Rotary fire grate

A technology of rotating grate and rotating shaft, applied in the direction of rotary grate, grate, shaking grate, etc., can solve the problems of reduced biomass fuel gasification efficiency, worn equipment, low cleaning efficiency, etc., and achieves compression of the overall shape Size, saving combustion space, increasing temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with embodiment, but is not limited to the content on the description.

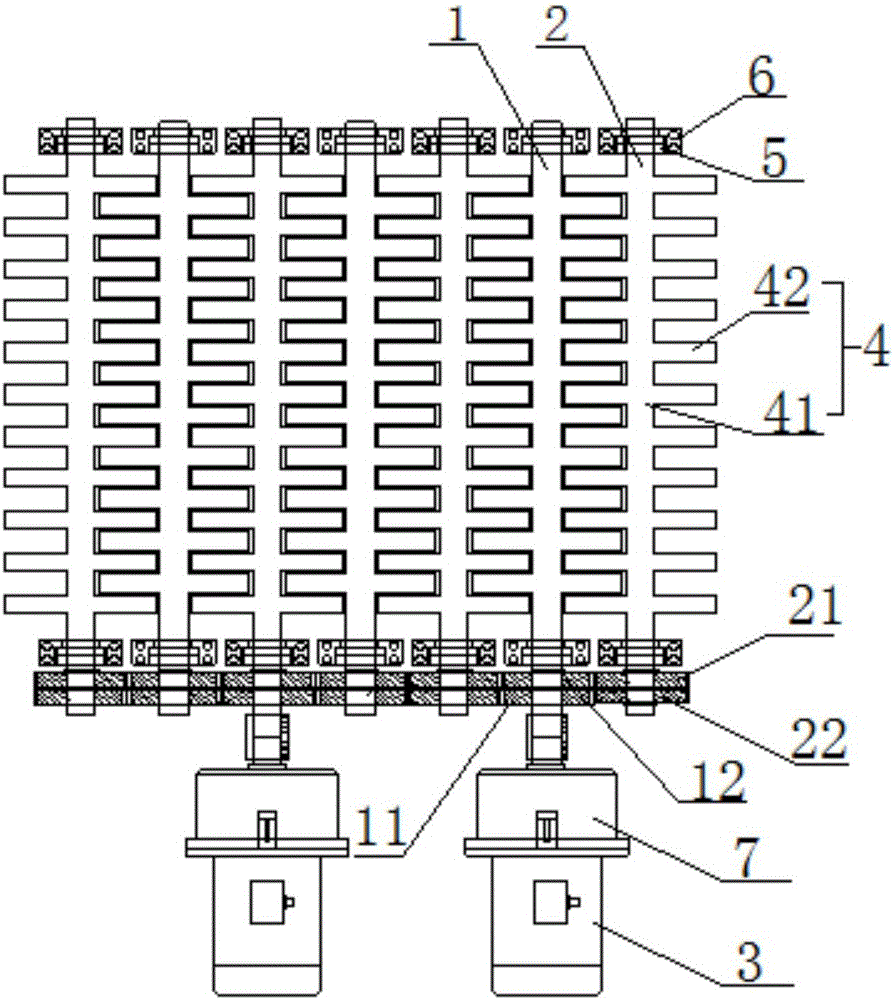

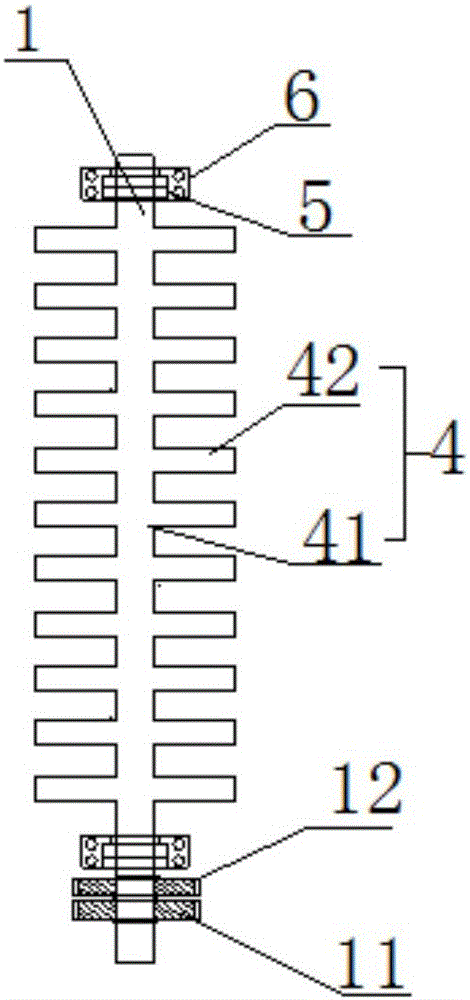

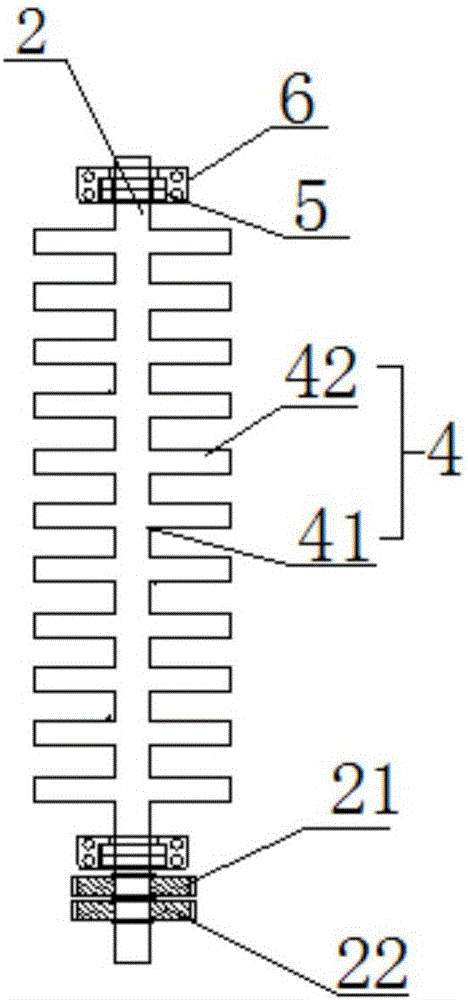

[0019] Such as figure 1 A rotary grate is shown, which includes a mounting seat, a shaft plate group A1, a shaft plate group B2 and a drive motor 3 respectively connected to the shaft plate group. The shaft plate group A and the shaft plate group B include toothed shaft plates 4 and gears, the toothed shaft plates 4 of the shaft plate group A and the shaft plate group B are arranged at intervals; the toothed shaft plate 4 is composed of a rotating shaft 41 and a toothed plate 42 arranged in a symmetrical array along the axis of the rotating shaft, which is welded or cast into an integral structure.

[0020] The toothed plates 42 of the adjacent two toothed shaft plates 4 are misaligned and leave gaps, the distance between the adjacent two toothed shaft plates 4 is greater than the length of the toothed plates 42, and the distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com