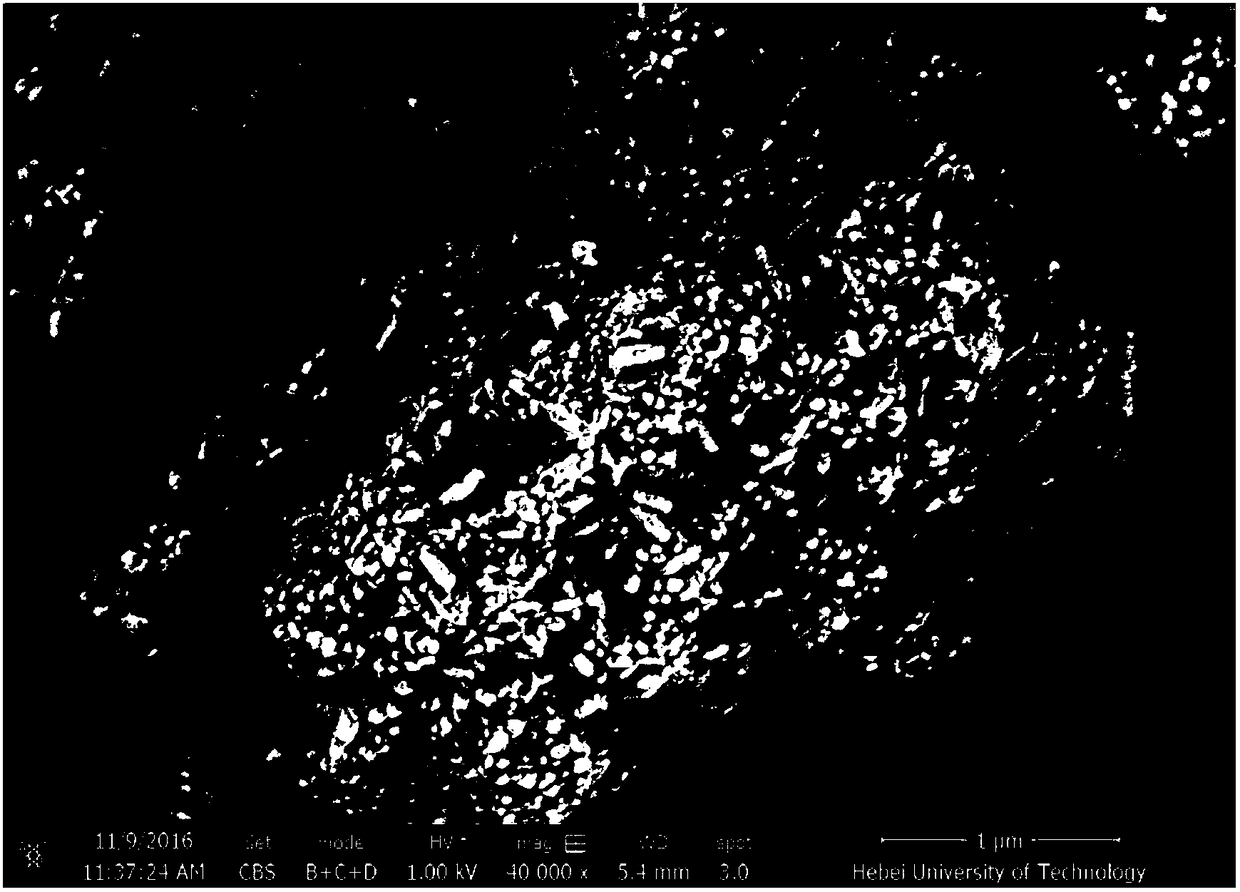

Preparation method for rice-grain-shaped light calcium carbonate

A technology of light calcium carbonate and calcium carbonate, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, nanotechnology, etc. , can not play the application effect and other problems, to achieve the effect of low cost, good dispersion, good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of rice granular light calcium carbonate, comprising the following steps,

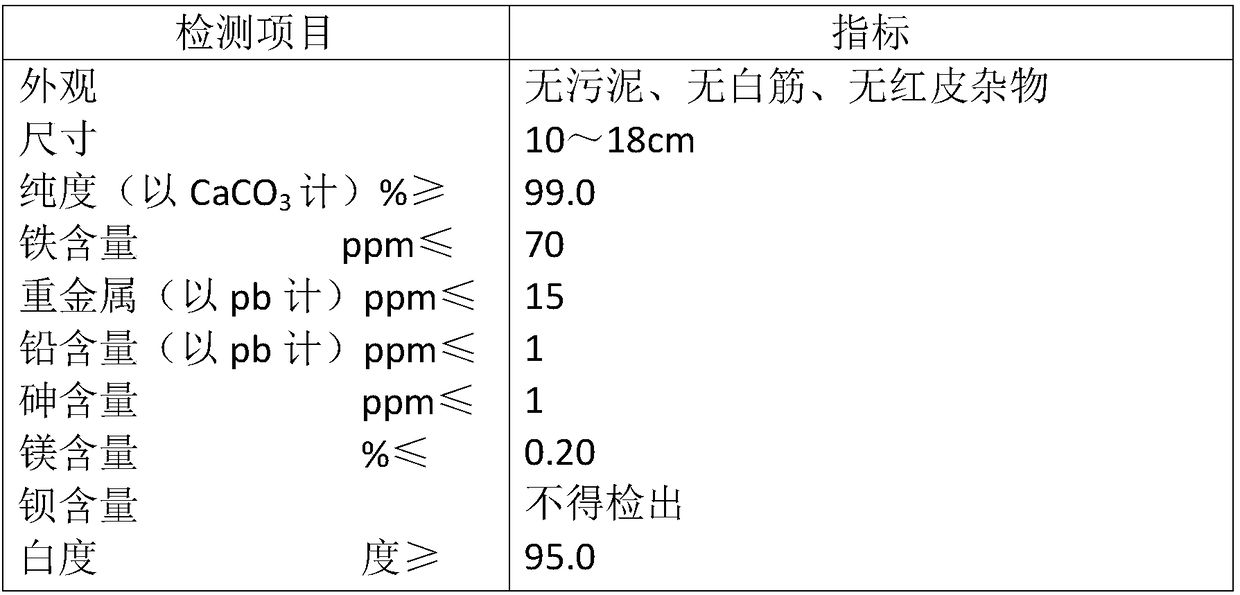

[0037] Step 1, limestone is taken and calcined with natural gas to obtain calcium oxide;

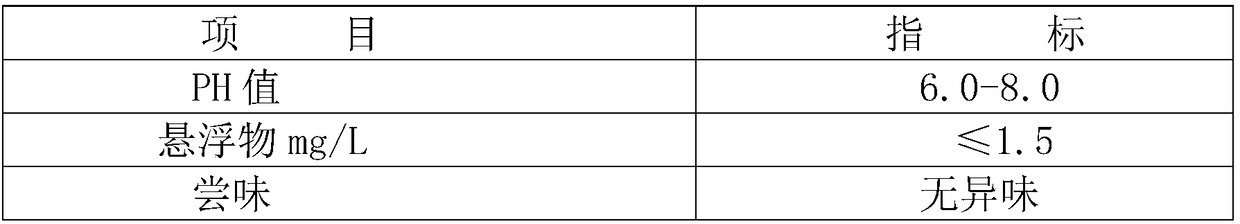

[0038] Step 2. Mix calcium oxide and digested water according to the mass ratio of 1:5. After mixing, put it into a digestion kettle for digestion reaction. After the digestion reaction is completed, sieve it through a 320-mesh vibrating sieve, and remove impurities to obtain Calcium hydroxide essence, the calcium hydroxide essence is aged in the aging tank for 50 hours;

[0039] Step 3. Adjust the concentration of the aged calcium hydroxide fine slurry to 1.2mol / L, add a crystal form control agent of 0.4% by weight of limestone on a dry basis, and adjust the temperature to 30°C; the crystal form control agent includes ethylenediamine , a mixture of diethylenetriamine and triethylenetetramine, ethylenediamine, diethylenetriamine and triethylenetetramine are mixed in a ratio of 2:2:1. ...

Embodiment 2

[0053] A preparation method of rice granular light calcium carbonate, comprising the following steps,

[0054] Step 1, limestone is taken and calcined with natural gas to obtain calcium oxide;

[0055] Step 2. Mix calcium oxide and digested water according to the mass ratio of 1:5. After mixing, put it into a digestion kettle for digestion reaction. After the digestion reaction is completed, sieve it through a 320-mesh vibrating sieve, and remove impurities to obtain Calcium hydroxide essence, the calcium hydroxide essence is aged in the aging tank for 45 hours;

[0056] Step 3. Adjust the concentration of the aged calcium hydroxide fine slurry to 1.5mol / L, add a crystal form control agent of 0.5% by weight of limestone on a dry basis, and adjust the temperature to 33° C.; the crystal form control agent includes ethylenediamine , a mixture of diethylenetriamine and triethylenetetramine, ethylenediamine, diethylenetriamine and triethylenetetramine are mixed in a ratio of 1:1:1...

Embodiment 3

[0063] A preparation method of rice granular light calcium carbonate, comprising the following steps,

[0064] Step 1, limestone is taken and calcined with natural gas to obtain calcium oxide;

[0065] Step 2. Mix calcium oxide and digested water according to the mass ratio of 1:5. After mixing, put it into a digestion kettle for digestion reaction. After the digestion reaction is completed, sieve it through a 320-mesh vibrating sieve, and remove impurities to obtain Calcium hydroxide essence, the calcium hydroxide essence is aged in the aging tank for 60 hours;

[0066] Step 3. Adjust the concentration of the aged calcium hydroxide fine slurry to 1mol / L, add a crystal form control agent of 0.3% by weight of limestone on a dry basis, and adjust the temperature to 32° C.; the crystal form control agent includes ethylenediamine, A mixture of diethylenetriamine and triethylenetetramine, ethylenediamine, diethylenetriamine and triethylenetetramine are mixed in a ratio of 1:3:2. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com