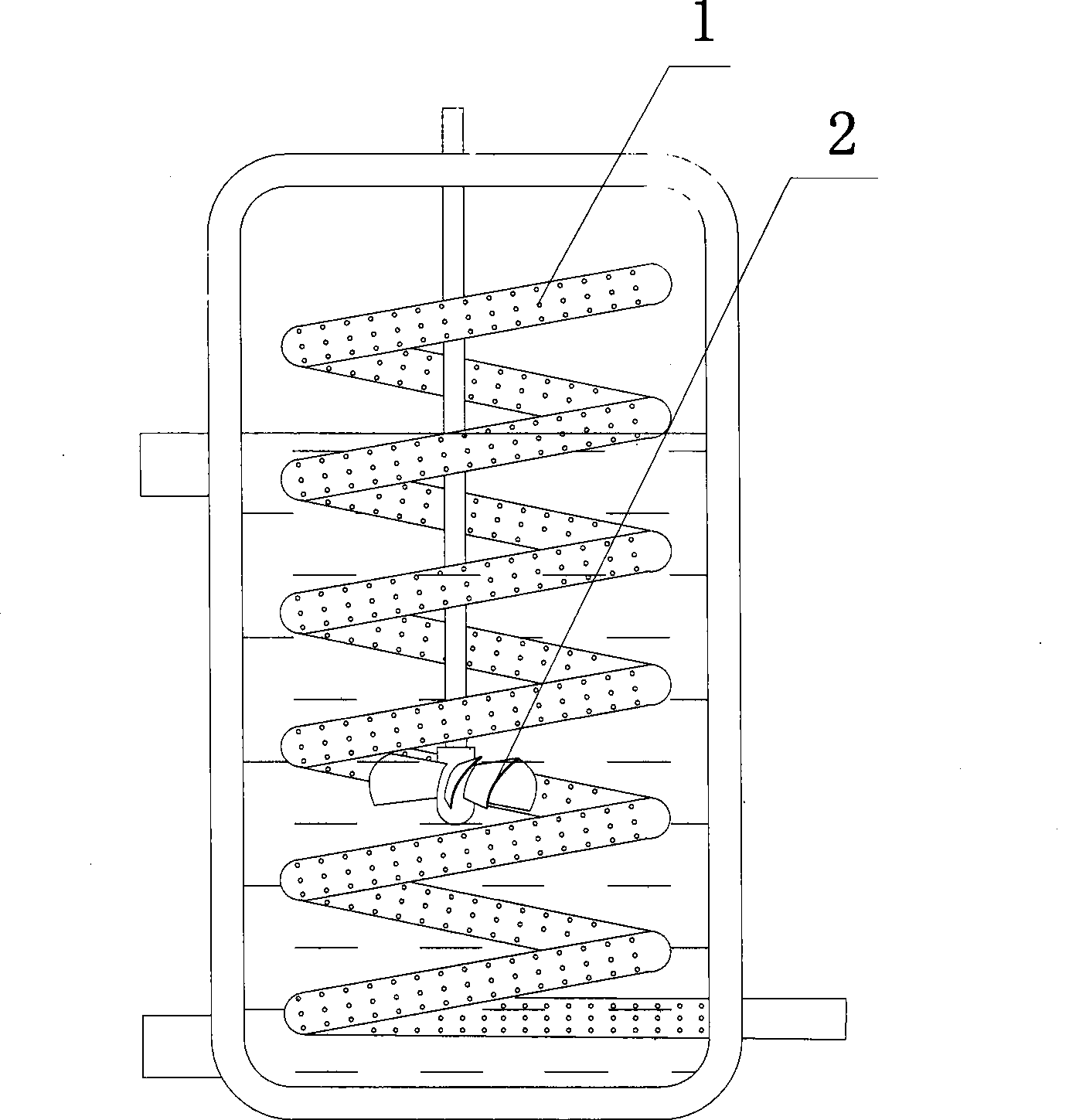

Embodiment 1

[0019] Embodiment 1: the dissolving temperature is 90 DEG C, under the condition of continuous stirring, strontium chloride is dissolved in deionized water, and the impurity removing agent of strontium chloride weight 3% is added in the solution simultaneously, and this impurity removing agent is hydroxide A mixture of strontium and microbial flocculant MBFA9 in a ratio of 2:1, then filter out impurities, add water to prepare a 0.4mol / L strontium chloride solution; dissolve sodium hydroxide in deionized water to prepare a 5.0mol / L hydrogen Sodium oxide solution, then lowered to room temperature, under the condition of continuous stirring, let it slowly flow into the strontium chloride solution for reaction, and control the reaction temperature to be 80°C to obtain strontium hydroxide solution; pump the above strontium hydroxide solution into the carbonization reactor (e.g. figure 2 As shown, the shell of the carbonization reactor is provided with a helical microporous aeratio...

Embodiment 2

[0021] Embodiment 2: the dissolving temperature is 95 DEG C, under the condition of continuous stirring, strontium chloride is dissolved in deionized water, and simultaneously in solution, add the impurity removal agent of strontium chloride weight 4%, this impurity removal agent is hydroxide A mixture of strontium and microbial flocculant MBFA9 in a ratio of 3:1, then filter out impurities, add water to prepare a 0.2mol / L strontium chloride solution; dissolve sodium hydroxide in deionized water to prepare a 3.5mol / L hydrogen Sodium oxide solution, then lowered to room temperature, under the condition of continuous stirring, let it slowly flow into the strontium chloride solution to react, and control the reaction temperature to be 70°C to obtain strontium hydroxide solution; pump the above strontium hydroxide solution into the carbonization reactor, feed pure carbon dioxide for carbonization, and control the reaction temperature to 70 ° C, and detect the pH value of the reacti...

Embodiment 3

[0022] Embodiment 3: the dissolving temperature is 100 ℃, under the condition of continuous stirring, strontium chloride is dissolved in deionized water, and the impurity removing agent of strontium chloride weight 5% is added in the solution simultaneously, and this impurity removing agent is hydroxide A mixture of strontium and microbial flocculant MBFA9 in a ratio of 2.5:1, then filter out impurities, add water to prepare a 0.3mol / L strontium chloride solution; dissolve sodium hydroxide in deionized water to prepare a 2.5mol / L hydrogen Sodium oxide solution, then lowered to room temperature, under the condition of continuous stirring, let it slowly flow into the strontium chloride solution to react, and control the reaction temperature to be 75°C to obtain strontium hydroxide solution; pump the above strontium hydroxide solution into the carbonization reactor, feed pure carbon dioxide for carbonization, and control the reaction temperature to 75°C, detect the pH value of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com